Dwyer PSX2 User Manual

Page 157

148

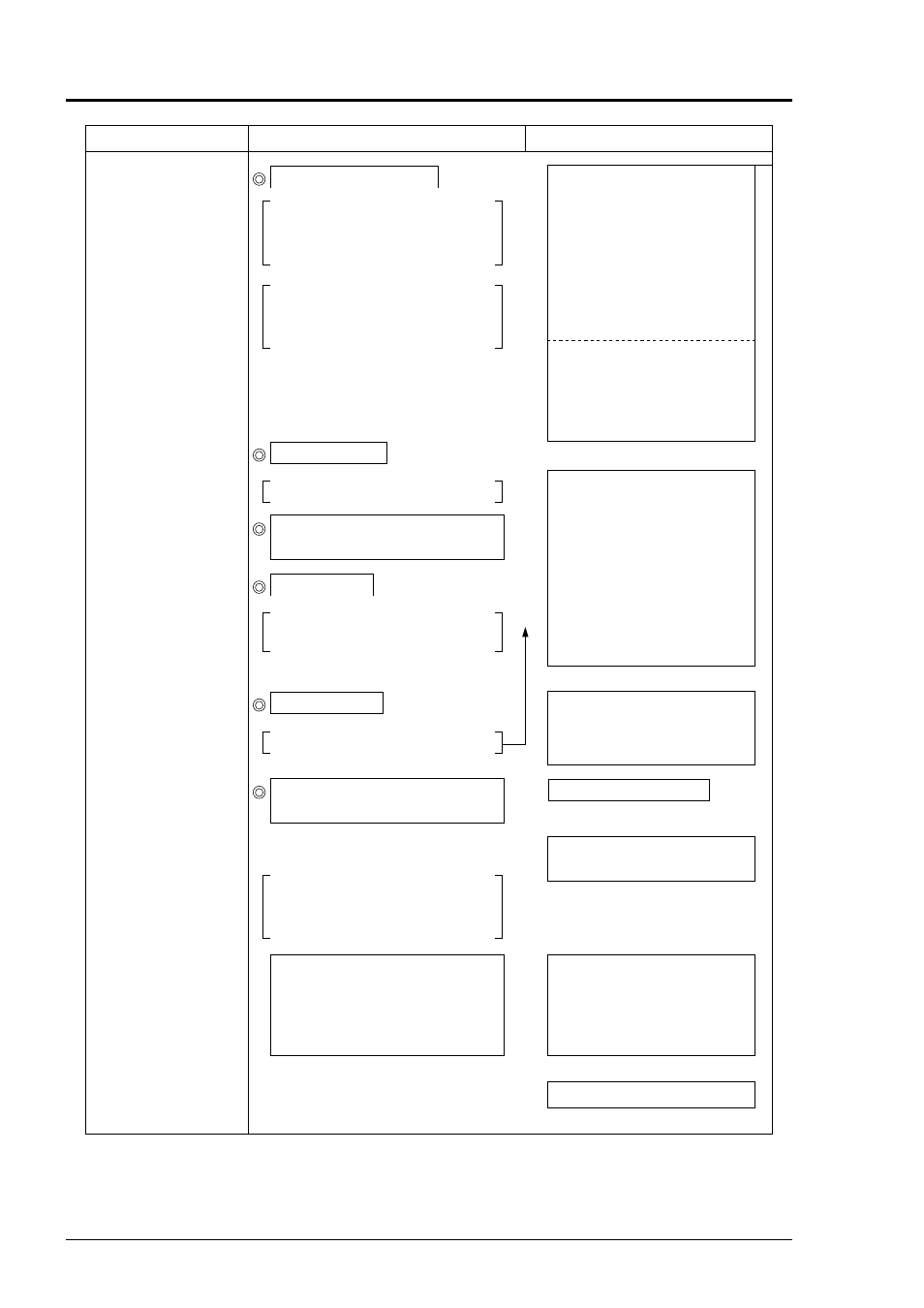

State

Cause

Remedy

Air bubbles have entered.

In case measurement is normal

with water fl ow stopped, entrance

of air bubbles is the cause of this

error.

When the sensor is mounted just

after a valve, cavitation will occur

to cause the same effect as

entrance of air bubbles.

Ö

Eliminate entrance of air

bubbles.

• Raise the level of pump well.

• Confi rm the shaft seal of

pump.

• Retighten the fl ange of nega-

tive pressure piping.

• Prevent fl uid from rushing

into pump well.

Move the sensor to the loca-

tion where air bubbles have not

entered.

• To the inlet side of pump

• To the upstream side of valve

Turbidity is high.

Turbidity is higher than those of

sewage and return sludge.

Ö

• Change the sensor mounting

method from V to Z.

• Move the sensor to the loca-

tion on the same line, where

the outer diameter of pipe is

smaller.

• Move to a different place or

different pipe.

• Raise the voltage for trans-

mission (refer to p.21).

Because of an old pipe, scale has

stuck to the inside.

Ö

Lining is thick.

Because of mortar lining or the

like, thickness is a few ten mm or

more.

Ц

Ш

Lining is peeled.

Try measurement with the

optional large size sensor.

Ö

Contact Manufacturer.

There is a gap between lining and

piping.

Sensor is mounted at a bent pipe or

tapered pipe.

Ö

Mount to a straight pipe.

3. Infl uence by external noise

• There is a radio broadcasting sta-

tion in the vicinity.

• Measurement has been conducted

near heavy traffi c.

Ö

• Minimize the cable between

main unit and sensors.

• Sensor mounting is incomplete.

• Mounting dimension is

improper.

• Sensor is not in contact with

pipe.

Ö

Mount the sensors in parallel

with the pipe following the cor-

rect mounting dimension.

Bring the sensor in close con-

tact with the pipe.

4. Hardware error

Ö

Contact Manufacturer.

Bulletin F-9-PUX2