Install seed hoppers, Assemble seed hoppers, Hopper orientation – Great Plains YP625PD Predelivery Manual User Manual

Page 62: Discharge weldment identification, Quantities per planter model, Install rear weldments, Ud b f

58

Great Plains Manufacturing, Inc.

YP625PD/TD/925TD

401-754Q

07/05/2011

Install Seed Hoppers

Assemble Seed Hoppers

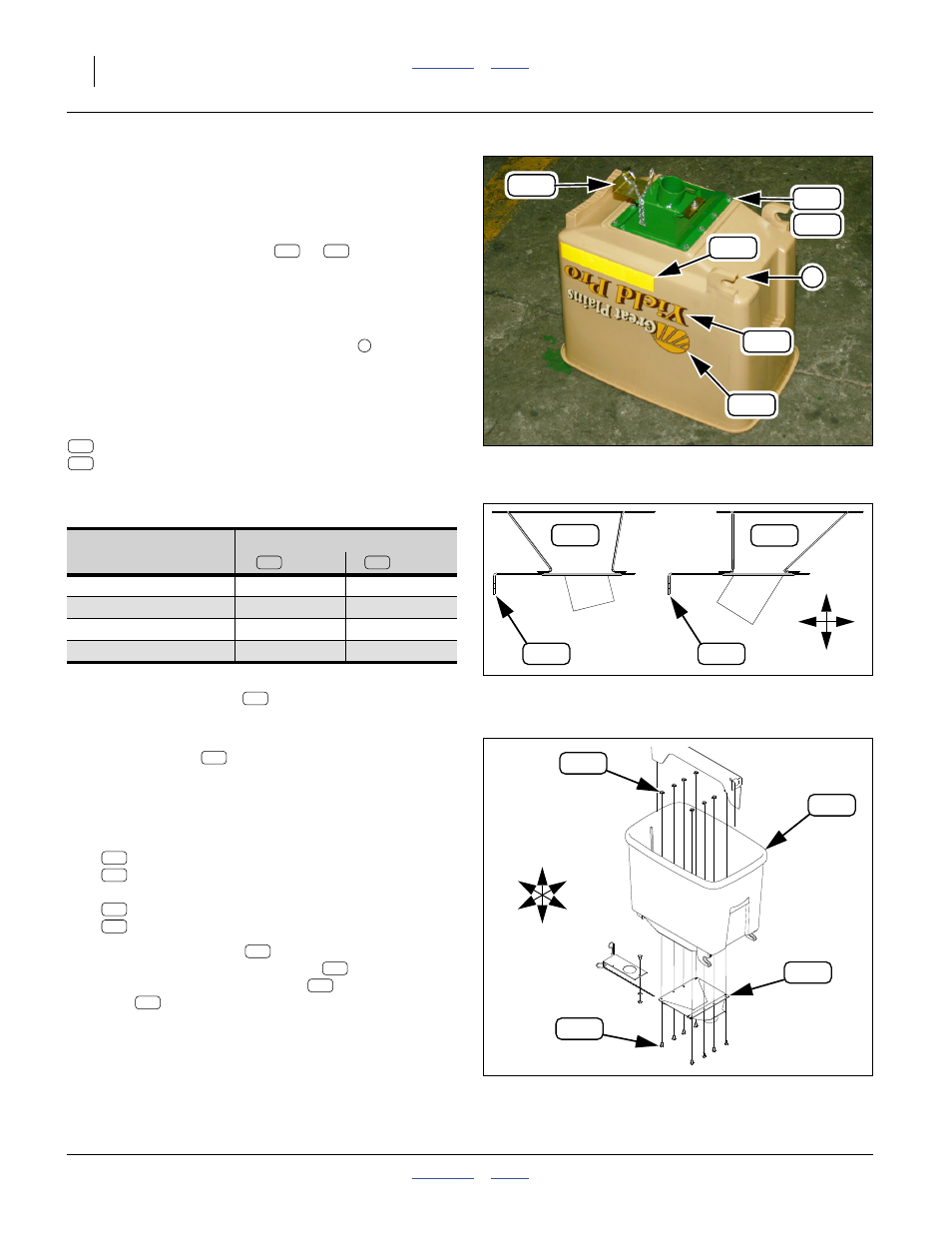

Refer to Figure 118 - depicting a left end hopper with “rear”

style discharge weldment and decals.

If seed discharge weldments (

or

) are already

present on all hoppers, continue at “Mount Seed

Hoppers” on page 60. Any hoppers pre-installed on row

units have the discharge weldments installed.

Hopper Orientation

Seed hoppers install with the lower hooks

toward the

front of the implement.

Discharge Weldment Identification

Refer to Figure 119

Discharge weldments are provided in one or two styles:

403-467H SEED HOPPER DSCHRG WELD REAR

403-468H SEED HOPPER DSCHRG WELD FRONT

depending on the type of row unit:

Quantities Per Planter Model

• Mid-length and long-mount row units use a hopper

with a “rear” weldment

. The discharge tube

angles to the front.

• Short-mount (front) row units use a hopper with a

“front” weldment

. The discharge tube angles to

the back.

Install Rear Weldments

Refer to Figure 118 and Figure 120

261. Select one each:

817-268C 96 CHEMICAL HOPPER

403-467H SEED HOPPER DSCHRG WELD REAR

and eight sets:

802-283C HHCS 1/4-20X1/2 GR2

803-230C NUT HEX FLANGE 1/4-20 PLT

262. Orient the weldment

with the exit tube angled

toward the front. Insert the bolts

from below the

weldment and into the hopper

. Secure with lock

nuts

.

Null4:

Planter

Model

Weldment Quantities

Rear

Front

6

12

6

6

6

12

9

0

Null4:

Figure 118

Assembled End Hopper

Q0082

190

191

392

393

386

187

1

190

191

190

191

Null4:

Figure 119

Discharge Weldment Side View

Q0083

190

191

U

D

B

F

187

187

190

191

190

Null4:

Figure 120

Install Rear Hopper Weldment

Q0084

365

190

302

275

U

D

R

L

F

B

191

365

190

275

302

190

275

365

302