5 boom section separation adjustment, 6 hydraulic sub-assembly removal/installation, 1 hydraulic sub-assembly removal – JLG G12-55A AccuPlace Service Manual User Manual

Page 36: Boom section separation adjustment, Hydraulic sub-assembly removal/installation, Hydraulic sub-assembly removal

Boom

3.14

G10-55A & G12-55A AccuPlace

3.5

BOOM SECTION SEPARATION

ADJUSTMENT

1. Park the machine on level ground. Place the

transmission control lever in (N) NEUTRAL, engage

the parking brake switch and raise the boom to a

horizontal (level) position.

2. Extend the boom 4 ft to 5 ft, then fully retract the

boom.

3. Measure the gap between the flat washer at the

extend chain anchor on the top front of the first boom

section and the second boom section. If the gap is

greater that 3/8 in. (9.52 mm), the boom chains will

need to be adjusted.

While doing the chain inspection, check all chain clevis

ends for distortion or cracking and sheaves for bearing

wear or grooving from the chain.

4. If during the inspection, any chain is found to be

damaged or stretched, the chain must be replaced. It

is recommended that when any chain is replaced,

that all the chains and clevises be replaced at the

same time.

Adjust the extend chain as follows:

1. Loosen the lock nut on each of the extend chains.

2. Tighten the adjusting nut on the first boom section

until the gap between the flat washers and boom is

3/8 in. (9,52 mm) maximum. The gap must be equal

on both chains. Torque the lock nut to 100 lb-ft

(135 Nm).

3. Tighten the adjusting nut on the second boom

section until the gap between the washer and boom

is 3/8 in. (9,52 mm) maximum. Torque the lock nut to

100 lb-ft (135 Nm).

4. After adjusting, check to see that the boom sections

and access holes are aligned. If they are not, the

retract chain will need to be adjusted as well.

Adjust the retract chain as follows:

1. Fully retract the boom.

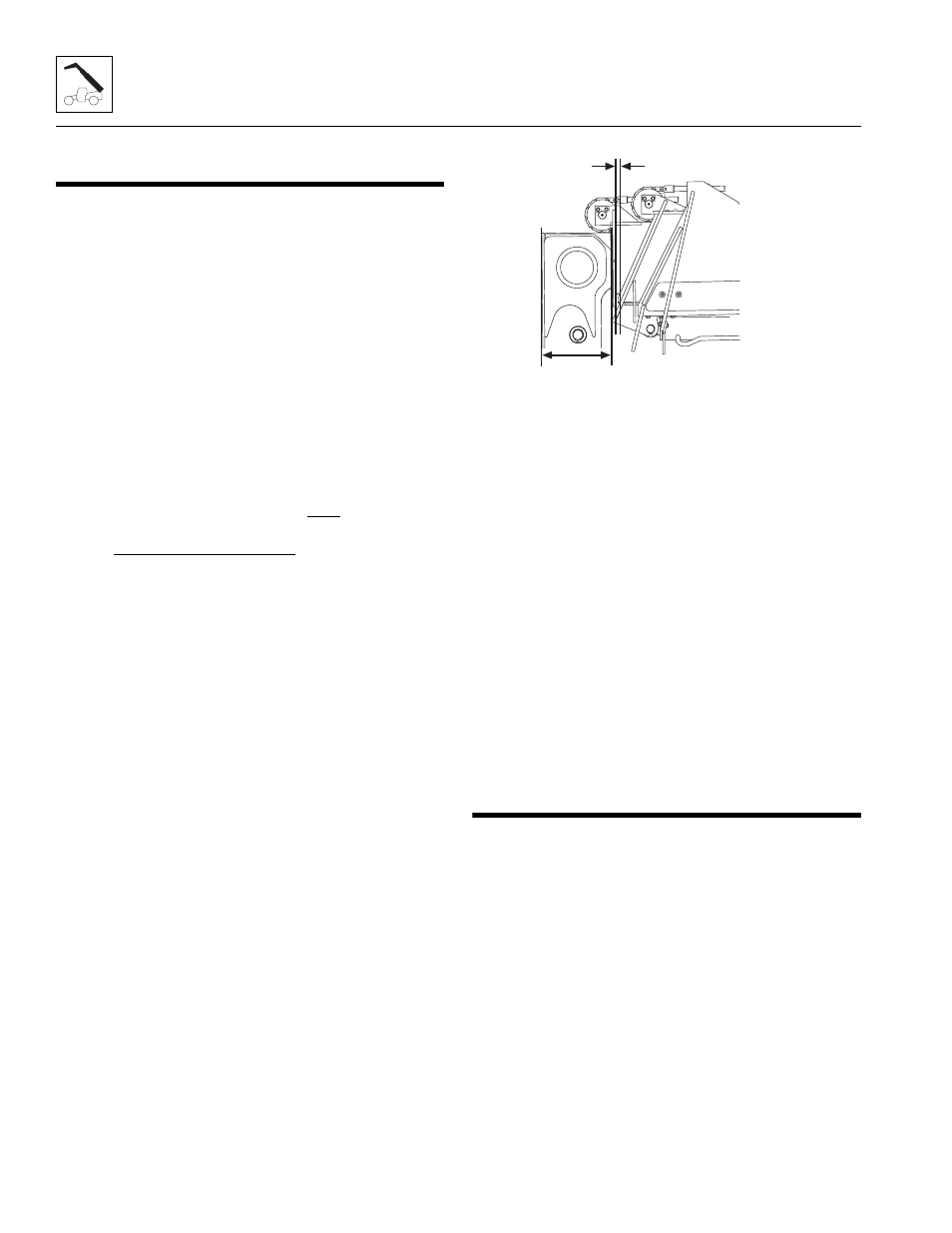

2. Measure the distance between the second boom

section and the third boom section (1). The

dimension should be 0.500 in, + 0.250 in - 0.0 in

(12,7 mm, + 6,75 mm - 0.0 mm).

3. Loosen the retract chain lock nut and adjusting nut

as far as possible.

4. Tighten the retract chain adjusting nut until the

proper distance is obtained and proper access hole

alignment is obtained.

5. Torque the lock nut to 100 lb-ft (135 Nm).

6. Recheck the extend chain adjustments and readjust

if necessary.

7. Measure the distance between the third boom

section and fourth boom section (2). The dimension

should be 18.5 in, + 0.25 in - 0.0 in

(469,9 mm, + 6,75 mm - 0,0 mm)

8. Tighten the retract chain adjusting nut until the

proper distance is obtained and proper access hole

alignment is obtained.

9. Torque the lock nuts to 100 lb-ft (135 Nm).

10. Re-adjust the extend chain as needed.

3.6

HYDRAULIC SUB-ASSEMBLY

REMOVAL/INSTALLATION

The hydraulic sub-assembly is located primarily in the

fourth boom section. It is fastened at the bottom front of

the fourth boom section and at the rear of the third boom

section.

3.6.1

Hydraulic Sub-Assembly Removal

1. Remove any attachment from the quick switch

assembly.

Note: Allow adequate room in front of the machine

when removing and installing the hydraulic sub-

assembly.

MY1320

1

2