IAI America ERC User Manual

Page 63

43

3.8 Controlling

Multiple

Axes via Serial Communication

The following operations become possible if multiple axes are controlled:

[1]

Executing movement operations or parameter edit to all axes by connecting teaching pendant or PC via

SIO converter.

[2]

Performing operations via serial communication with the PLC’s communication module as a host by way of

a SIO converter.

3.8.1 Basic

Specifications

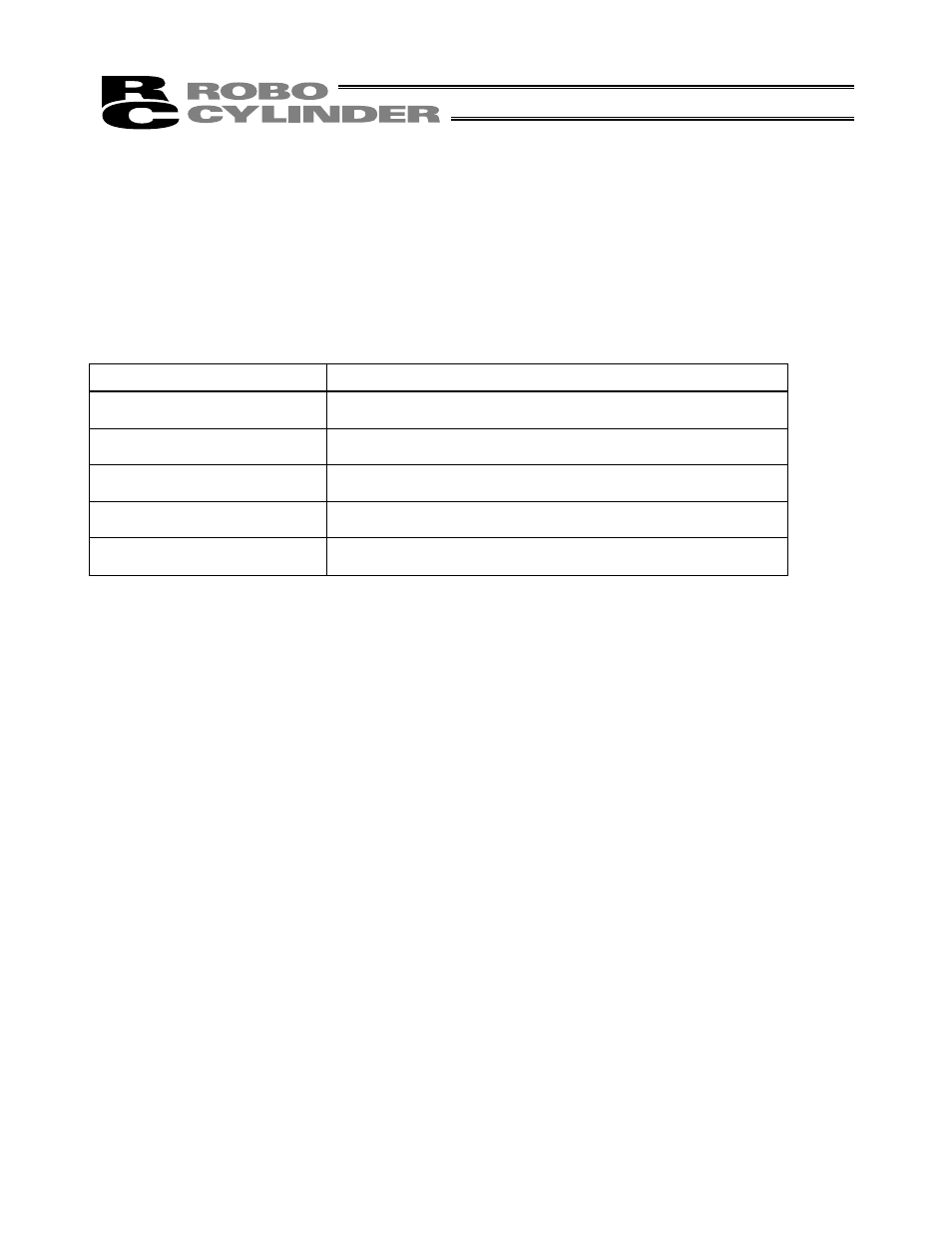

Specification item Description

Communication format

RS485

Transmission speed

115200 bps

(9600 bps, 19200 bps or 38400 bps may also be selected)

Maximum number of units that

can be connected

16 axes

Maximum cable length

100 m or less

Terminal resistor

120

(built into the SIO converter/insulated PIO terminal block);

required if the cable length is 10 m or more.

3.8.2 Address

Assignment

In a linked configuration where multiple axes are connected via serial communication, the host (teaching

pendant, PC or communication module) assigns an address to each axis in order to recognize the corresponding

actuator.

Assign addresses in the setting screen of the teaching pendant or PC.

Overview of operation on the PC

[1] Open the main window

[2] Click Setup (S) [3] Bring the cursor to Controller Setup (C) [4] Bring

the cursor to Assign Address (N) and click the mouse

[5] Enter an appropriate number in the

address table.

Overview of operation on the teaching pendant RCA-T

[1] Open the User Adjustment screen

[2] Use the key to bring the cursor to Address No. [3] Enter

an appropriate address and press the ENTER key

[4] Enter “2” under Adjustment No. and press the

ENTER key

[5] Restart the actuator.

Overview of operation on the simple teaching pendant RCA-E

[1] Open the User Adjustment screen

[2] Press the ENTER key to open the screen showing Address No.

[3] Enter an appropriate address and press the ENTER key [4] Enter “2” under Adjustment No.

and press the ENTER key

[5] Restart the actuator.

Overview of operation on the jog teacher RCB-J

[1] Press the ON/OFF and RUN keys together to turn on the power

[2] Press the – key to open the

screen showing Axis No.

[3] Use the + and – keys to set an appropriate address [4] Press the SET

key

[5] Restart the actuator.

Refer to the operation manual for the teaching pendant or PC software for the specific operating procedure.

In the actual process of assigning addresses, the teaching pendant or PC and the target actuator must have a

one-on-one link. Therefore, disconnect the communication cables (SGA/SGB) from other axes to tentatively

provide a condition where not more than one axis is connected.