Nanodac – Carbolite nanodac User Manual

Page 99

nanodac™

97

MC27 –EN–1.04

Table 6.4.7 Calculate parameter values

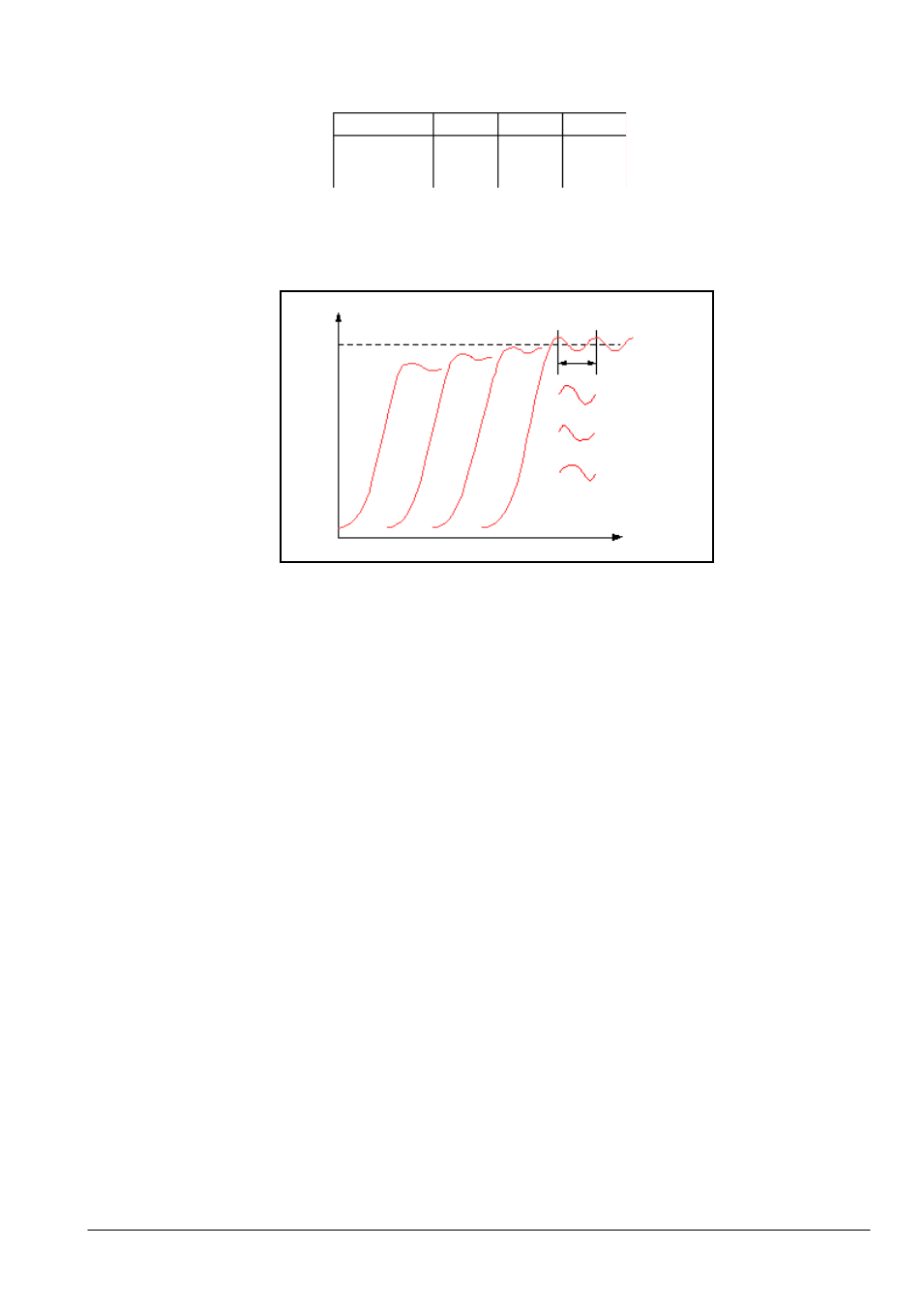

Figure 6.4.6a Relative Cool Gain

CUTBACK VALUES

The PID terms calculated from Table 6.4.7, above, should be entered before the cutback values are set.

The above procedure sets up the parameters for optimum steady state control. If unacceptable levels of

overshoot or undershoot occur during start-up, or for large step changes in PV, then the cutback

parameters should be set manually, as follows:

1.

Initially set the cutback values to one proportional bandwidth converted into display units. This can

be calculated by taking the value in percent that has been installed into the parameter ‘PB’ and

entering it into the following formula:

PB/100

Span of controller = Cutback High and Cutback Low

For example, if PB = 10% and the span of the controller is 0 to 1200°C, then

Cutback High = Cutback Low = 10/100

1200 = 120

Control type

PB

Ti

Td

Prop ortional only

P + I

P + I + D

2

PB

′

2.2

PB

′

1.7

PB

′

Off

Off

0.12

T

Off

0.8

T

0.5

T

Setpoint

R2G correct

R2G too large

R2G too small

Time

Te

m

p

er

atu

re