5 heat spread, Pread – IEI Integration ICE-DB-9S User Manual

Page 113

ICE Module

Page 100

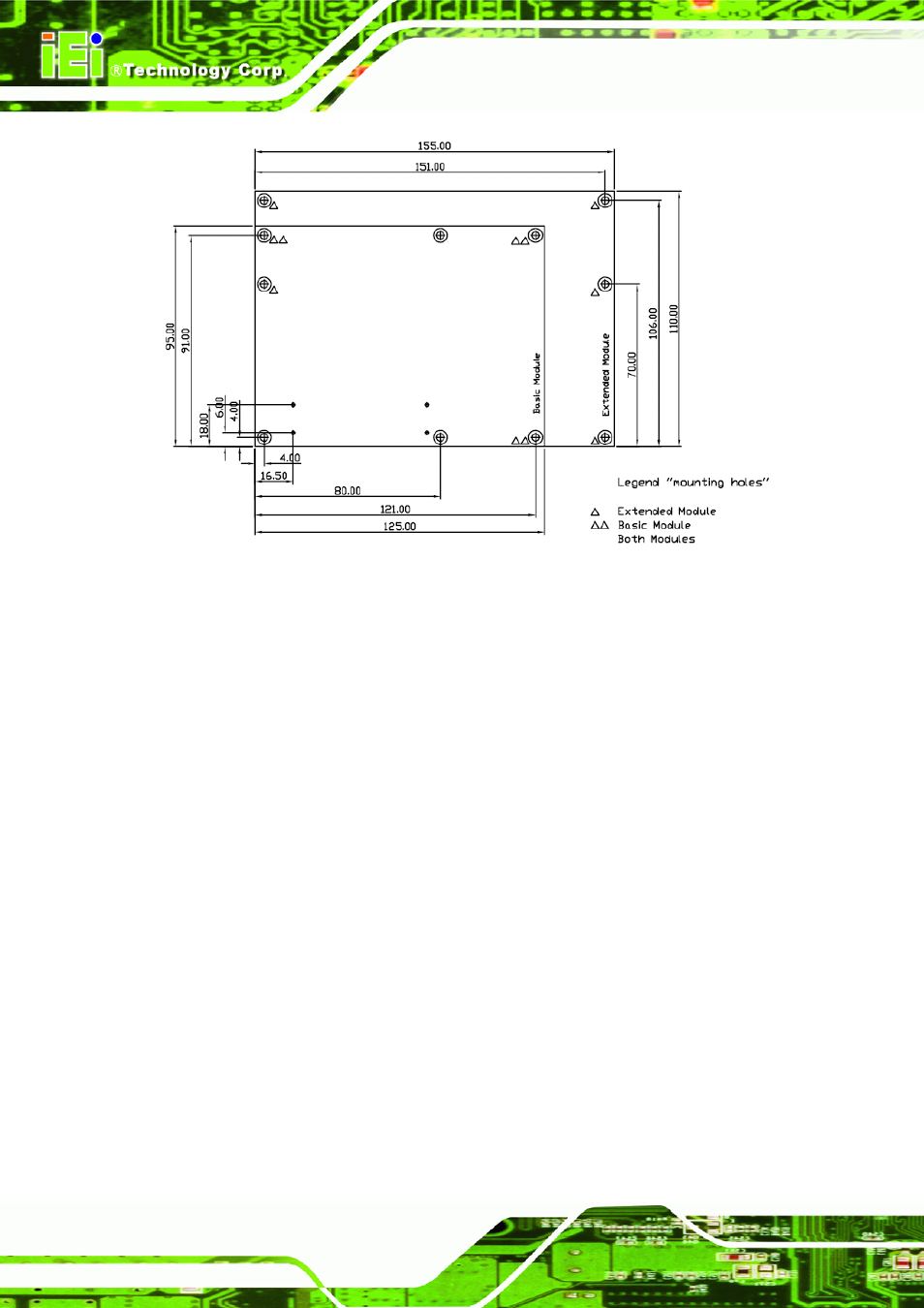

Figure 6-5: Compact, Basic and Extended Form Factor

6.5 Heat Spread

An important factor for each system integration is the thermal design. The

heatspreader acts as a thermal coupling device to the Module. Usually It is a 3mm

thick aluminum plate. The heatspreader is thermally coupled to the CPU via a thermal

gap filler and on some Modules it may also be thermally coupled to other heat

generating components with the use of additional thermal gap fillers. Although the

heatspreader is the thermal interface where most of the heat generated by the Module

is dissipated, it is not to be considered as a heat sink. It has been designed to be used

as a thermal interface between the Module and the application specific thermal

solution.

The application specific thermal solution may use heat sinks with fans, and/or heat

pipes, which can be attached to the heatspreader. Some thermal solutions may also

require that the heatspreader is attached directly to the systems chassis therefore

using the whole chassis as a heat dissipater. The main mechanical mounting solutions

for systems based on COM Express Modules have proven to be the 'top-mounting'

and 'bottom-mounting' solutions. The decision as to which solution will be used is

determined by the mechanical construction and the cooling solution of the customer's

system. There are two variants of the heatspreader, one for each mounting possibility.