Konica Minolta bizhub PRESS C1100 User Manual

Page 209

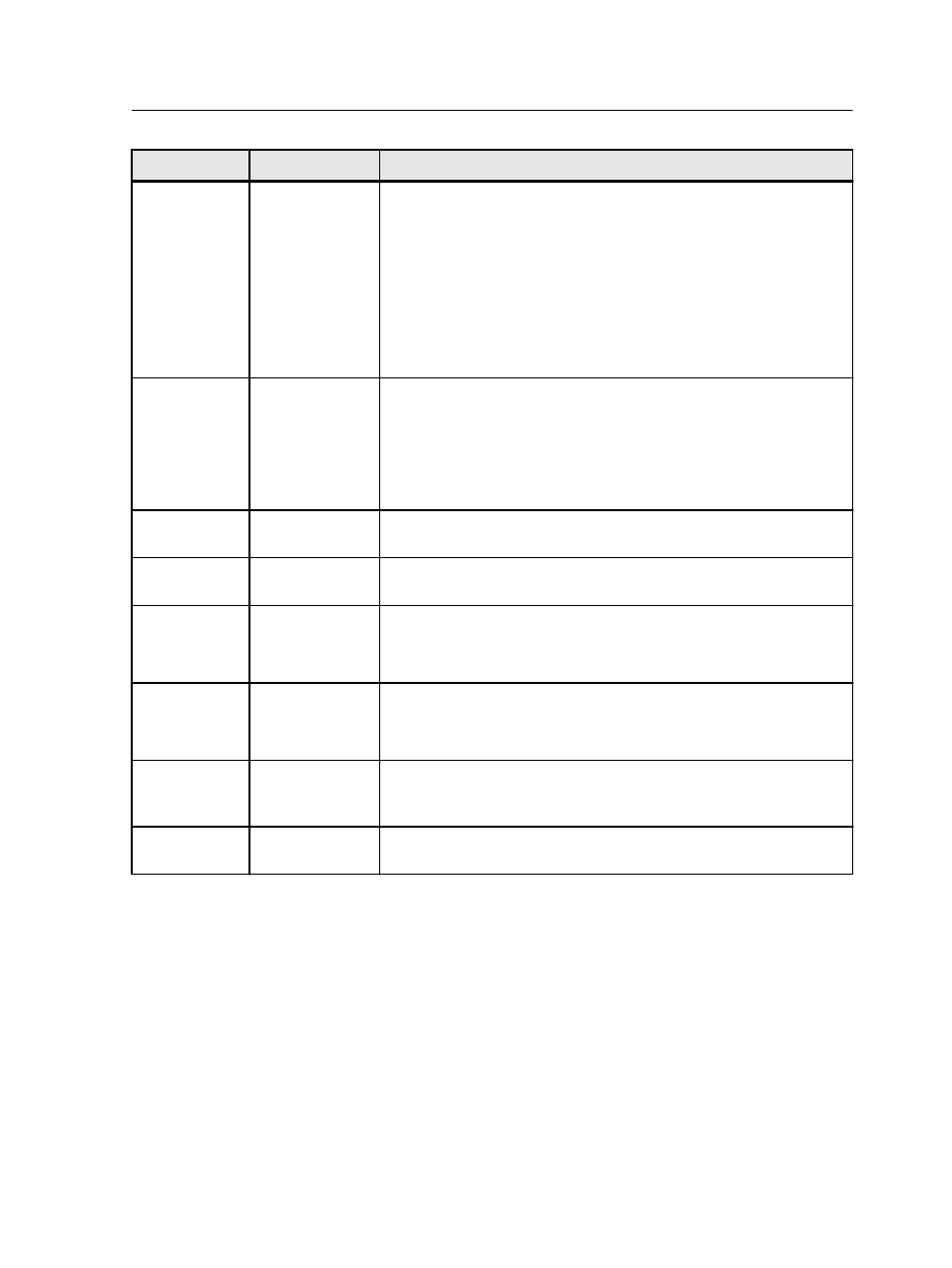

Parameter

Option

Description

Generate

corner mark

Select Generate corner mark to print correct corner marks on

sheets. The long line is parallel with the lead edge of a sheet and

the short line is perpendicular to the lead edge of a sheet.

The SCC measures distance both horizontally and vertically. Based

on measured distance, SCC manages slit positions, cut positions,

and crease positions. The Reference position is the start point to

measure the Finished size and the Crease position.

Note: When the CCD Scanner is not active, the actual corner of

each sheet is the starting point to measure distance.

Generate

barcode

Select Generate barcode to place the barcode in any corner of the

page with offsets and in front or back side of the sheet. Type the

distance in mm.

Note: The IC-312 print controller allows you to place the registration

mark and barcode in any corner of the page with offsets (in-track

and cross track).

Position

Generates a barcode in the following location of the page: Top right,

Top left, Bottom right, and Bottom left.

Side

Select the side where the barcode will be generated. Select Front

side or Back side.

Registration

line offset

Paper width direction—the whole registration mark is placed

within 3 mm -20 mm from the right edge.

Note: This option is available for the DC-645.

Corner mark

offset

The corner mark is placed in a range of 0 - 25 mm (horizontal and

vertical distance).

Note: This option is available for the DSF-2000.

Barcode offset

Paper feed direction—The whole barcode should be within 3 mm-

20 mm from lead edge Paper width direction: The whole barcode

should be within 25 mm - 60 mm from the right edge.

End mark

The Duplo DSF-2000 includes an end mark detector that can detect

collation and paper feed errors, and prevents binding errors.

Finishing tab in the job parameters window

199