Electrical/vacuum solenoid, Thermal-controlled vacuum-switching valves, Service procedures – Mityvac 06820 Diesel Compression Test Adapters User Manual

Page 16

Page Number - 16

Form 822378

2) Record the vacuum reading, which

should be between 10-16” Hg.

3) Pinch off the vacuum hose and

observe if the gauge maintains the

vacuum level. If the gauge shows

that the vacuum drops with the hose

pinched off, the gauge or vacuum

hose has an external leak, which

must be corrected.

4) Now, connect the Black side of the

spark-delay valve to the vacuum

hose leading to the carburetor spark

port. Connect a section of vacuum

hose to your vacuum pump and

attach the other end to the distributor

end of the spark delay valve.

Observe the time in seconds for the

gauge to reach 6” Hg, with a 10-16”

Hg vacuum source. If the vacuum

reaches the 6” Hg level in less than

two seconds, regardless of type, the

SDV should be replaced. When

checking the valve, care must be

taken to prevent oil or dirt from getting

into the valve as this will impair its

function.

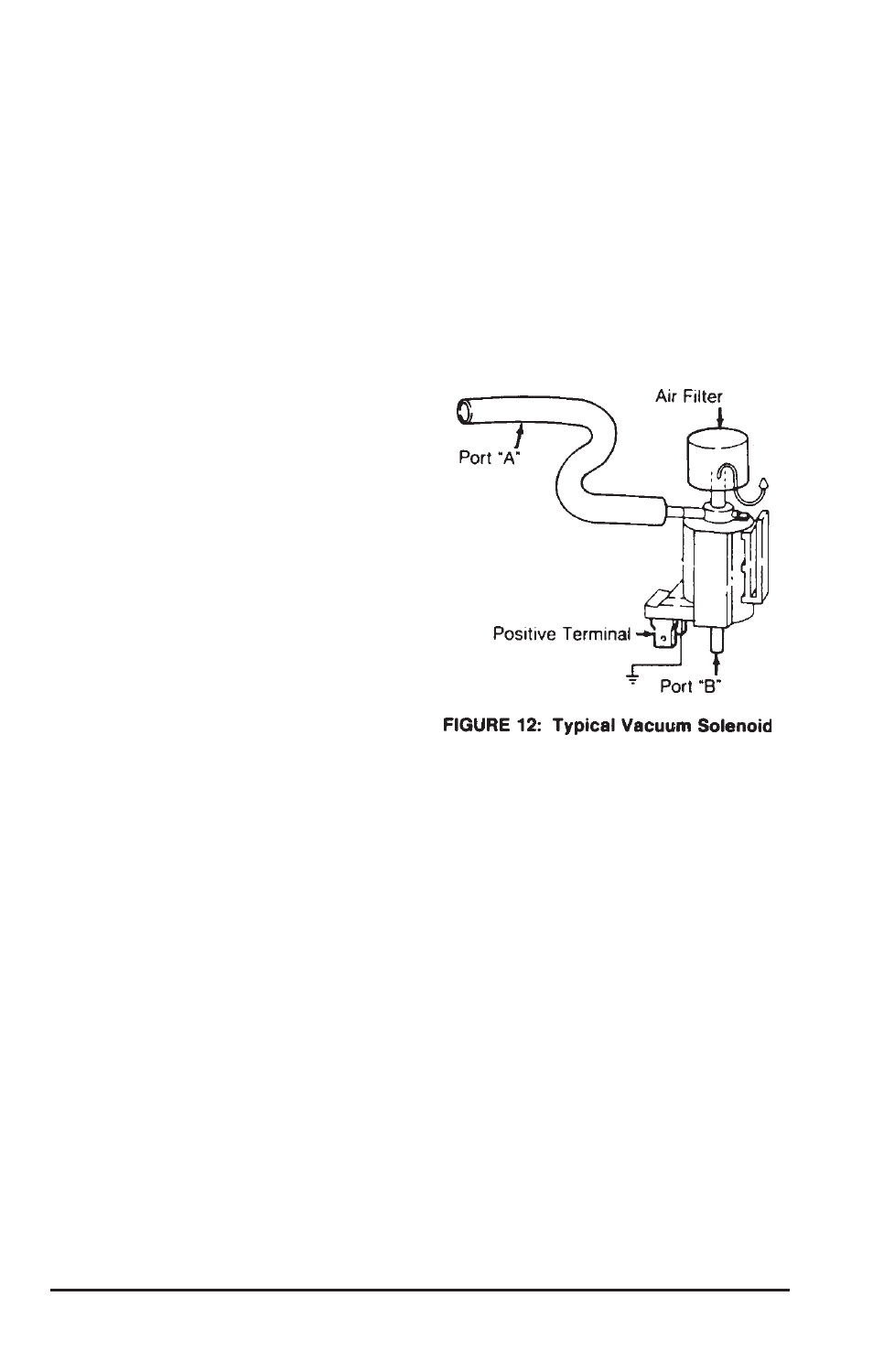

ELECTRICAL/VACUUM SOLENOID

SERVICE PROCEDURES

1) Disconnect vacuum and electrical

connectors from the solenoid.

Connect the pump to port “B” and

attempt to apply vacuum with pump.

Vacuum should be released through

port “A” (FIGURE 12).

2) Using jumper wires, connect negative

solenoid terminal to ground and apply

12 volts to the positive terminal. Apply

vacuum to port “B”. Vacuum should

hold and not bleed off. If the solenoid

does not hold vacuum, replace

solenoid.

3) With solenoid still energized, move

vacuum pump to port “A”. Attempt to

apply vacuum. Vacuum should be

released through the air filter and no

vacuum should be present at port “B”.

THERMAL-CONTROLLED VACUUM-SWITCHING VALVES

SERVICE PROCEDURES

These control valves are called Ported

Vacuum Switches (PVS) when used on

Ford engines. Thermal Ignition Control

(TIC) valves when used on Chrysler

products, and Distributor Thermal

Vacuum-Switches (DTVS) when used on

General Motors engines.

The two-port valve is used to stop EGR

while the engine is cold. This type of

thermal switch is needed to provide good

driveability by limiting the entrance of EGR

until the engine is warmed up.

The three-port valve is commonly called a

cooling system PVS because it switches

the vacuum source to the distributor from

ported to full intake vacuum.

The four-port valve has been used in some

Ford engines to bypass the spark delay

valve and cut out the EGR system when the

engine is cold.

SERVICE PROCEDURES

Follow this procedure to test the two-port

vacuum-switching valve:

1) Apply 10” Hg of vacuum to the bottom

port of the valve with your vacuum

pump and measure the results with a

second vacuum gauge as shown in the

accompanying illustration (FIGURE 13).

2) The valves are color coded and the

Green valve should open and pass

vacuum at 68° F, the Black valve at

100° F.