2 alarm codes and trouble shooting, Operation – IAI America PSEP User Manual

Page 76

70

/

3.

Operation

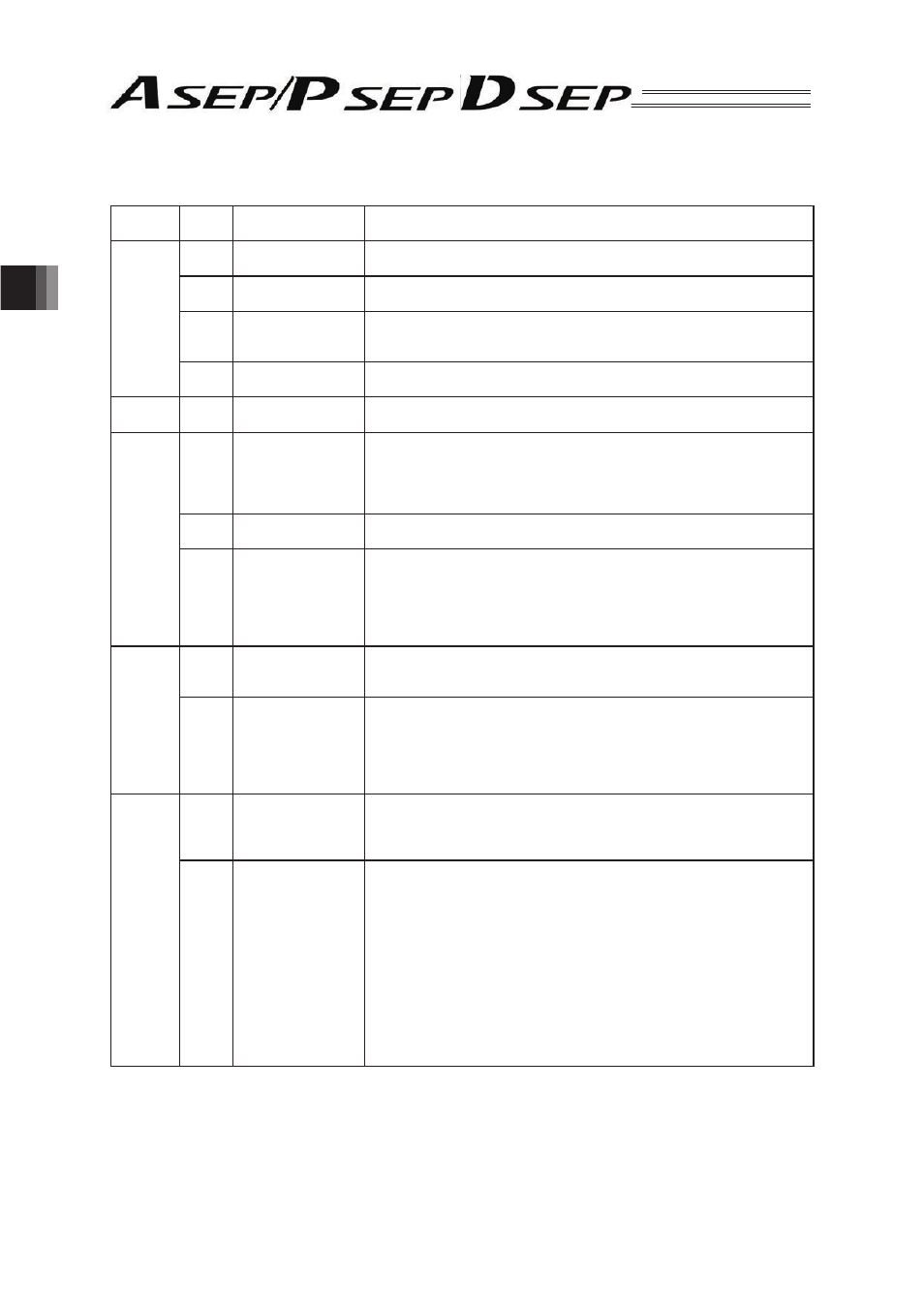

3.6.2 Alarm Codes and Trouble Shooting

Error

Level

Code

Alarm Name

Cause/Treatment

Operation

Cancellation

080

Movement Command in

Servo-Motor OFF

Cause :

The movement command is input while the servo-motor is turned OFF.

Treatment :

Input “SON” signal to turn ON the servo-motor.

082

Movement Command in

Incomplete Home Return

Cause :

The movement command is input while the home return has not been completed.

Treatment :

Input ST0 signal to perform the home return operation.

084

Movement Command

during Home Return

Operation

Cause :

The movement command is input during the home return operation.

7UHDWPHQW ,QSXWWKHFRPPDQGDIWHUFRQ¿UPLQJWKHKRPHUHWXUQFRPSOHWLRQ/6RU3(LV

turned ON).

085

Position Data Error in the

Movement

&DXVH

7KHYDOXHFRUUHVSRQGLQJWRWKHVSHFL¿HGSRVLWLRQLVQRWVHW

Treatment :

Set the effective value in the Position Setting operation.

Cold Start

0A1

Parameter Data Error

Cause :

The data input range in the parameter domain is not correct.

Treatment :

Change the value to the correct one referring to the user parameter table.

Operation

Cancellation

0A2

Position Data Error

Cause :

(1)

The movement command is issued while the target position has not set on the

Position Data.

(2) The target position value set on the Position Data exceeds the soft limit set value.

Treatment :

(1) Set the target position.

(2) Change the target position value to the one within the soft limit set value.

0A3

Position Command Data

Error

Cause :

The velocity value or acceleration value exceeds the maximum set value.

Treatment :

Change the value to the appropriate one.

0A7

Command Deceleration

Error

In the case that the velocity is changed (increased) close to the forward position or backward

position and the acceleration/deceleration has been set lower, the actuator might exceed the

soft limit.

Cause :

The command issue timing for velocity change during the movement, is too late.

Treatment :

Issue the command much earlier so that the actuator does not exceed the soft limit

and an over-chute is not caused.

Cold Start

0A8

Motor · Encoder Type not

Corresponding

Cause :

The type of the motor or encoder set to the parameter is not corresponding to the

system.

Treatment :

Redo the parameter settings.

0B4

Electric Angling

Mismatching

&DXVH

7KHSRVLWLRQGHYLDWLRQFRXQWHULVRYHUÀRZQ

7UHDWPHQW &RQ¿UPDERXWWKHORDGFRQGLWLRQVWKDWWKHZRUNGRHVQRWLQWHUIHUHZLWKDQ\REMHFW

QHDUE\RUWKHEUDNHKDVEHHQUHOHDVHGHWF$OVRWKHFRXQWHURYHUÀRZEHIRUH

the electric angle determination (in the Z-Phase Indetectable condition) can be

considered. In such case, the motor cable broken or encoder wire output error is

supposed, so check the cable connection.

Operation

Cancellation

0B5

Z-Phase Position Error

The position where the Z-phase is detected before the home return operation, is out of the

VSHFL¿HGUDQJH

Cause :

Encoder Error

Treatment :

Contact our company.

0B6

Z-Phase Detection Time

Out

)RUWKLVFRQWUROOHUZKHQWKHVHUYRPRWRULVWXUQHG21IRUWKH¿UVWWLPHDIWHUWKHSRZHULVLQSXW

the magnetic pole phase detection (pole sensing) is performed. At that time, the encoder

=SKDVHVLJQDOLVQRWGHWHFWHGDIWHUWKHVSHFL¿HGWLPHSHULRG

Cause :

(1)

A looseness in the connection section of the actuator connecting cable or wire

breakage is considered.

(2) In the case of the unit with the brake, the brake is not released.

(3) The motor load might be too large due to the external force.

(4) The sliding resistance in the actuator itself might be too large.

Treatment : (1) and (2) Check for the actuator cable wiring condition.

&RQ¿UPWKDWWKHUHLVQRHUURULQWKHPHFKDQLFDOSDUWDVVHPEO\FRQGLWLRQ

(4)

In the case that the load weight is normal, move the actuator by hand to check

the sliding resistance after the power is turned OFF. In the case that there is any

error in the actuator itself, contact our company.