Install front weldments, Install slide gates, Install front weldments install slide gates – Great Plains YP625PD Predelivery Manual User Manual

Page 63

Great Plains Manufacturing, Inc.

Planter Assembly

59

07/05/2011

401-754Q

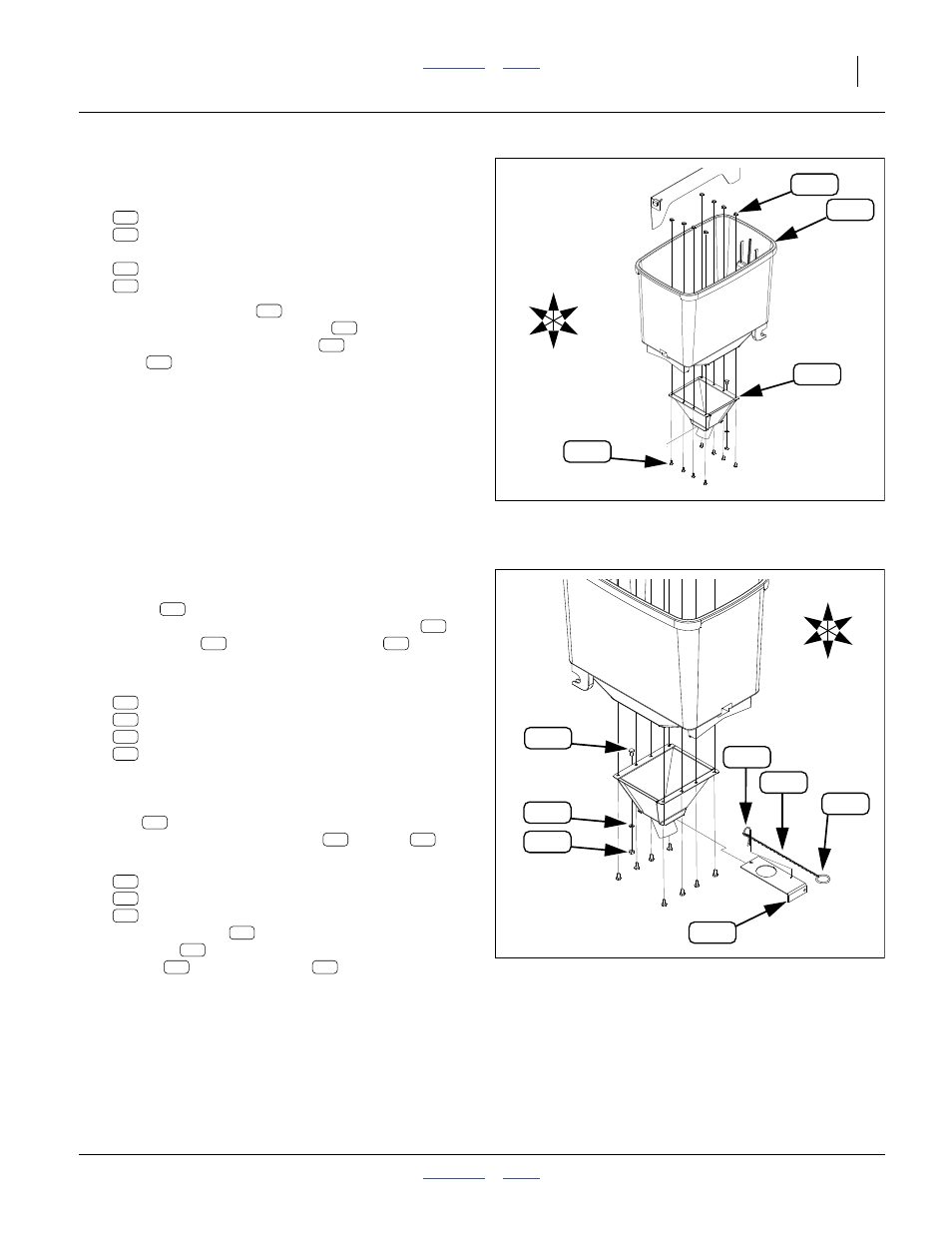

Install Front Weldments

Refer to Figure 121

263. Select one each:

817-268C 96 CHEMICAL HOPPER

403-468H SEED HOPPER DSCHRG WELD FRONT

and eight sets:

802-283C HHCS 1/4-20X1/2 GR2

803-230C NUT HEX FLANGE 1/4-20 PLT

264. Orient the weldment

with the exit tube angled

toward the rear. Insert the bolts

from below the

weldment and into the hopper

. Secure with lock

nuts

.

Null4:

Install Slide Gates

Refer to Figure 122

Slide gates

are installed from the rear, with the short

break (handle) down. They are captured by a bolt

at

the front. A chain

with removable cotter

is used

to hold the gate in the open position.

265. Select one set:

403-429D SLIDE GATE

802-283C HHCS 1/4-20X1/2 GR2

804-006C WASHER LOCK SPRING 1/4 PLT

803-006C NUT HEX 1/4-20 PLT

From the rear of the hopper assembly, with the slide

gate break down, insert the slide gate into the slot at

the top of the weldment tube. From above, insert the

bolt

through the front center hole of the slide

gate. Secure with lock washer

and nut

.

266. Select one set:

502-060D DUST PLUG CHAIN 10

800-051C RING, SPLIT 1-1/4 I.D.

805-031C PIN HAIR COTTER .092 WIRE

Pry the split ring

and rotate it onto one end of

the chain

and through the hole in the slide gate

handle

. Insert the cotter

through the other

end of the chain.

Null4:

Null4:

Figure 121

Install Front Hopper Weldment

Q0085

365

191

302

275

U

D

B

F

R

L

365

191

275

302

191

275

365

302

Null4:

Figure 122

Install Slide Gate and Chain

Q0085

283

187

306

275

U

D

L

R

B

F

322

240

243

187

275

240

322

187

275

306

283

275

306

283

240

243

322

243

240

187

322