Operation – IAI America PSEP User Manual

Page 77

71

/

3.

Operation

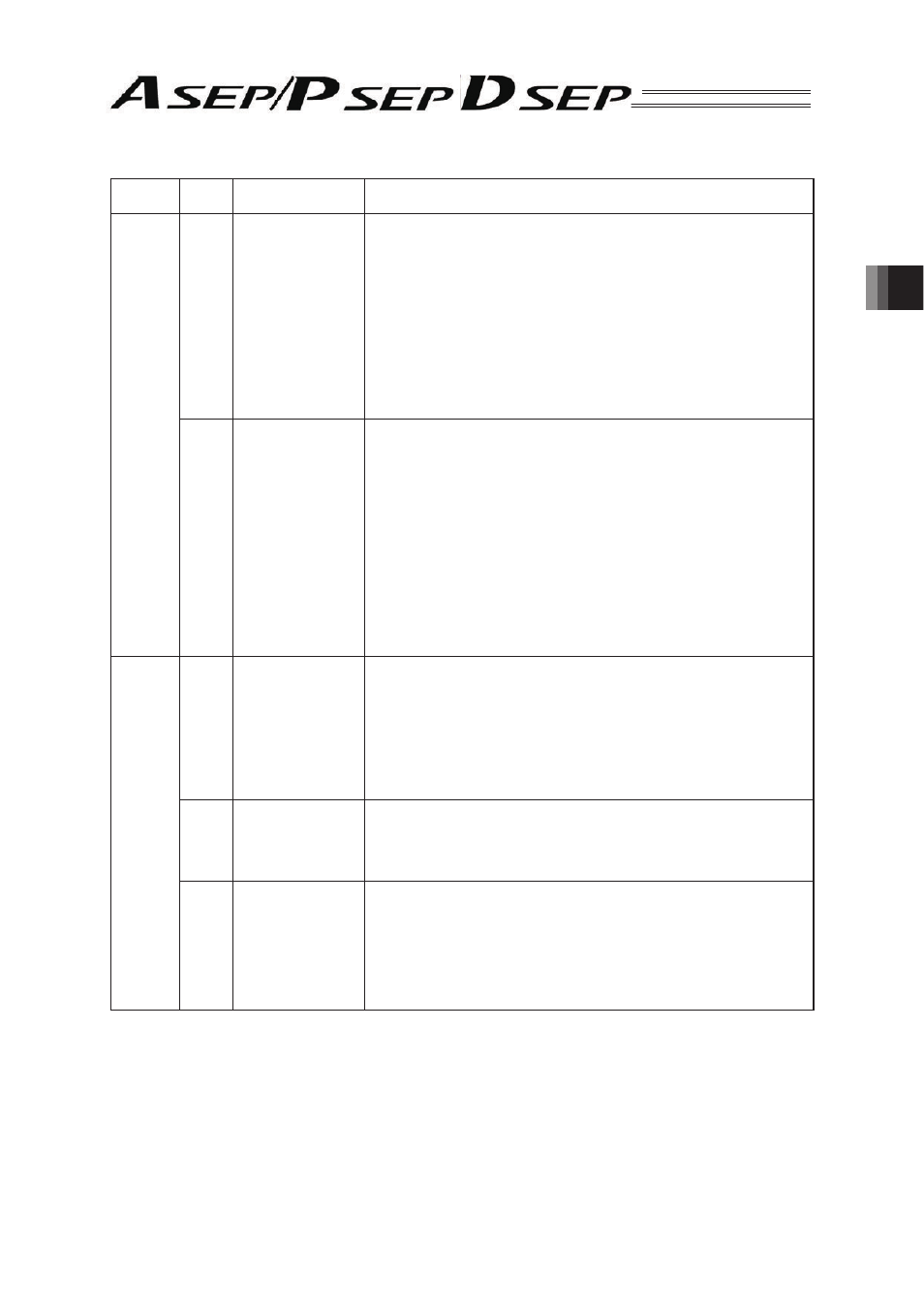

Error

Level

Code

Alarm Name

Cause/Treatment

Cold Start

0B7

Magnetic Pole

Indeterminate

)RUWKLVFRQWUROOHUZKHQWKHVHUYRPRWRULVWXUQHG21IRUWKH¿UVWWLPHDIWHUWKHSRZHULVLQSXW

the magnetic pole phase detection (pole sensing) is performed. At that time, the magnetic pole

SKDVHLVQRWGHWHFWHGDIWHUWKHVSHFL¿HGWLPHSHULRG

Cause :

(1)

A looseness in the connection section of the actuator connecting cable or wire

breakage is considered.

(2) In the case of the unit with the brake, the brake is not released.

(3) The motor load might be too large due to the external force.

(4) The sliding resistance in the actuator itself might be too large.

Treatment :

(1) and (2) Check for the actuator connecting cable wiring condition.

&RQ¿UPWKDWWKHUHLVQRHUURULQWKHPHFKDQLFDOSDUWDVVHPEO\FRQGLWLRQ

(4)

In the case that the load weight is normal, move the actuator by hand to check

the sliding resistance after the power is turned OFF. In the case that there is any

error in the actuator itself, contact our company.

0B8

Excitement Detection

Error

)RUWKLVFRQWUROOHUZKHQWKHVHUYRPRWRULVWXUQHG21IRUWKH¿UVWWLPHDIWHUWKHSRZHULVLQSXW

WKHPDJQHWLFSROHSKDVHGHWHFWLRQSROHVHQVLQJLVSHUIRUPHG+RZHYHUWKHVSHFL¿HGHQFRGHU

VLJQDOOHYHOLVQRWGHWHFWHGDIWHUWKHH[FLWHPHQWIRUWKHVSHFL¿HGWLPHSHULRG

Cause :

(1)

A looseness in the connection section of the actuator connecting cable or wire

breakage is considered.

(2) In the case of the unit with the brake, the brake is not released.

(3) The motor load might be too large due to the external force.

(4) The power is input while the actuator hits the mechanical end.

(5) The sliding resistance in the actuator itself might be too large.

Treatment :

(1) and (2) Check for the motor connecting cable wiring condition.

&RQ¿UPWKDWWKHUHLVQRHUURULQWKHPHFKDQLFDOSDUWDVVHPEO\FRQGLWLRQ

(4) Move the actuator away from the mechanical end and re-input the power.

(5)

In the case that the load weight is normal, move the actuator by hand to check

the sliding resistance after the power is turned OFF. In the case that there is any

error in the actuator itself, contact our company.

Operation

Cancellation

0BA

Home Position Sensor

Indetectable

For the actuator for which the home return sensor is used, the home return operation has not

been completed normally.

Cause :

(1)

The work interferes with the surrounding object in the course of the actuator’s

home return operation.

(2) The actuator’s sliding resistance might be partly too high.

(3)

The home return check sensor installation error, breakdown or wire breakage is

supposed.

Treatment :

In the case that the work does not interfere with anything, the cause (2) or (3) is

supposed. In such case, contact our company.

0BE

Home Return Time Out

&DXVH

(YHQZKHQWKHVSHFL¿HGWLPHSHULRGKDVSDVVHGDIWHUWKHKRPHUHWXUQRSHUDWLRQ

start, the home return operation is not completed (It never occurs in the normal

operation).

Treatment :

It is considered that the combination of the controller and actuator is not correct.

Contact our company.

0C0

Actual Speed Excessive

Cause :

The motor speed exceeds the maximum motor speed set using the maker’s set

parameters.

(1) The actuator’s sliding resistance might be partly too high.

(2)

The load is increased too much due to the momentary external force.

It might be caused when the load is lightened before detecting the servo-motor

error due to the above causes (1) and (2), and the actuator is moved suddenly.

Treatment :

Check that there is no error in the mechanical part assembly condition.

In the case that there is any error in the actuator itself, contact our company.