3 approved media and ribbon – Datamax-O'Neil H-Class Operator’s Manual User Manual

Page 140

130

H-Class

Media (continued)

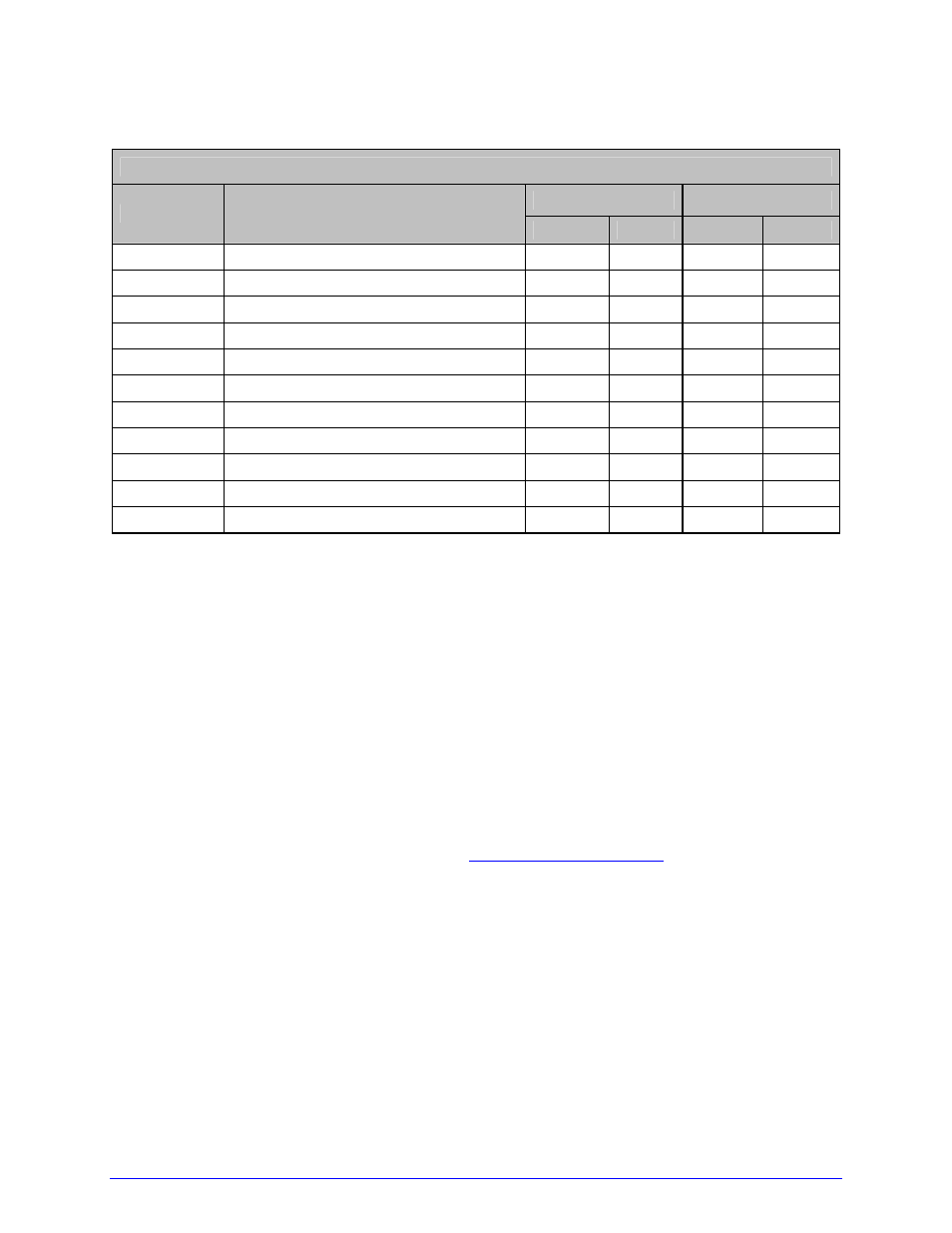

H-8308X Media Dimensional Requirements

[1]

Minimum

Maximum

Designator

Description

inches

mm

inches

mm

A Label

width

3.00 76 9 228

B Liner

width

3.00 76 9 228

C

Gap (or notch) between labels

[3]

.08 2

– –

D Label

length

[3]

.25

6

–

–

E Media

thickness

.0025

.06 .01 .25

F Notch

opening

width

.08 2 – –

G

Media edge to sensor aperture

.20

5

2.25

70

H Reflective

mark

width

[2]

.47

12

9

228

I

Distance between reflective marks

[3]

.25 6

– –

J Reflective

mark

length

[3]

.08

2

–

–

K

Label repeat distance

[3]

.33

8

–

–

[1]

Units of measure are referenced by the direction of label feed.

[2]

The reflective (black) mark must be carbon based, placed on the backside of the stock, and the

reflectance shall be less than 10% at wavelengths of 950 and 640 nm.

[3]

The maximum allowable length of the combined label and gap (or mark) measurement cannot

exceed 99.99 inches.

7.3 Approved Media and Ribbon

Media (and ribbon for thermal transfer) is an important determinant in the throughput,

quality, and performance of the printed product. The following overview is an introduction to

the different types of material that can be used in the printer. For complete information and

advice regarding a specific application, consult a qualified media specialist or a Datamax-

O’Neil Media Representative. Also available is an informative white paper, A Brief

Introduction to Media, which can be found at

www.datamax-oneil.com

Direct Thermal

Consider three important factors when selecting direct thermal stock:

•

The abrasive qualities of the material that covers the thermal reactive layer of the

paper;

•

The amount of heat required to start the chemical reaction; and,

•

The ability of the media to control that chemical reaction.