5 colour and contact assignments for the encoder – NORD Drivesystems BU0700 User Manual

Page 57

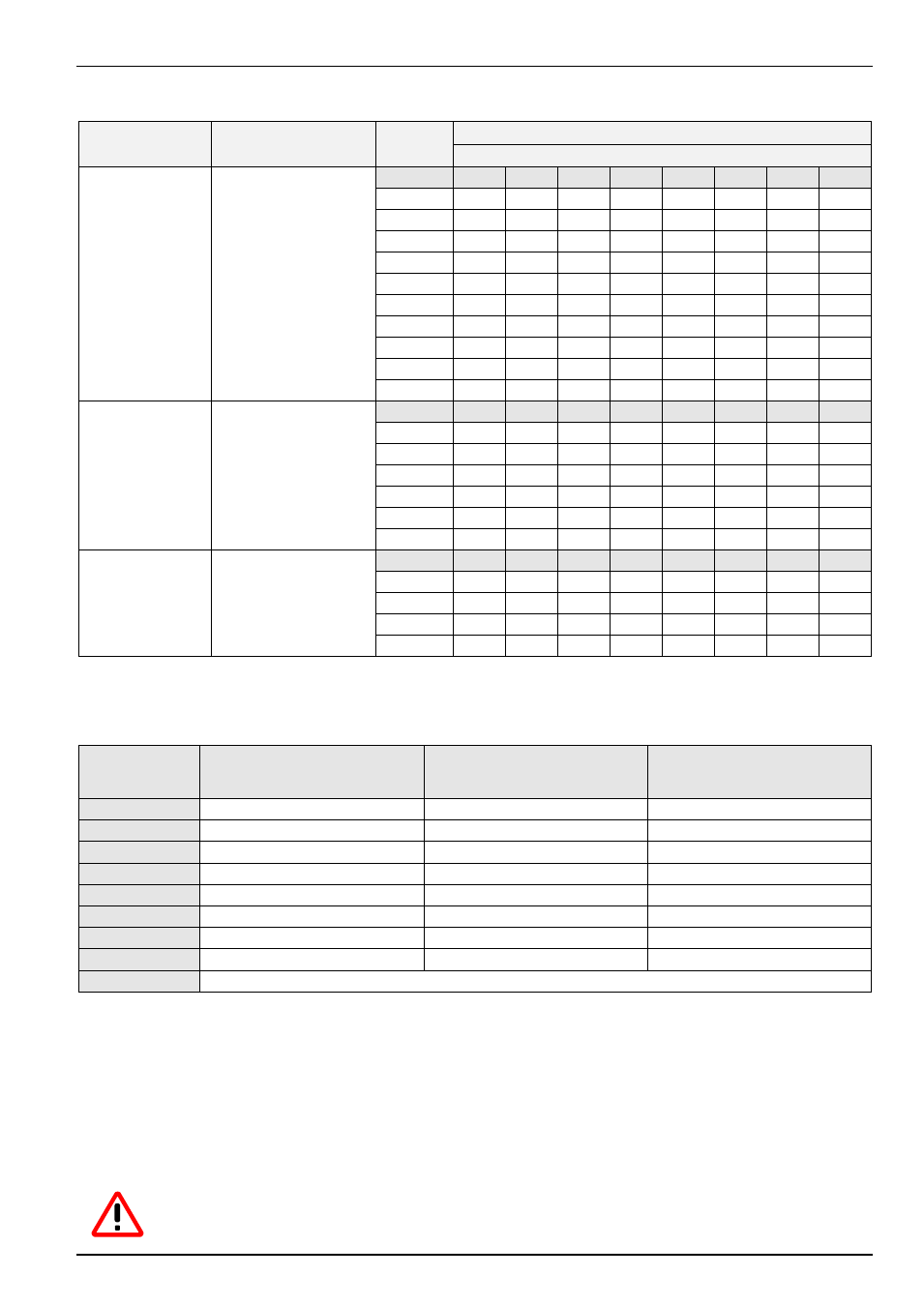

3.4 Klemmebelegung

BU 0700 GB-1411

Subject to technical alterations

57

Function

Data

Desig-

nation

Customer Units / Special Extension Units

Terminal

Serial interface

Electrically isolated input

Transfer rate USS up to

38400 Baud

Transfer rate CAN up to 500

kBaud

Transfer rate Profibus up to

1.5 Mbaud

Profibus 24V

12 MBaud

BSC

STD

MLT

USS

CAN

PBR

POS

ENC

RS485 +

-

X1.4.73

-

X4.3.73

-

-

-

-

RS485 -

-

X1.4.74

-

X4.3.74

-

-

-

-

CAN1 H

-

-

-

-

X5.3.75

-

-

-

CAN1 L

-

-

-

X5.3.76

-

-

-

PBR A

-

-

-

-

-

X6.3.81

-

-

PBR B

-

-

-

-

-

X6.3.82

-

-

PBR RTS

-

-

-

-

-

X6.3.83

-

-

PBR A

-

-

-

-

-

X6.4.81

-

-

PBR B

-

-

-

-

-

X6.4.82

-

-

SHIELD

-

-

-

-

-

X6.4.90

-

-

Incremental encoder

TTL, RS 422

max. 250kHz

500

– 8192 pulse/revolution

BSC

STD

MLT

USS

CAN

PBR

POS

ENC

ENC1 A+

-

-

-

-

-

-

X10.4.51 X11.2.51

ENC1 A-

-

-

-

-

-

-

X10.4.52 X11.2.52

ENC1 B+

-

-

-

-

-

-

X10.4.53 X11.2.53

ENC1 B-

-

-

-

-

-

-

X10.4.54 X11.2.54

ENC1 N+

-

-

-

-

-

-

X10.4.55

-

ENC1 N-

-

-

-

-

-

-

X10.4.56

-

Absolute encoder

SSI, RS 422

24 bit

BSC

STD

MLT

USS

CAN

PBR

POS

ENC

SSI1 CLK+

-

-

-

-

-

-

X10.3.63

-

SSI1 CLK-

-

-

-

-

-

-

X10.3.64

-

SSI1 DAT+

-

-

-

-

-

-

X10.3.65

-

SSI1 DAT-

-

-

-

-

-

-

X10.3.66

-

3.5 Colour and contact assignments for the encoder

Function

Cable colours for incremental

encoder {xe "Incremental

encoder"}

Assignment for encoder option,

SK XU1-ENC

Assignment for PosiCon option,

SK XU1-POS

15V supply

brown / green

X11.1.42 VO +15V

X10.2.42 VO +15V

0V GND

white / green

X11.1.40 GND /0V

X10.4.40 GND /0V

Track A

brown

X11.2.51 ENC1 A+

X10.4.51 ENC1 A+

Track A inverse

green

X11.2.52 ENC1 A-

X10.4.52 ENC1 A-

Track B

grey

X11.2.53 ENC1 B+

X10.4.53 ENC1 B+

Track B inverse

pink

X11.2.54 ENC1 B-

X10.4.54 ENC1 B-

Track 0

red

--

X10.4.55 ENC1 N+

Track 0 inverse

black

--

X10.4.56 ENC1 N-

Cable shield

connected to a large area of the frequency inverter housing or shielding angle

NOTE:

If there are deviations from the standard equipment (Type 5820.0H40, 10-30V encoder, TTL/RS422)

for the motors, please note the accompanying data sheet or consult your supplier.

RECOMMENDATION: For greater operating safety, in particular with long connection cables, we recommend the use of a

higher power supply (15V/24V) and an incremental encoder for 10-30V power supply. The signal level

must remain at 5V TTL.

ATTENTION:

The rotation field of the incremental encoder must correspond to that of the motor. Therefore,

depending on the rotation direction of the encoder to the motor (possibly reversed), a negative sign

number must be set in parameter P301.