Rockwell Automation FlexPak 3000 Power Module Version 4.2 User Manual

Page 190

APPENDIX E

FlexPak 3000

49’1340 e

E-6

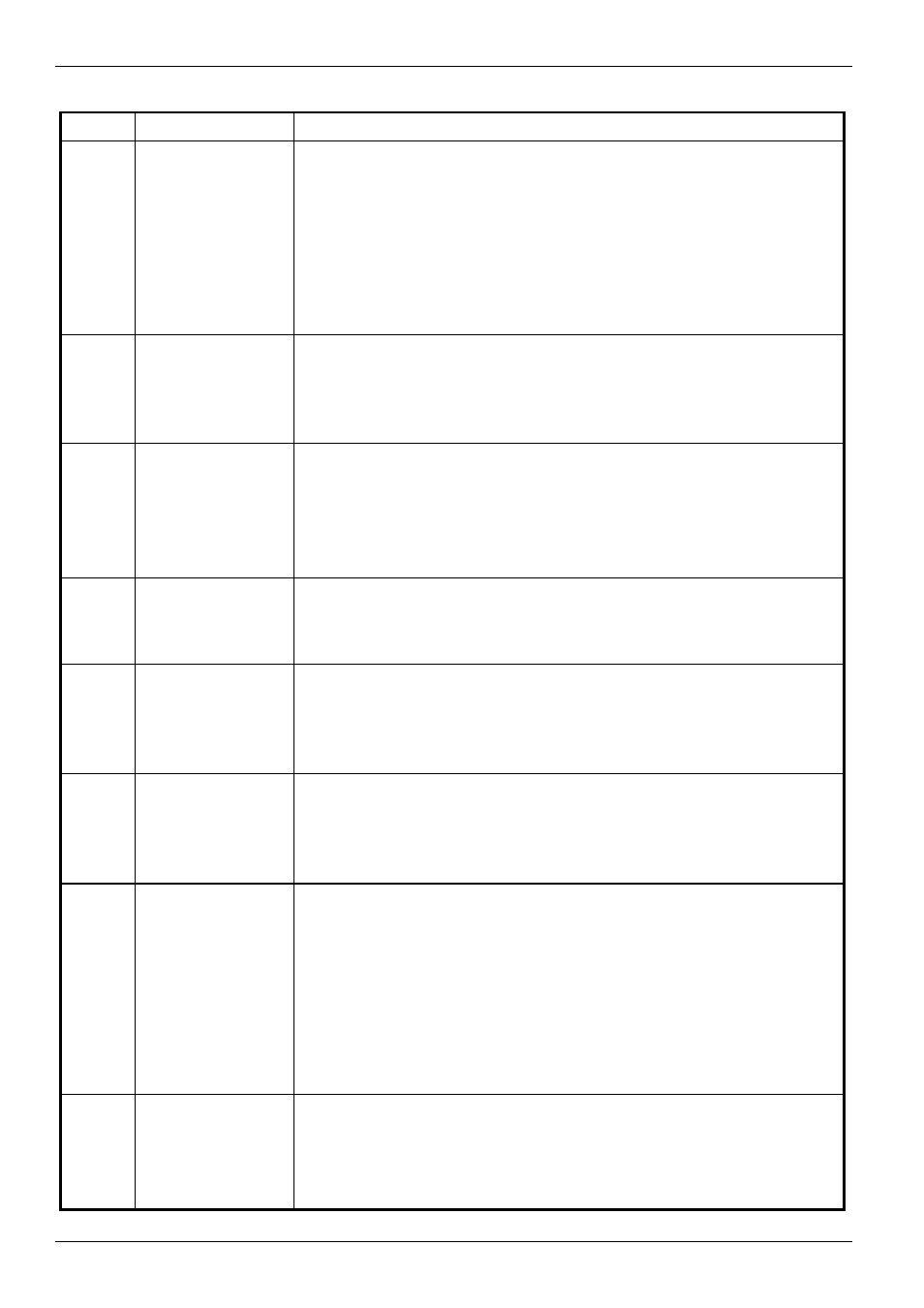

Table E.1 - Fault Codes (Continued)

CODE

DISPLAY

DESCRIPTION

F00700

FACTORY

DEFAULTS

RESTORED

The parameter values stored in retentive memory were determined to

be invalid, factory default values have been restored. All parameter

values (including any factory set parameters) must be re-adjusted

based on your particular application's requirements before the drive is

operated. After all parameters have been set properly, a memory save

must be performed.

Possible causes:

•

Power loss during a prior memory save.

•

New or defective regulator board.

F00701

FAULT LOG

RESTORE FAILURE

The fault log information stored in retentive memory was determined to

be invalid, the fault log has been cleared.

Possible causes:

•

Power loss during a prior fault log save.

•

Defective regulator board.

F00702 KEYPAD REF

RESTORE

FAILURE

The keypad reference value stored in retentive memory was

determined to be invalid, the keypad reference has been set to the

MINIMUM SPEED

value.

Possible causes:

•

Power loss during a prior keypad reference save.

•

Defective regulator board.

F00703 OIM KEY

RESTORE

FAILURE

The OIM key states stored in retentive memory were determined to be

invalid, the

FORWARD/REVERSE

key has been set to

FORWARD

, the

AUTO/MANUAL

key has been set to

MANUAL

.

Possible cause: Defective regulator board.

F00800

INVALID FIELD

INSTALLED

Installed field supply is not supported by the regulator.

Possible causes:

•

Disconnected, loosely connected, or damaged field supply wiring.

•

Regulated field supply failure.

•

Defective regulator board.

F00801

FIELD FEEDBACK

OFFSET TOO HIGH

Regulated field supply feedback offset is too high.

Possible causes:

•

Disconnected, loosely connected, or damaged field supply wiring.

•

Regulated field supply failure.

•

Defective regulator board.

F01000

to

F01999

MICROBUS

FAULT

An error occurred on the Microbus.

Possible causes:

•

Electrical noise due to improper wiring practices or unsuppressed

brake coils, relays, or contactors.

•

Disconnected, loosely connected or damaged Microbus ribbon cable.

•

Defective regulator board.

•

F01000-F01799: Defective Microbus peripheral or defective

Regulator board.

•

F01810-F01816: A Microbus peripheral was found that is not

supported by the regulator software.

F00999

and

F02000

to

F03999

MICRO-

PROCESSOR

HW/SW FAULT

A microprocessor hardware or software fault occurred.

Possible causes:

•

Electrical noise due to improper wiring practices or unsuppressed

brake coils, relays, contactors.

•

Defective regulator board.