Operation – IAI America PSEP User Manual

Page 79

73

/

3.

Operation

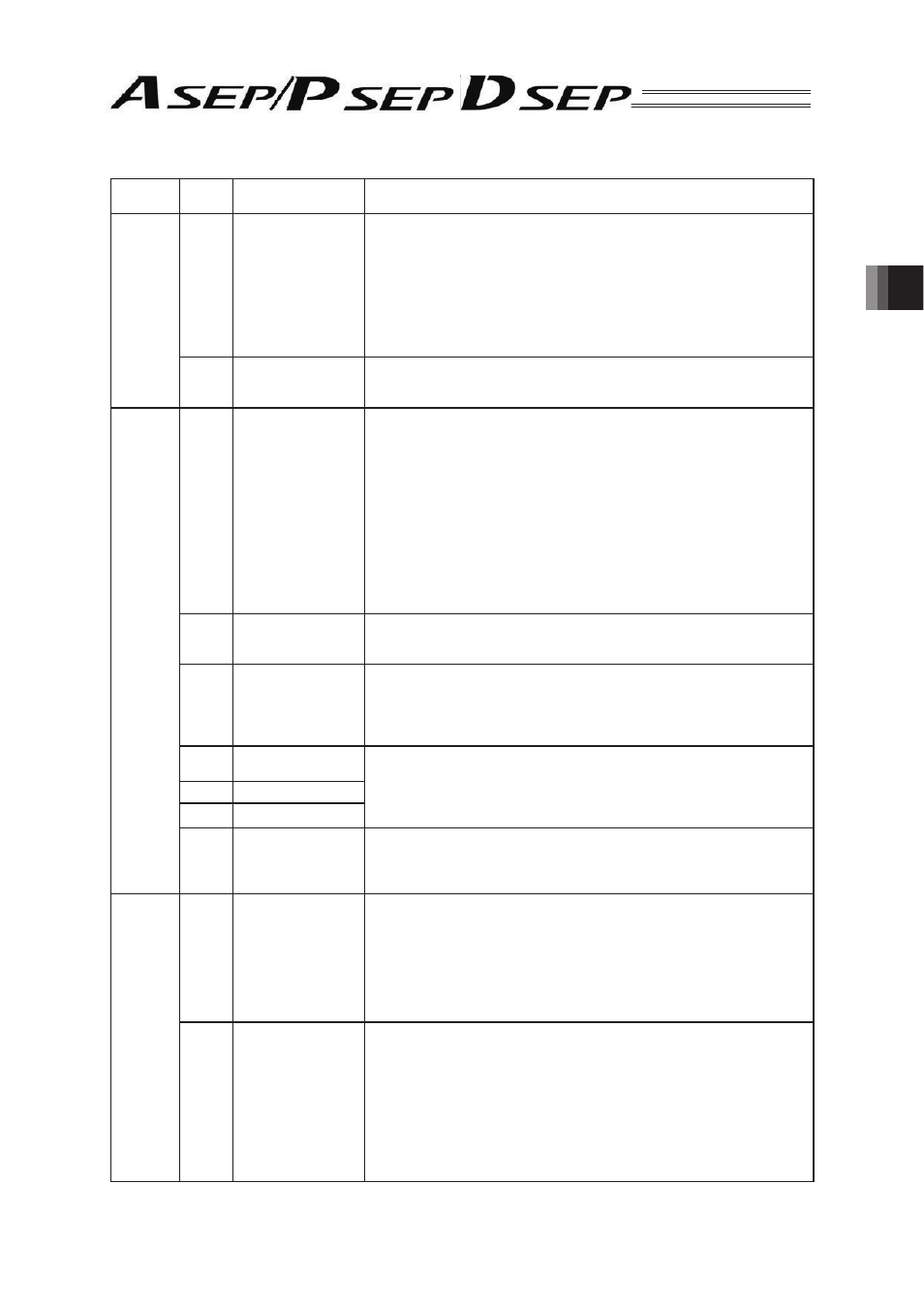

Error

Level

Code

Alarm Name

Cause/Treatment

Operation

Cancellation

0D9

Software Stroke Limit-

Over Error

Cause :

(1)

In the case that the actuator is vertically installed and the target position is close

to the soft limit, because the load is too high, or the deceleration setting is too

high, an over-chute might occur and the actuator might exceed the soft limit.

(2)

The actuator is moved out of the soft limit range when the servo-motor is turned

OFF, and then the servo-motor turning ON operation is performed.

Treatment :

(1)

Set the deceleration curve so that an over-chute is not caused when the actuator

is stopped.

(2)

Return the actuator within the soft limit range and perform the servo-motor

turning ON operation.

0DC

Pressing Motion Range

Over Error

This alarm is generated when the reaction force after the pressing operation complete is too high

and the actuator is pushed back to the start point of pressing operation. Revise the construction

of the whole system.

Cold Start

0E0

Overload

Cause :

(1) The load is increased too much due to a external force.

(2) In the case of the unit with the brake, the brake is not released.

(3) The actuator’s sliding resistance might be partly too large.

Treatment :

(1) In the case that an abnormal external force is impressed, remove it.

(2)

Check that the brake is released when the servo-motor is turned ON. If not, a

breakdown of the brake, cable breakage, or defective part inside the controller,

etc., is considered.

(3)

In the case that the work can be moved by hand, move it. Then, check that there

is no location where a sliding resistant is too large.

If the error is caused by the above item (2) or (3), contact our company.

Note :

Restart the operation after making sure to remove the cause. Also, in the case that

the power is turned OFF, turn ON the power again after 30 minutes or to prevent

motor coil burning.

0E5

Encoder Signal Receipt

Error

Cause :

The missing connector inside the controller is considered.

Treatment :

In the case that the same error is caused after the power to the controller is re-input,

contact our company.

0E7

A, B or Z-phase Wire

Breakage

The encoder signal is not detected normally.

Cause :

A looseness or wire breakage in the connector section of the actuator connecting

cable is considered.

Treatment :

Check for the connection condition of the actuator connecting cable and perform the

continuity test. If normal, contact our company.

0E8

A or B-phase Wire

Breakage

The encoder signal is not detected normally.

Cause :

A looseness or wire breakage in the connector section of the actuator connecting

cable is considered.

Treatment :

Check for the connection condition of the actuator connecting cable and perform the

continuity test. If normal, contact our company.

0E9

A -phase Wire Breakage

0EA

B-phase Wire Breakage

0EC

PS-phase Wire Breakage

Cause :

A looseness or wire breakage in the connector section of the actuator connecting

cable is considered.

Treatment :

Check for the connection condition of the actuator connecting cable and perform the

continuity test. If normal, contact our company.

Operation

Cancellation

0ED

Absolute Encoder Error

Detection 1

Cause :

(1)

When the absolute unit reset is completed and the power is re-input, the current

position might be changed due to an external force.

(2)

When the absolute unit is reset, the current position might be changed due to an

external force.

Treatment :

(1)

Turn OFF the power and arrange so that a vibration is not added to the actuator

and turn ON the power again.

(2)

Arrange so that a vibration is not added to the actuator and perform the home

return operation again.

0EE

Absolute Encoder Error

Detection 2

&DXVH

,WPLJKWEHFDXVHGLQWKHVLPSOL¿HGDEVROXWHW\SHZKHQWKHSRZHULVWXUQHG21

IRUWKH¿UVWWLPHDIWHUWKHEDWWHU\LVFRQQHFWHG

(2) The battery voltage is too much decreased to keep the encoder counter operation.

(3)

The encoder cable is disconnected during the power failure, or a wire breakage

occurs in the encoder cable.

(4) The parameter is changed.

Treatment :

In the case of (1), (2) or (4), perform the Absolute Reset operation according to the

procedure.

6XSSO\WKHSRZHUIRUKRXUVRUPRUHWRFKDUJHWKHEDWWHU\VXI¿FLHQWO\DQGWKHQ

perform the Absolute Reset operation.