8 workbench printer utility, 1 access the workbench printer utility, 8workbench printer utility – HID FARGO HDP5000 User Guide User Manual

Page 83

July 2013

Page 83 of 100

© 2012, 2013 HID Global Corporation. All rights reserved.

HDP5000 & HDPii Plus Card Printer Encoder User Guide_L000950, 3.0

Step

Procedure

3

a. Apply a strip of ½ (12mm) wide Scotch-type clear adhesive tape (such as 3M brand 600), at least

2 (50mm) long, firmly across the surface of the card, pressing out all air bubbles with a fingertip.

b. Remove the tape by smoothly and rapidly (approximately 2 inches/second (50mm/sec)) pulling it

up at a perpendicular (90 degree) angle to the card. (

Note: The IPC recommends a minimum of

three tests for each card type evaluation.)

4

Visually examine the card and the strip of tape pulled from the card, to see if any portion of the InTM

Film was removed from the card.

• If any residue (for example, oil or grease from fingertips) is present on the card surface, the

evaluation results may be affected.

• If the printed, transferred InTM Film particles (a) pull away from the card and (b) adhere to the

tape, this indicates that inadequate adhesion of the InTM Film to the card. Increased heat and

Dwell Times are necessary to resolve this problem.

5

If the tape test indicates inadequate adhesion, increase the heat setting by 5 degrees, print another

card and try the tape test again.

• Once the temperature has been increased 4 times (20 degrees), reset temperature to default and

increase the Dwell Time by .5 second.

• Repeat this process until adequate adhesion is achieved.

• Ensure that the cards (in use) have a surface roughness (Ra) of 60 micro inches or less.

This information should be available from the card manufacturer.

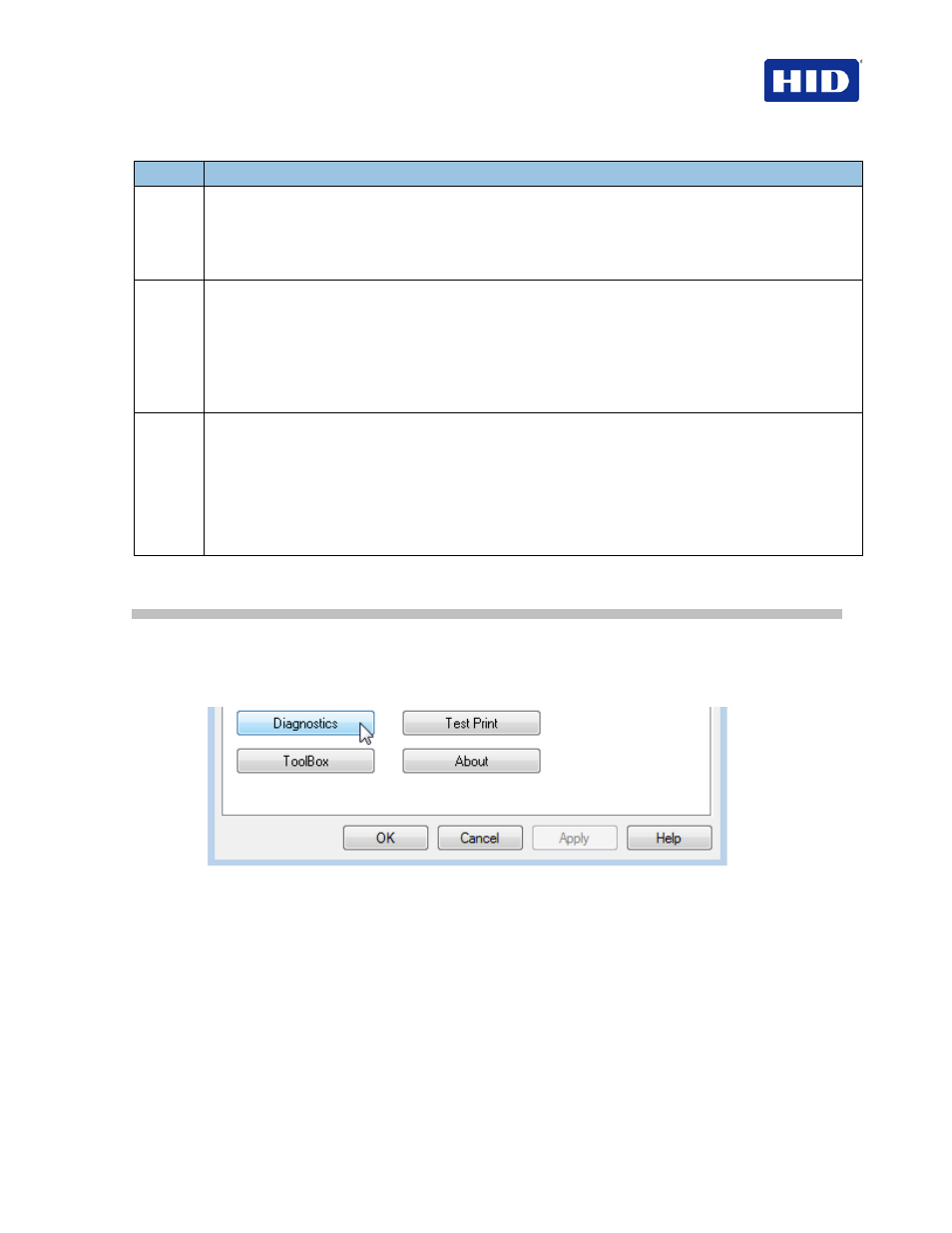

8

Workbench Printer Utility

See the

Workbench Printer Utility Help for additional information.

8.1

Access the Workbench Printer Utility

Click

Diagnostics to access the Workbench Printer Utility.

The Workbench Printer Utility displays. Find the Workbench Printer Utility User Guide on your

CD.