4 commissioning, 1 basic settings – NORD Drivesystems BU0700 User Manual

Page 58

NORDAC SK 700E Operating Manual

58

Subject to technical alterations

BU 0700 GB-1411

4 Commissioning

General information

Once the power supply has been connected to the frequency inverter, it will be operational after a few moments. In this

condition, the frequency inverter can be set up for the application requirements, i.e. parameterised. A complete and

comprehensive description of each parameter is set out in the following sections.

The motor should only be started with the enable signal after the parameters have been successfully set by qualified personnel.

ATTENTION: The frequency inverter is not equipped with a line main switch and is therefore always live when connected to

the power supply.

4.1 Basic settings

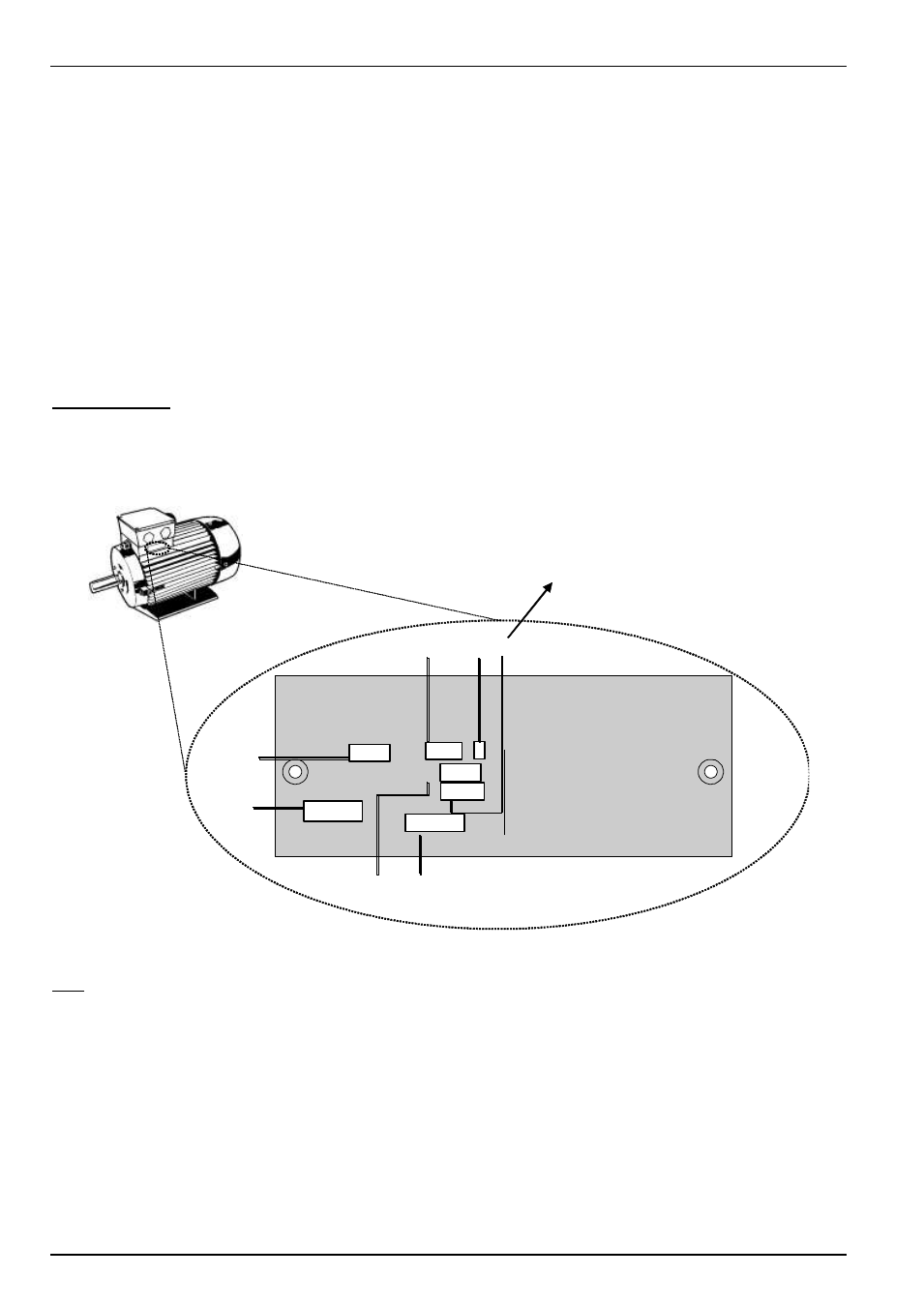

All frequency inverters supplied by Getriebebau NORD are pre-programmed with the factory setting for standard applications

with 4-pole standard motors. For use with other motors, the data from the rating plate of the motor must be input into the

parameters under the menu item >Motor data<.

Recommendation: It is necessary to input the most precise motor data (rating plate) possible for the correct use of the drive

unit. In particular, an automatic stator resistance measurement (P208) should be carried out.

3~ Mot

IEC 56

IM B3

cos

0,74

cos

0,74

IP55

Rot. KL 16

Th.Cl.F

EN60034

60 Hz

460 V Y

5,22 A

2,53 kW

1740 /min

1440 /min

P206

P201

P204

P203 P202

P200

9,0 /

5,22 A

50 Hz

2,2 kW

P207

P200 Motor list (valid up to 22kW):

0 = no changes

8 = 2,20 kW

1 = no motor

9 = 3,00 kW

2 = 0,25 kW

10 = 4,00 kW

3 = 0,37 kW

11 = 5,50 kW

4 = 0,55 kW

12 = 7,50 kW

5 = 0,75 kW

13 = 11,0 kW

6 = 1,10 kW

14 = 15,0 kW

7 = 1,50 kW ....

230/

400 V

/

Y

Note:

In this example, the motor must be "star" wired (400V, P207 = 0).

The frequency inverter is pre-programmed at the factory for standard applications using 4-pole DC standard motors. If another

NORD motor is to be used, it can be selected from a motor list in P200. The data is automatically loaded into parameters P201

– P208 and can be compared again with the data from the motor rating plate.

When using other motors, the data from the rating plate of the motor must be input into parameters P201 to P208.

In order to automatically determine the stator resistance, set P208 = 0 and confirm by pressing "ENTER". The value adjusted to

the line resistance will be saved (dependent upon P207).