Operation – IAI America PSEP User Manual

Page 78

72

/

3.

Operation

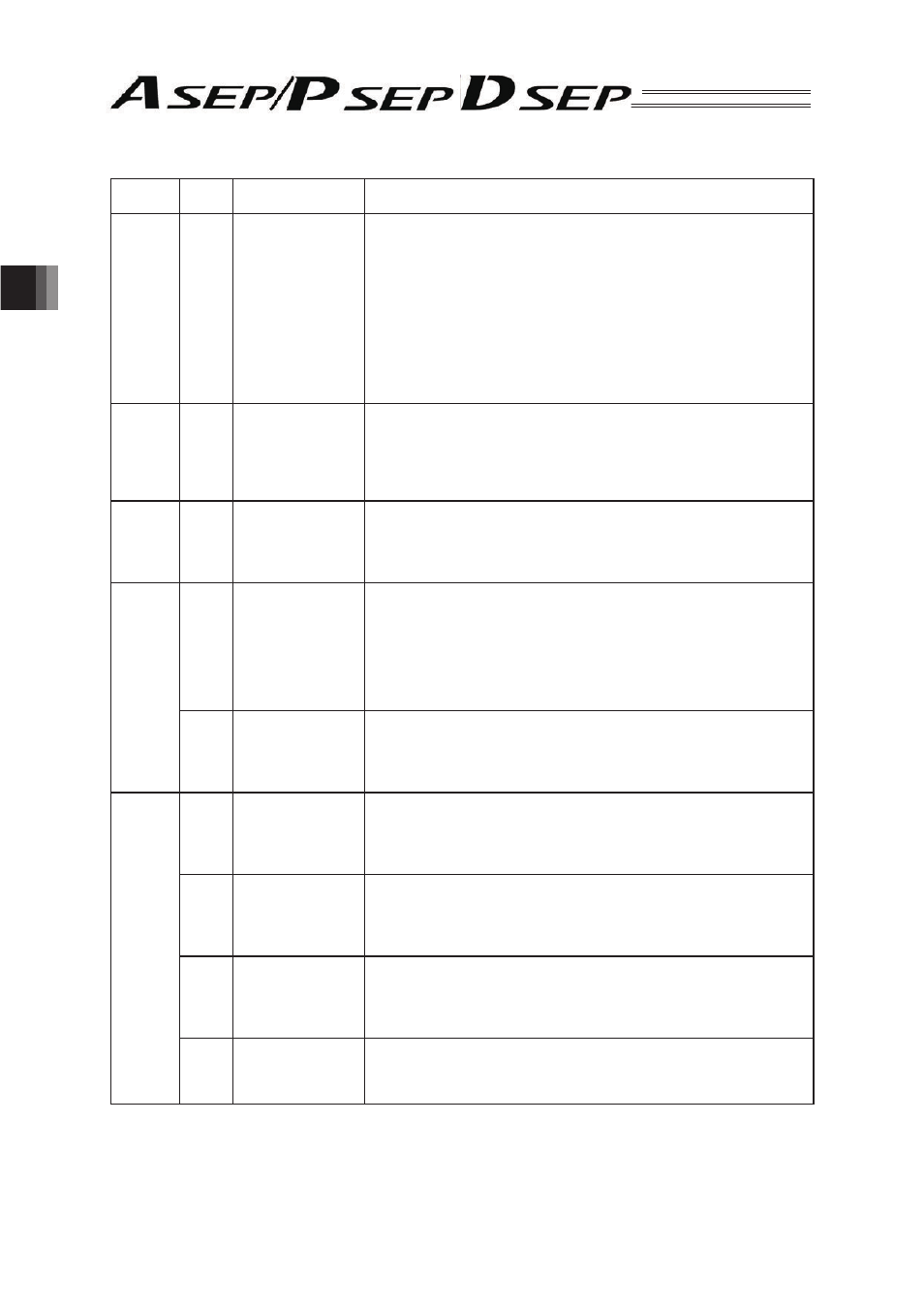

Error

Level

Code

Alarm Name

Cause/Treatment

Operation

Cancellation

0C1

Servo-Motor Error

The motor operation is not available for 2 seconds or more after the movement command is

received and before the actuator reaches the target position.

Cause :

(1)

A looseness in the connection section of the actuator connecting cable or wire

breakage is considered.

(2) In the case of the unit with the brake, the brake is not released.

(3) The motor load might be too large due to the external force.

(4) The sliding resistance in the actuator itself might be too large.

Treatment :

(1) and (2) Check for the actuator connecting cable wiring condition.

&RQ¿UPWKDWWKHUHLVQRHUURULQWKHPHFKDQLFDOSDUWDVVHPEO\FRQGLWLRQ

(4)

In the case that the load weight is normal, move the actuator by hand to check

the sliding resistance after the power is turned OFF. In the case that there is any

error in the actuator itself, contact our company.

Cold Start

0C8

Overcurrent

Cause :

The output current in the power circuit section is increased abnormally. The motor

coil insulation degradation might be considered.

Treatment :

Measure the resistance between the motor connecting cable U, V and W and

LQVXODWLRQUHVLVWDQFHZLWKHDUWKFDEOHDQGFRQ¿UPZKHWKHURUQRWWKHUHLVLQVXODWLRQ

degradation.

When the measurement is performed, consult with our company.

Operation

Cancellation

0C9

Overvoltage

An over-voltage is caused in the 24V input power (24V

20%: 28.8V or more).

Cause :

(1) The source voltage in the 24V power unit is too high.

(2) A breakdown of the part inside the controller is considered.

Treatment :

Check for the input source voltage.

In the case that the voltage is normal, contact our company.

Cold Start

0CA

Overheat

Cause :

(1) The temperature inside the controller is too high. (95

qC or more)

(2)

When the actuator is vertically installed, in the case that the deceleration setting

is too high when it is moved downward, the regenerative resistance energy

PLJKWEHLQVXI¿FLHQW

(3) The defective part inside the controller is considered.

Treatment :

(1) Lower the surrounding temperature around the controller.

(2)

Review the setting conditions so that the deceleration curve becomes linear.

In the case that the cause is not applicable to (1) or (2), contact our company.

0CB

Current Sensor Offset

Adjustment Error

An error is found in the current detection sensor in the initialization in the start-up operation.

Cause :

(1)

A breakdown of the current detection sensor or peripheral component is

supposed.

(2) An error in the offset adjustment is supposed.

Treatment :

A work (PC board) change or offset adjustment is required. Contact our company.

Operation

Cancellation

0CC

Control Power Source

Voltage Error

An over-voltage is caused in the 24V input power (24V

20%: 28.8V or more).

Cause :

(1) The source voltage in the 24V power unit is too high.

(2) A breakdown of the part inside the controller is considered.

Treatment :

Check for the input source voltage.

In the case that the voltage is normal, contact our company.

0CE

Control Power Source

Voltage Drop

The source voltage from the 24V power unit is decreased (24V

20%: 19.2V or less).

Cause :

(1) The source voltage from the 24V power unit is too low.

(2) A breakdown of the part inside the controller is considered.

Treatment :

Check for the input source voltage.

In the case that the voltage is normal, contact our company.

0D2

Motor Power Source

Voltage Excessive

An over-voltage is caused in the motor power source (24V

20%: 38V or more).

Cause :

(1) The source voltage in the 24V power unit is too high.

(2) A breakdown of the part inside the controller is considered.

Treatment :

Check for the input source voltage.

In the case that the voltage is normal, contact our company.

0D8

'HÀHFWLRQ2YHUÀRZ

7KHSRVLWLRQGHYLDWLRQFRXQWHULVRYHUÀRZQ

Cause :

The velocity might be lowered in the movement operation due to an external force.

7UHDWPHQW &RQ¿UPDERXWWKHORDGFRQGLWLRQVWKDWWKHZRUNGRHVQRWLQWHUIHUHZLWKDQ\REMHFW

nearby or the brake has been released, etc., and if any, remove the cause.