Overview, 1 < exaxt zr > system configuration, 1 system 1 – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 15: Overview -1, Exaxt zr > system configuration -1 1.1.1, System 1 -1

<1. Overview>

1-1

IM 11M12A01-02E

8th Edition : Jan.13,2012-00

1.

Overview

The EXAxt ZR Separate type Zircon Oxygen Analyzer is used to monitor and control the oxygen

concentration in combustion gases, in boilers and industrial furnaces, for wide application

in industries which consume considerable energy — such as steel, electric power, oil and

petrochemical, ceramics, paper and pulp, food, or textiles, as well as incinerators and medium/

small boilers. It can help conserve energy in these industries.

The EXAxt ZR also contributes to preservation of the earth’s environment in preventing global

warming and air pollution by controlling complete combustion to reduce CO

2

, SOx and NOx.

The ZR22G Separate type Detector uses a high-reliability Zirconia sensor, and its heater

assembly can be replaced on site. The detector is mounted, for example, on the wall of a flue and

can measure the gases directly.

For use in combustion gases at temperatures up to 1400 °C, choose the general use 0.15 m

long detector, which is combined with the ZO21P, the high temperature probe protector. The

converter is equipped with an LCD touch screen which has various setting displays, a calibration

display, oxygen concentration trend display, with easier operation and improvement of display

functions. The converter is equipped with various standard functions such as measurement and

calculation as well as maintenance functions including self-test. Analyzer calibration can also

be fully automated — and the ZR40H, an automatic calibration unit, is available. Choose the

detector version which best suits your needs so that an optimal combustion control system can

be obtained.

Some examples of typical system configurations are illustrated below:

1.1

< EXAxt ZR > System Configuration

The system configuration should be determined by the conditions; e.g. whether calibration is

to be automated, and whether flammable gas is present and requires safety precautions. The

system configuration can be classified into three basic patterns as follows:

1.1.1

System 1

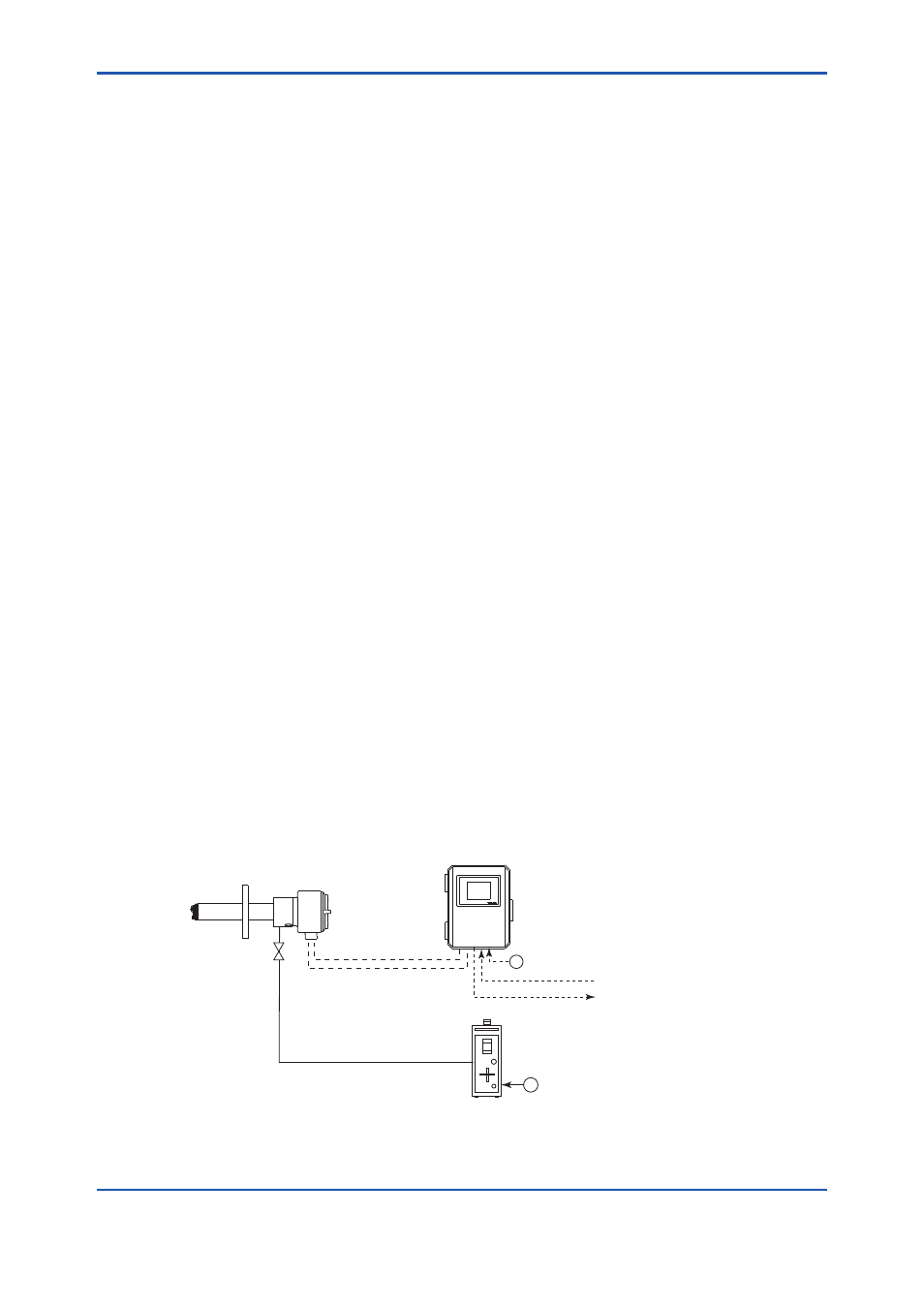

This is the simplest system consisting of a detector and a converter. This system can be

implemented for monitoring oxygen concentration in the combustion gases of a package boiler.

No piping is required for the reference gas (air) which is fed in at the installation site. The handy

the ZO21S standard gas unit is used for calibration.

Zero gas from this unit and span gas (air) is sent to the detector through a tube which is

connected during calibration.

EXA ZR402G

ZR22G Separate type

Zirconia Oxygen Analyzer, Detector

ZR402G Converter

Stop valve

Calibration gas

ZO21S Standard gas unit

~

100 to

240 V AC

F1-1E.ai

Contact input

Analog output, contact output

(Digital output HART)

Signal

(6-core shield cable)

Heater(2-core)

~

Figure1.1