Datamax-O'Neil H-Class Operator’s Manual User Manual

Page 103

H-Class

93

•

Isopropyl alcohol

•

Soapy water/mild detergent

•

Cotton swabs

•

Compressed air

•

Clean, lint-free cloth

•

Printhead Cleaning Cards or Printhead Cleaning Film

•

Lens tissue

•

Vacuum Cleaner

•

Soft-bristle brush

Schedule

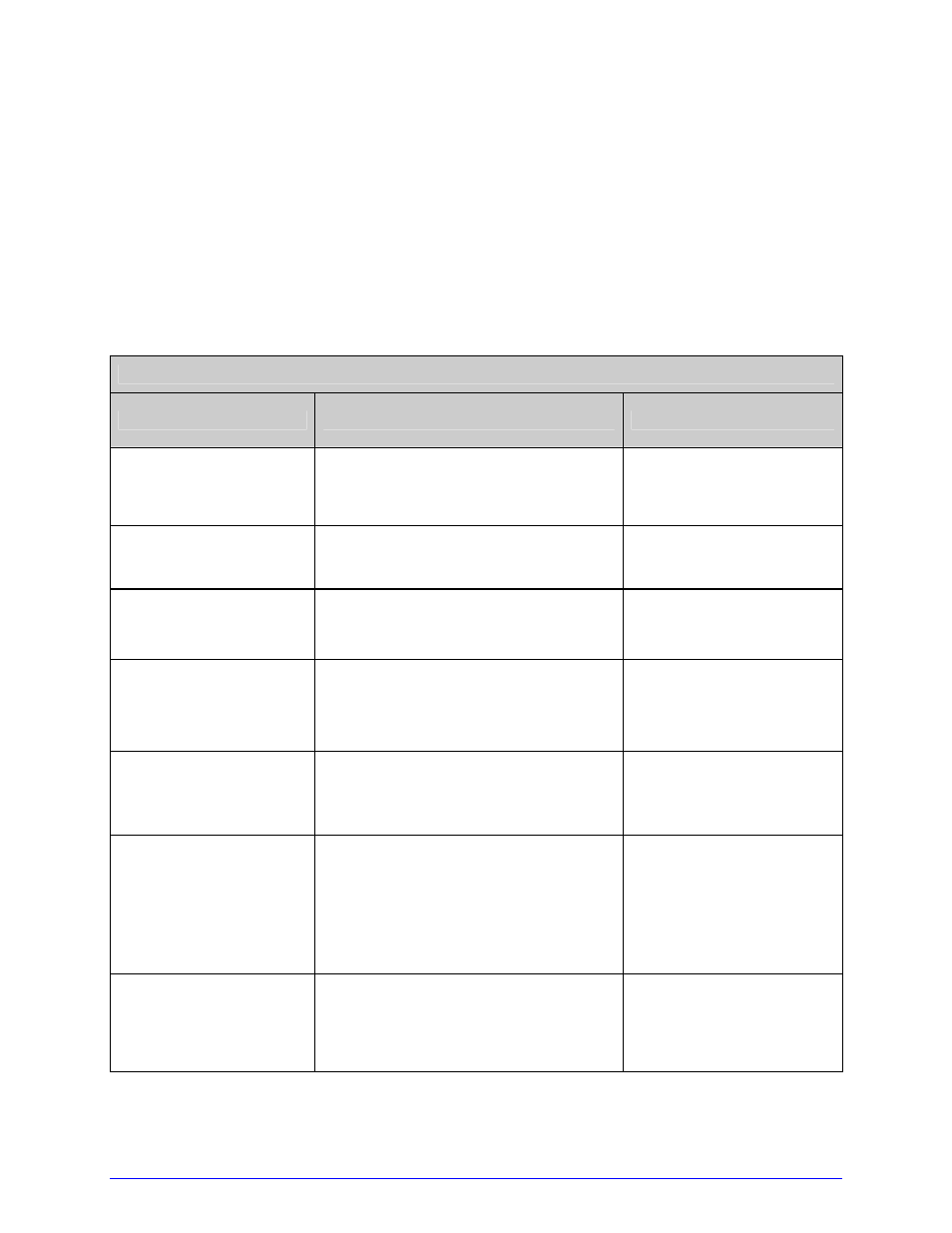

The following table details the recommended cleaning schedules:

Recommended Cleaning Schedule*

Component / Area

Cleaning Interval**

Supplies / Method

Exterior Surfaces

As needed, based on a weekly visual

inspection.

Mild detergent applied

with a dampened cloth;

see Section 5.5.7.

Fan Filter

(tall models only)

As needed, based on a weekly visual

inspection.

Vacuum; see Section

5.5.2.

Interior Compartment As needed, based on a weekly visual

inspection.

Compressed air or a soft

brush; see Section 5.5.3.

Media Sensing

Components

As needed, based on a weekly visual

inspection.

Compressed air, soft

brush, lens tissue and /

or isopropyl alcohol; see

Section 5.5.4.

Platen and Assist

Rollers

After each roll of media or ribbon;

sooner if needed.

Cotton swab or a cloth

dampened with isopropyl

alcohol; see Section

5.5.5.

Printhead

Varies according to the media type:

•

Thermal transfer media – after

each roll of ribbon.

•

Direct thermal media – after

each roll of media, or as needed.

Isopropyl alcohol, and if

necessary Cleaning Cards

or Cleaning Film; see

Section 5.5.1.

Ribbon Path

Components

(equipped models only)

As needed, based on a weekly visual

inspection.

Cotton swab or a cloth

dampened with isopropyl

alcohol; see Section

5.5.6.

*For optional equipment, refer to the documentation that accompanied the item(s).

**Whichever interval comes first.