2 controlbox – NORD Drivesystems BU0700 User Manual

Page 33

3.1 Technology unit

BU 0700 GB-1411

Subject to technical alterations

33

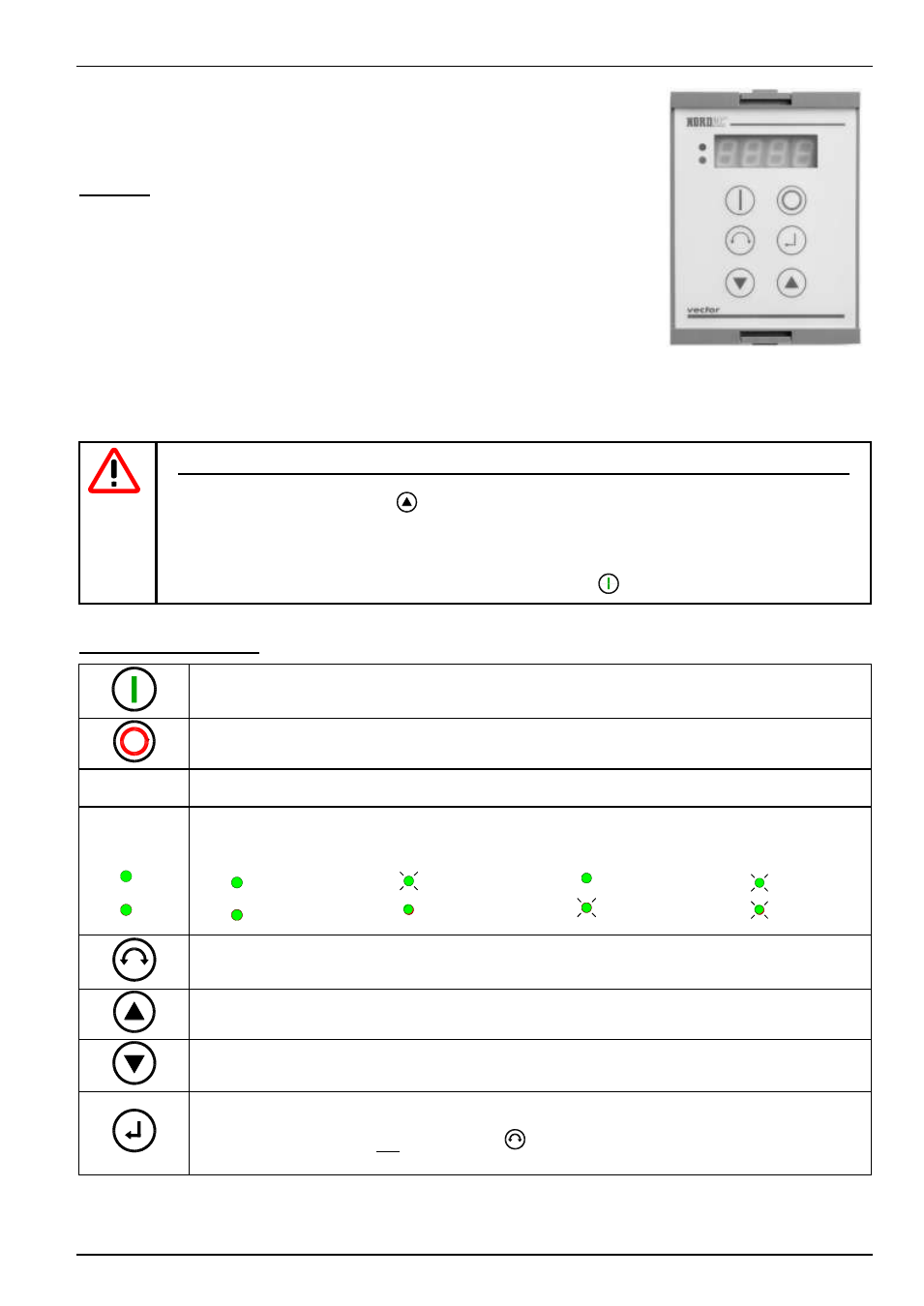

3.1.2 ControlBox

(SK TU1-CTR, Option)

This option is used for the parameterisation and control of the frequency inverter.

Features

4-figure, 7 segment LED display

Direct control of a frequency inverter

Display of the active parameter set.

Storage of a complete frequency inverter parameter set (P550)

After mounting of the ControlBox and the switching on of the mains supply, horizontal

dashes are displayed in the 4 figures of the 7 segment display. This display shows the

operational readiness of the frequency inverter.

If the inverter is switched to enable, the display changes automatically to the operating value selected in parameter >Selection

Display value< P001(default setting = actual frequency).

The actual parameter set is shown by the 2 LEDs next to the display on the left in binary code.

NOTE

The digital frequency setpoint is factory set to 0Hz. To check whether the motor is working, a frequency

setpoint must be entered with the

key or a jog frequency via the respective parameter >Jog

frequency< (P113).

Settings should only be implemented by qualified personnel, strictly in accordance with the warning and

safety information.

ATTENTION : The motor may start immediately after pressing the

START key!

ControlBox functions:

Press to switch on the frequency inverter. The frequency inverter is now enabled with the set jog frequency

(P113). A preset minimum frequency (P104) may at least be provided. Parameter >Interface< P509 must =

0.

Press to switch off the frequency inverter. The output frequency is reduced to the absolute minimum

frequency (P505) and the frequency inverter shuts down at the output side.

7-segment

LED display

Shows the current operating value set during operation (selection in P001) or an error code. During

parameterisation, the parameter numbers or the parameter values are shown.

LEDs

1

2

The LEDs indicate the actual operating parameter set in the operating display (P000) and the actual

parameter set being parameterised during parameterisation. Tin this case the display is coded in binary

form.

1

2

= P1

2

1

= P2

1

2

= P3

2

1

= P4

The motor rotation direction changes when this key is pressed. "Rotation to the left" is indicated by a minus

sign. Attention! Take care when operating pumps. screw conveyors, ventilators, etc. Block the key with

parameter P540.

Press the key to INCREASE the frequency. During parameterisation, the parameter number or parameter

value is increased

Press the key to REDUCE the frequency. During parameterisation, the parameter number or parameter

value is reduced.

Press "ENTER" to store an altered parameter value, or to switch between parameter number or parameter

value.

NOTE: If a changed value is not to be stored, the

key can be used to exit the parameter without storing

the change.