Rockwell Automation FlexPak 3000 Power Module Version 4.2 User Manual

Page 186

APPENDIX E

FlexPak 3000

49’1340 e

E-2

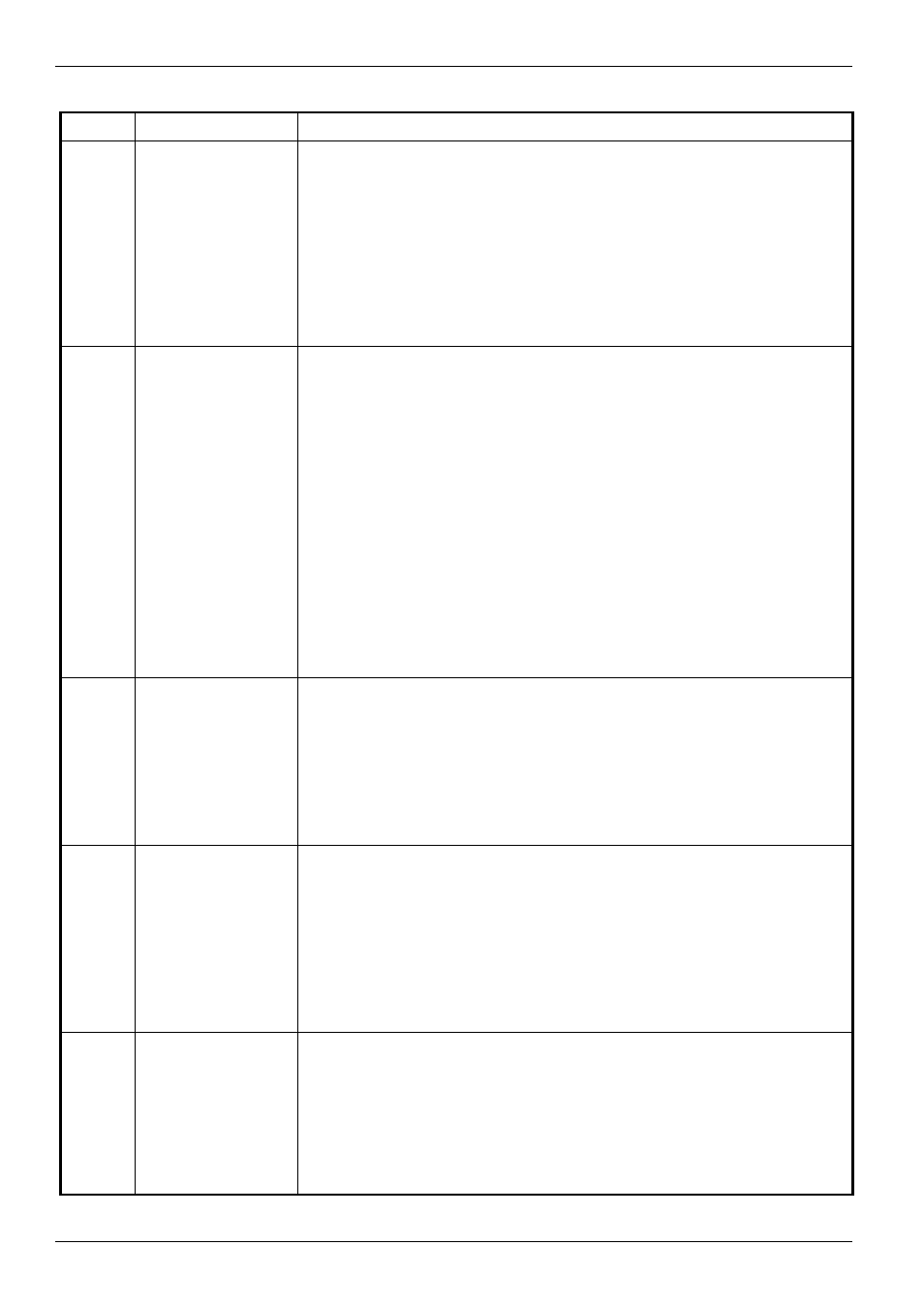

Table E.1 - Fault Codes

CODE

DISPLAY

DESCRIPTION

F00001 IET

(OVERCURRENT)

Armature current instantaneously exceeded 180% of

MAXIMUM

CURRENT

.

Possible causes:

•

Incorrect armature current feedback scaling

(MOTOR RATED ARM

AMPS, MAXIMUM CURRENT, CT TURNS RATIO

and/or J18 not set

properly).

•

One or more thyristors not operating.

•

Improper Current Minor Loop tuning.

•

Motor armature winding damaged.

F00002 TACHOMETER

LOSS

Tachometer feedback signal missing.

Possible causes:

•

Tachometer coupling failure.

•

Disconnected, loosely connected, or damaged tachometer wires.

•

Pulse encoder supply voltage low.

•

Incorrect tachometer polarity.

•

Incorrect analog tachometer scaling.

•

Incorrect pulse encoder configuration.

•

Motor armature winding not connected or open circuit.

•

Blown inverting fault (DC) fuse.

•

Inverting fault breaker tripped.

•

Tachometer failure.

•

Excessive armature voltage at motor speed <5% of TOP SPEED,

Refer to Appendix B, TACH LOSS SCR ANGLE (P608).

F00003 OVERSPEED

Motor speed exceeded the 110% of

TOP SPEED

.

Possible causes:

•

Incorrect tachometer scaling.

•

Blown field supply fuse(s).

•

Improper speed loop tuning.

•

PULSE TACH QUADRATURE

set to ON for a non-regenerative drive.

•

Incorrect pulse encoder wiring.

F00004 FIELD CURRENT

LOSS

The field loss detection circuit does not sense any field current flowing

in the motor shunt field.

Possible causes:

•

Motor field winding not connected or open circuit.

•

Blown field supply fuse(s).

•

Blown AC line fuse(s).

•

Field supply failure.

•

Disconnected, loosely connected or damaged wiring harness.

F00005 SUSTAINED

OVERLOAD

Inverse time overload circuit trip.

Possible causes:

•

Incorrect armature current feedback scaling

(MOTOR RATED ARM

AMPS, MAXIMUM CURRENT, CT TURNS RATIO

and/or J18 not set

properly).

•

Blown field supply fuse(s).

•

Mechanical binding preventing the motor shaft from rotating freely.