Diagnosing mechanical engine conditions – Mityvac 06820 Diesel Compression Test Adapters User Manual

Page 8

Page Number - 8

Form 822378

DIAGNOSING

MECHANICAL ENGINE CONDITIONS

VACUUM GAUGE CHECKS &

DIAGNOSIS

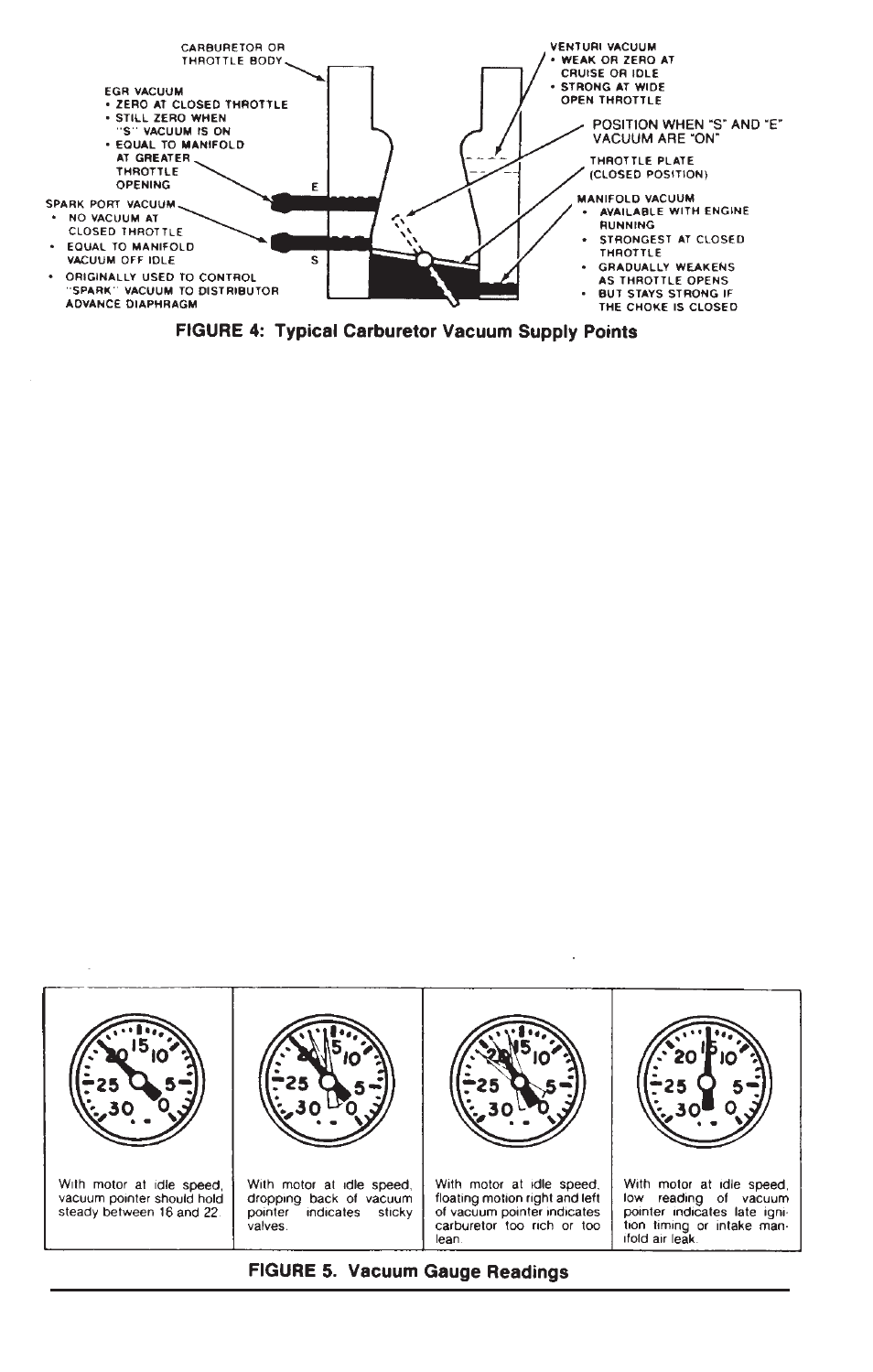

The pump’s vacuum gauge readings give

indications of possible mechanical

problems, but they are not foolproof.

Observe the gauge carefully and follow

the vacuum readings with further tests,

where possible, to confirm your diagno-

sis.

Do not look for the engine to produce

specific (numerical) amounts of vacuum.

Much more important than specific

numbers is the range of the vacuum

readings and the movement of the needle

(FIGURE 5). Important things to notice

about the needle movement are HOW the

needle moves (in a smooth or jerky

manner, erratic, etc.), what direction it

moves, whether movement is regular or

varying, and how far the needle moves.

The following gives some examples of

what to look for and the meanings of a

variety of vacuum gauge reading should

be 16-22” Hg and steady.

Normal Engine

Run engine at idle and connect the pump

to an intake manifold vacuum port. Watch

the needle’s movement on the gauge. At

idle, the vacuum gauge reading should be

16-22” HG and steady.

BURNED OR LEAKING

VALVE SPRING

At idle, burned or leaking valves will

cause the pointer on the gauge to drop to

a low reading and return to normal at a

regular interval. The needle will drop

from 1” Hg at regular intervals whenever

the defective valve attempts to close.