3 mounting in fl cold platefl technique, Mounting in ”cold plate” technique, Mechanical installation – Lenze 8400 User Manual

Page 129

Mechanical installation

Standard devices in the power range 3 ... 22 kW

Mounting in ”cold plate” technique

5

129

EDS84ASC552 EN 9.1

5.3.3

Mounting in ”cold plate” technique

The E84AVxxC... controllers are designed for assembly on coolers (e.g. collective coolers) in

”cold-plate” technique.

Requirements for collective coolers

A good thermal connection to the cooler is important for the trouble-free operation of

the controller:

ƒ

The contact area between the collective cooler and the controller

– must be at least as big as the cooling plate of the controller.

– must be smooth, the maximum deviation must not exceed 0.05 mm.

ƒ

The collective cooler must be connected to the controller with all required screwed

joints.

ƒ

The thermal resistance R

th

must be observed, see table.

The values in the table apply to the operation of the controllers under rated

conditions.

The values include the heat transmission between the cooler and the device.

With a standard heat conducting paste and a film thickness of 50 m, the heat

transmission is approx.

– 0.03 K/W for controllers up to 5.5 kW

– 0.02 K/W for controllers up to 15 kW

– 0.01 K/W for controllers up to 22 kW.

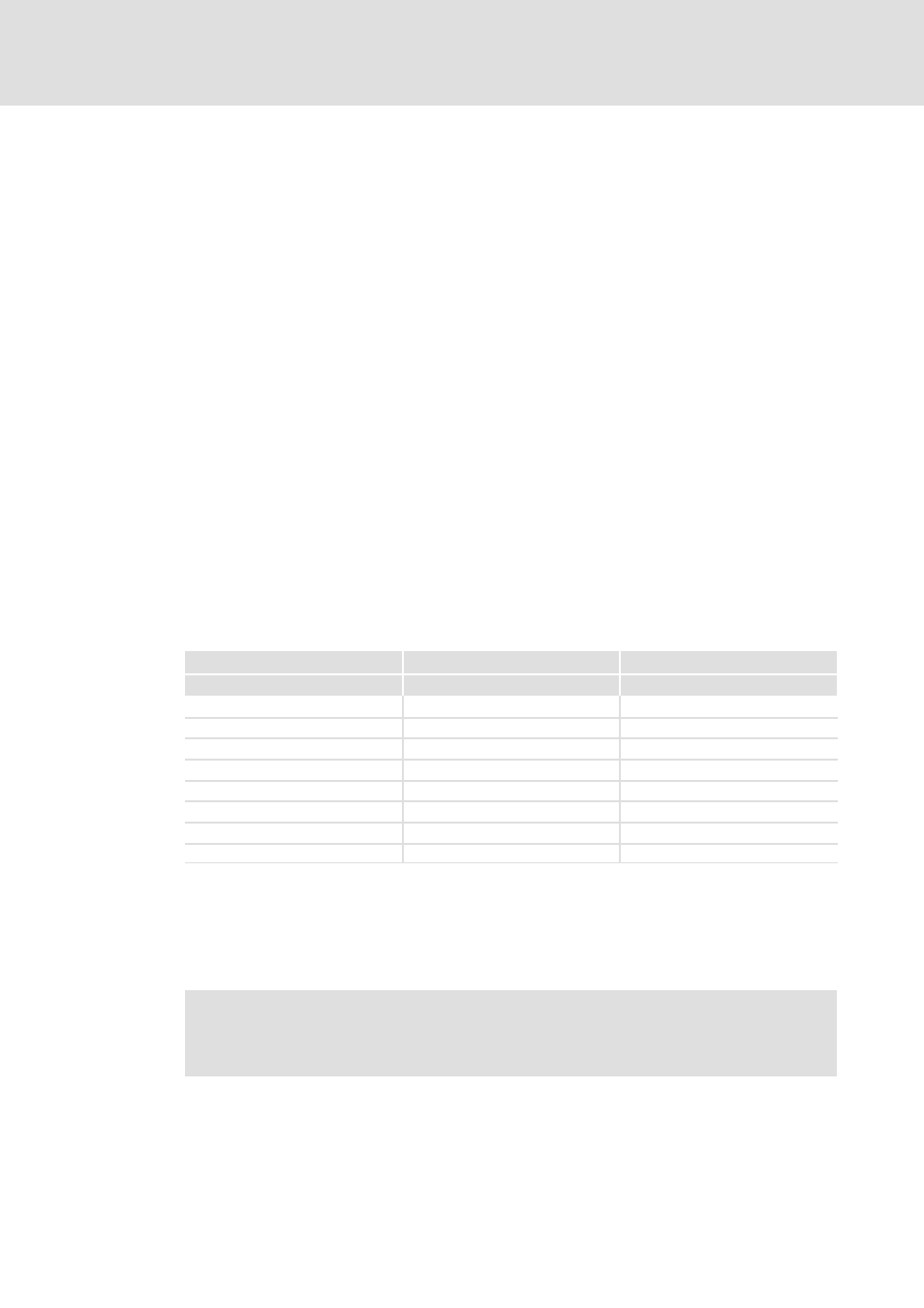

Power to be dissipated

Thermal resistance

Type

P

v [W]

R

th

[K/W]

E84AVxxC3024xx0

115

0.33

E84AVxxC4024

155

0.25

E84AVxxC5524

215

0.18

E84AVxxC7524

250

0.15

E84AVxxC1134

355

0.11

E84AVxxC1534

390

0.10

E84AVxxC1834

460

0.057

E84AVxxC2234

540

0.057

Ambient conditions

ƒ

The rated data and the derating factors at increased temperature also apply to the

ambient temperature of the drive controllers.

ƒ

Temperature at the cooling plate of the drive controller: max. 75 °C.

Note!

Apply standard heat-conducting paste or heat-conducting foil onto cooler and

cooling plate before you bolt the controller onto the cooler.