Connect ground drive spring, Install lift assist weldment – Great Plains YP625PD Predelivery Manual User Manual

Page 31

Great Plains Manufacturing, Inc.

Planter Assembly

27

07/05/2011

401-754Q

Connect Ground Drive Spring

Refer to Figure 47

89. At the ground drive arm spring yoke

, remove

and save:

805-064C PIN COTTER 7/64 X 1 LONG

805-127C PIN CLEVIS 1/2 X 1 3/4

90. Align the yoke

with the lug

on the ground

drive arm. Secure with clevis pin

and

cotter

.

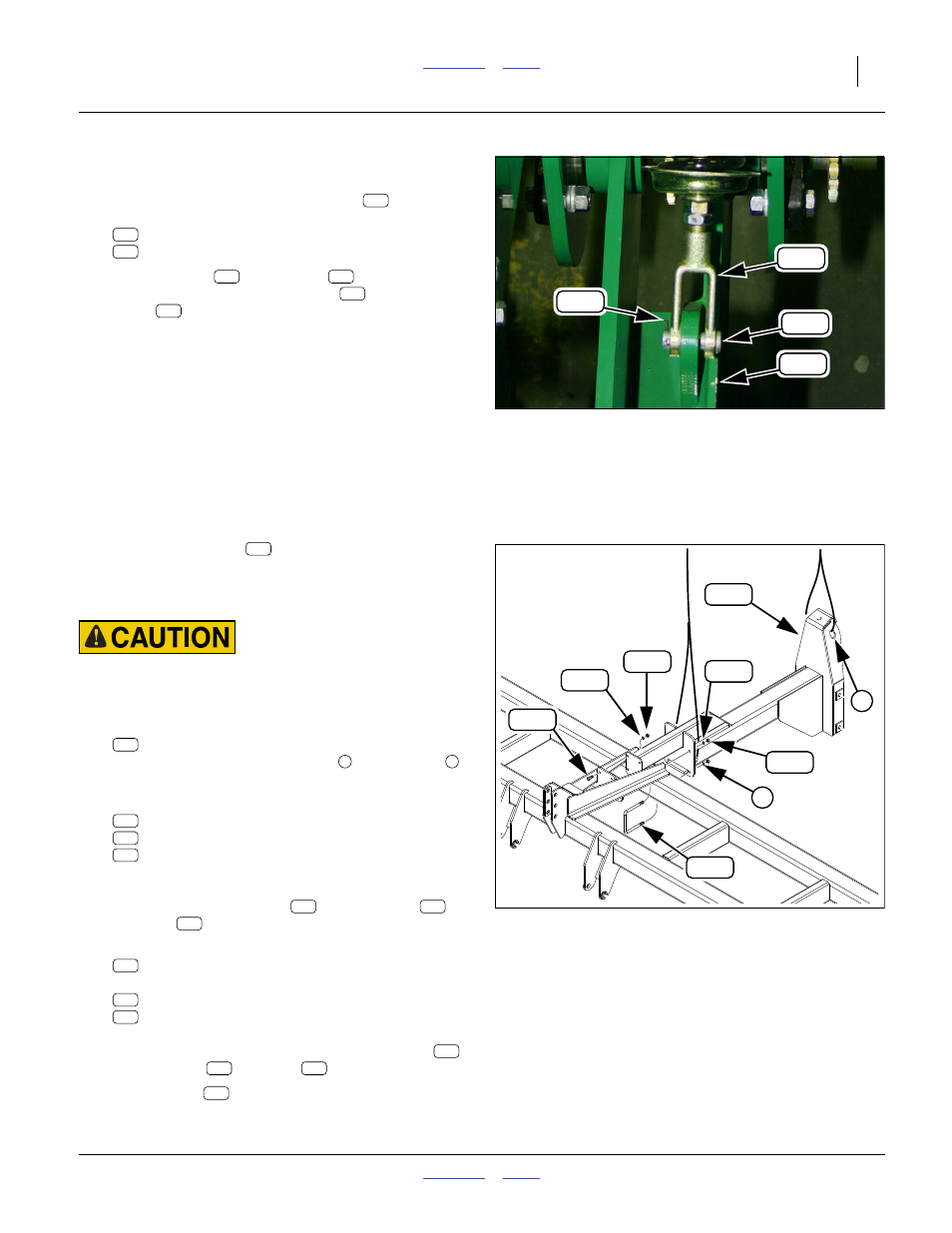

Install Lift Assist Weldment

If the planter is a pull-type model, continue at “Mount

Openers” on page 29.

Refer to Figure 48

The lift-assist weldment

must be installed prior to

installing components that would otherwise interfere with

installation of this weldment. The axle, casters and

hydraulics are not installed until page 33.

Pinch and Crush Hazard:

Use two lift lines. Maneuver the weldment carefully. The

weldment weighs over 300 kg.

91. Select one:

401-751H LIFT ASSIST MOUNT WELD

Secure hoist lines at the forward

and top rear

holes.

92. Select four sets:

802-055C HHCS 5/8-11X2 GR5

804-022C WASHER LOCK SPRING 5/8 PLT

803-021C NUT HEX 5/8-11 PLT

Bring the forward plate of the lift-assist weldment

into contact with the mid plate of the main frame.

Loosely secure with bolts

, lock washers

and nuts

.

93. Select two:

806-050C U-BOLT 3/4-10 X 7 X 8 1/2

and four sets:

804-023C WASHER LOCK SPRING 3/4 PLT

803-027C NUT HEX 3/4-10 PLT

Secure the mid plate of the lift-assist weldment to

the rear tool bar of the main frame with U-bolts

,

lock washers

and nuts

; Grade 5 torque.

94. Secure bolts

at forward plates.

Null4:

Null4:

Figure 47

Ground Drive Spring

Q0033

330

106

324

170

106

324

330

106

170

330

324

Null4:

Figure 48

Lift-Assist Weldment

32053

7

155

338

291

314

313

287

259

8

155

155

259

313

287

259

313

287

338

314

291

338

314

291

259