Point gauge wheel adjustment, Yoke spring length, Install gauge wheels – Great Plains YP625PD Predelivery Manual User Manual

Page 28: Step 67

24

Great Plains Manufacturing, Inc.

YP625PD/TD/925TD

401-754Q

07/05/2011

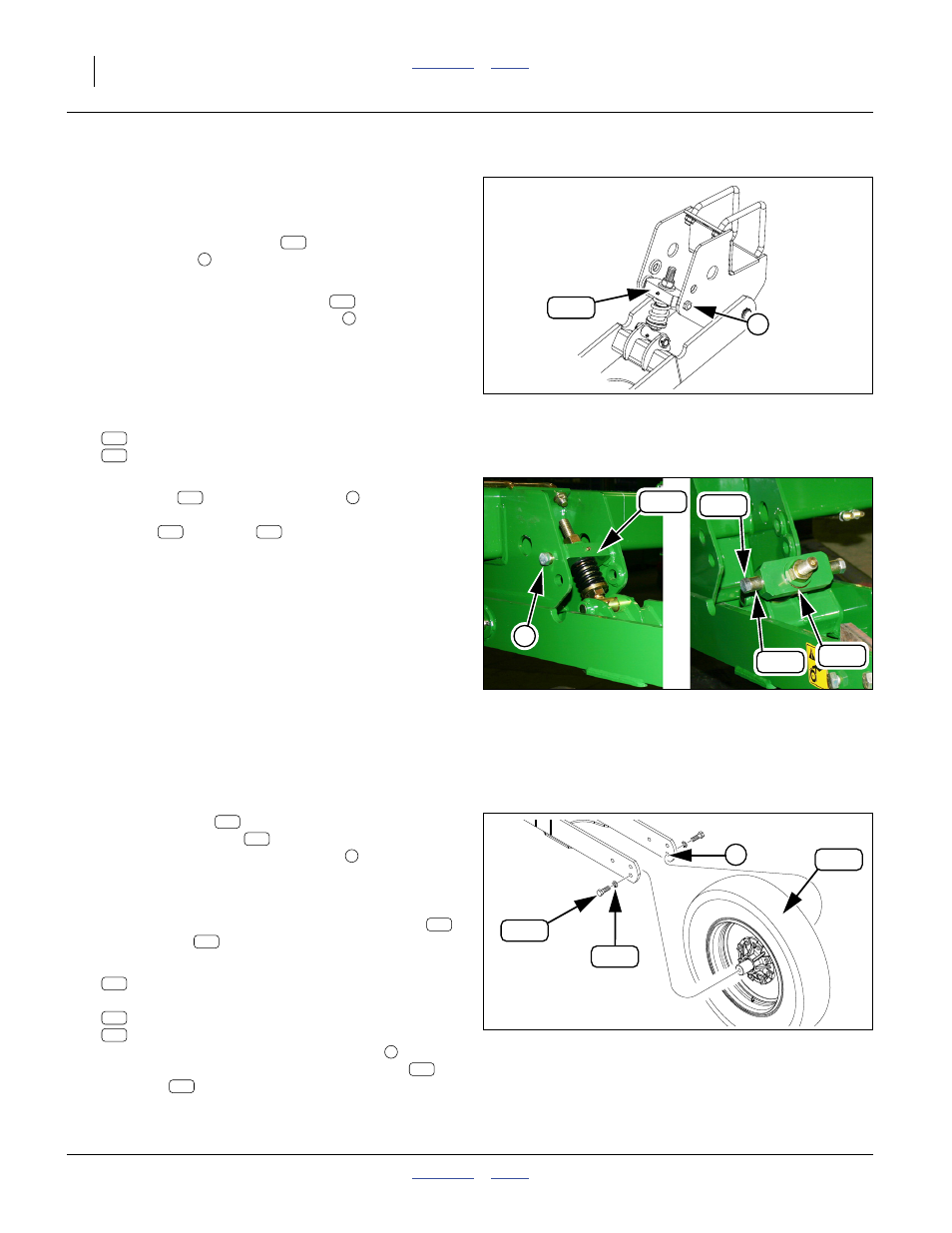

3-Point Gauge Wheel Adjustment

If this is a pull-type planter, continue “Pull-Type Gauge

Wheel Adjustment” on page 23.

Refer to Figure 41 and Figure 42

If all of the gauge wheel yokes

are bolted into the

lower mount holes

For shipment, the gauge wheel yokes

) may be in

flat-ground position (upper mount holes

, as depicted

in left panel of Figure 42) or detached entirely (right

panel of Figure 42).

Note: Prepare to support the gauge wheel arm before

removing bolts.

67. Remove and save two sets:

802-064C HHCS 3/4-10X2 GR5

402-586D SLEEVE SPRING LINK MOUNT

68. Adjust the arm position to allow alignment of the

yoke block

with the lower holes

of the mount.

Secure the yoke in that position with the

sleeves

and bolts

.

Yoke Spring Length

69. Check the length of the spring. See “Gauge Wheel

Adjustments” in the 401-754M or 401-755M

Operator manual.

Null4:

Install Gauge Wheels

Refer to Figure 43

70. If gauge wheels

are already installed, check

where the axle bolts

are installed in the arm

holes. If they are in the lower holes

planting configuration), continue at step 72 on

page 25.

If installed in the upper holes, remove the bolts

and washers

, and continue at step 71.

71. At each gauge wheel arm, select one:

814-385C TIRE & WHL ASY 8R19.5LT

and two sets:

802-065C HHCS 3/4-10X2 1/4 GR5

804-023C WASHER LOCK SPRING 3/4 PLT

Align the wheel axle with the lower holes

gauge wheel arm. Secure with lock washers

and bolts

.

Null4:

Null4:

Figure 41

Yoke in Field Position

31942

1

169

169

169

2

261

180

Null4:

Figure 42:

Shipment Configurations

Q0029

169

180

261

169

2

169

180

261

Null4:

Figure 43

Gauge Wheel Installation

29994

3

262

314

359

359

261

262

314

359

262

314

3

314

262