Rockwell Automation FlexPak 3000 Power Module Version 4.2 User Manual

Page 191

APPENDIX E

49’1340 e

FlexPak 3000

E-7

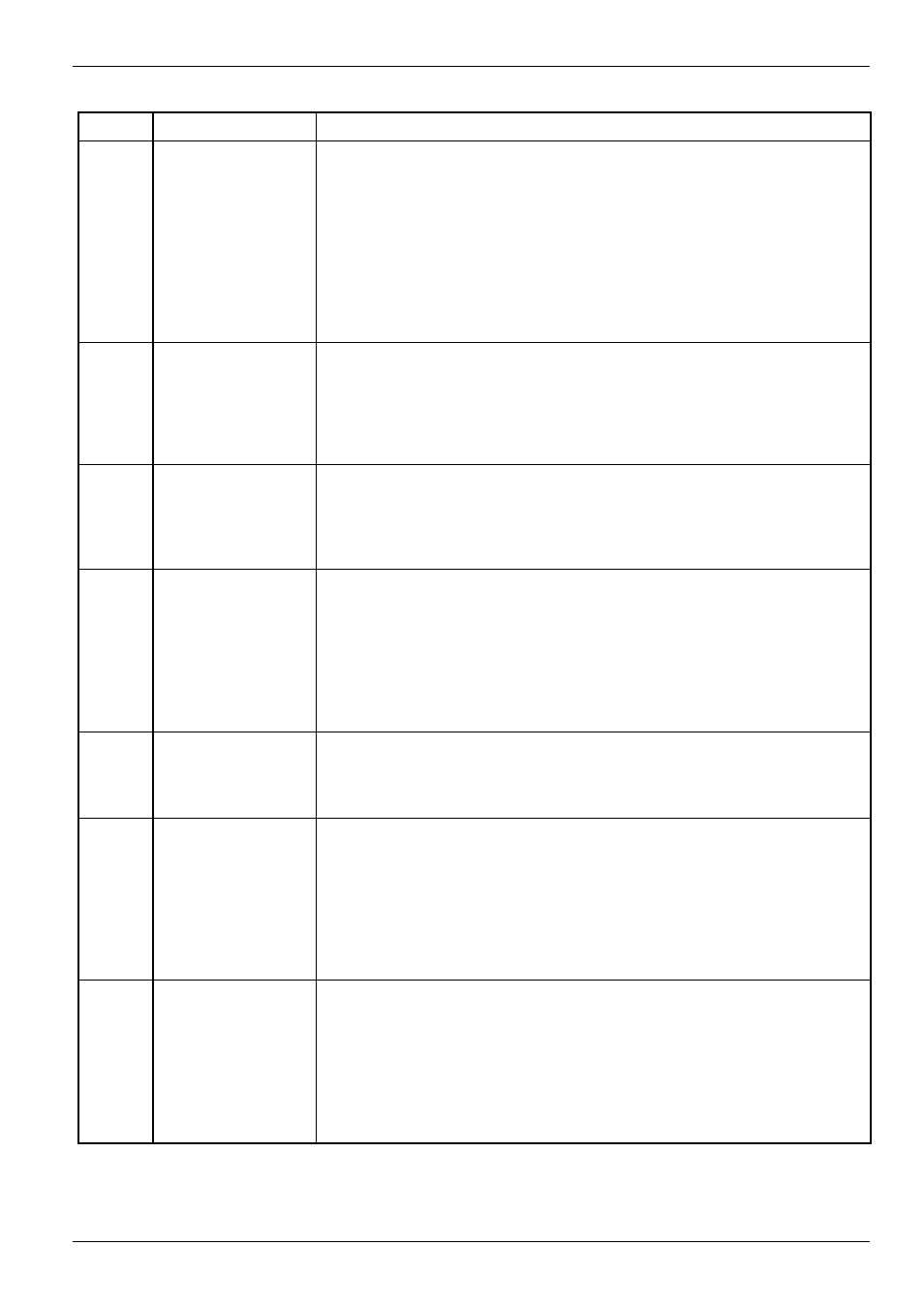

Table E.2 - Alarm Codes

CODE

DISPLAY

DESCRIPTION

A00001 MOTOR BRUSH

WEAR LOW

The motor brush wear detector indicates that the brushes are worn and

require replacement. Only available if

DIG IN 0 SELECT (P.428)

is set to

1 (default). If no motor brush wear detector is used, customer terminal

strip pins 12 & 14 must be jumpered to inhibit this alarm.

Possible causes:

•

Worn motor brushes.

•

Disconnected, loosely connected or damaged motor brush wear

indicator wiring.

•

Motor brush wear indicator failure.

A00002 AC LINE

VOLTAGE LOW

The A-C line voltage fell below 90% of the

NOMINAL AC LINE VOLTS

.

Possible causes:

•

Low AC line voltage.

•

Incorrect value entered for

NOMINAL AC LINE VOLTS (P.307).

•

Blown AC line fuse(s).

A00003 AC LINE

VOLTAGE HIGH

The AC line voltage rose above 115% of

the NOMINAL AC LINE VOLTS.

Possible causes:

•

High A-C line voltage.

•

Incorrect value entered for

NOMINAL AC LINE VOLTS (P.307).

A00004 NETWORK

COMMUNICATION

TIMEOUT

Network Communications is missing or failed to communicate with

master. (

CONTROL SOURCE SELECT = NETWORK

)

Possible causes:

•

NETW CONNECT TYPE

(P.910) was changed from

BASIC

to

FULL

.

•

NETW DROP NUMBER

(P.900) was changed.

•

Network Option cable connections are loose or not connected.

•

Network Option device failed or master communications failed.

A00005

INVERTING FAULT

AVOIDED

The inverting fault

avoidance logic has detected conditions that could

have caused an inverting fault. The drive took action to avoid an actual

inverting fault.

See Parameter P.312 description for more information.

A00030

1)

MAIN CONTACTOR

DID NOT OPEN

The main contactor (K1M) did not open following a stop.

Possible causes:

•

Disconnected, loosely connected, or damaged main contactor (K1M)

or Aux. contactor (K1) wiring.

•

Main contactor or Aux. Main contactor failure.

•

Disconnected, loosely connected, or damaged main contactor control

wiring (MCR).

A00031

2)

MAIN CONTACTOR

DID NOT CLOSE

The main contactor (K1M) did not close following a run or jog request.

Possible causes:

•

Disconnected, loosely connected, or damaged main contactor (K1M)

or Aux. contactor (K1) wiring.

•

Main contactor or Aux. Main contactor failure.

•

Disconnected, loosely connected, or damaged main contactor control

wiring (MCR).

1) When after stop command, the auxiliary contactor does not indicate that the main contactor opened,

this alarm indication is time delayed: 1000 msec fixed on SW-V4.2 (400 msec on SW-V4.1).

2) When after start command, the auxiliary contactor does not indicate that the main contactor closed,

this alarm indication is time delayed: 1000 msec fixed on SW-V4.2 (400 msec on SW-V4.1).