8 diagnostic trouble code (dtc) table, Section, 8, “diagnostic trouble code (dtc) table – JLG G12-55A AccuPlace Service Manual User Manual

Page 177: Diagnostic trouble code (dtc) table

9.59

G10-55A & G12-55A AccuPlace

Electrical System

9.15.8

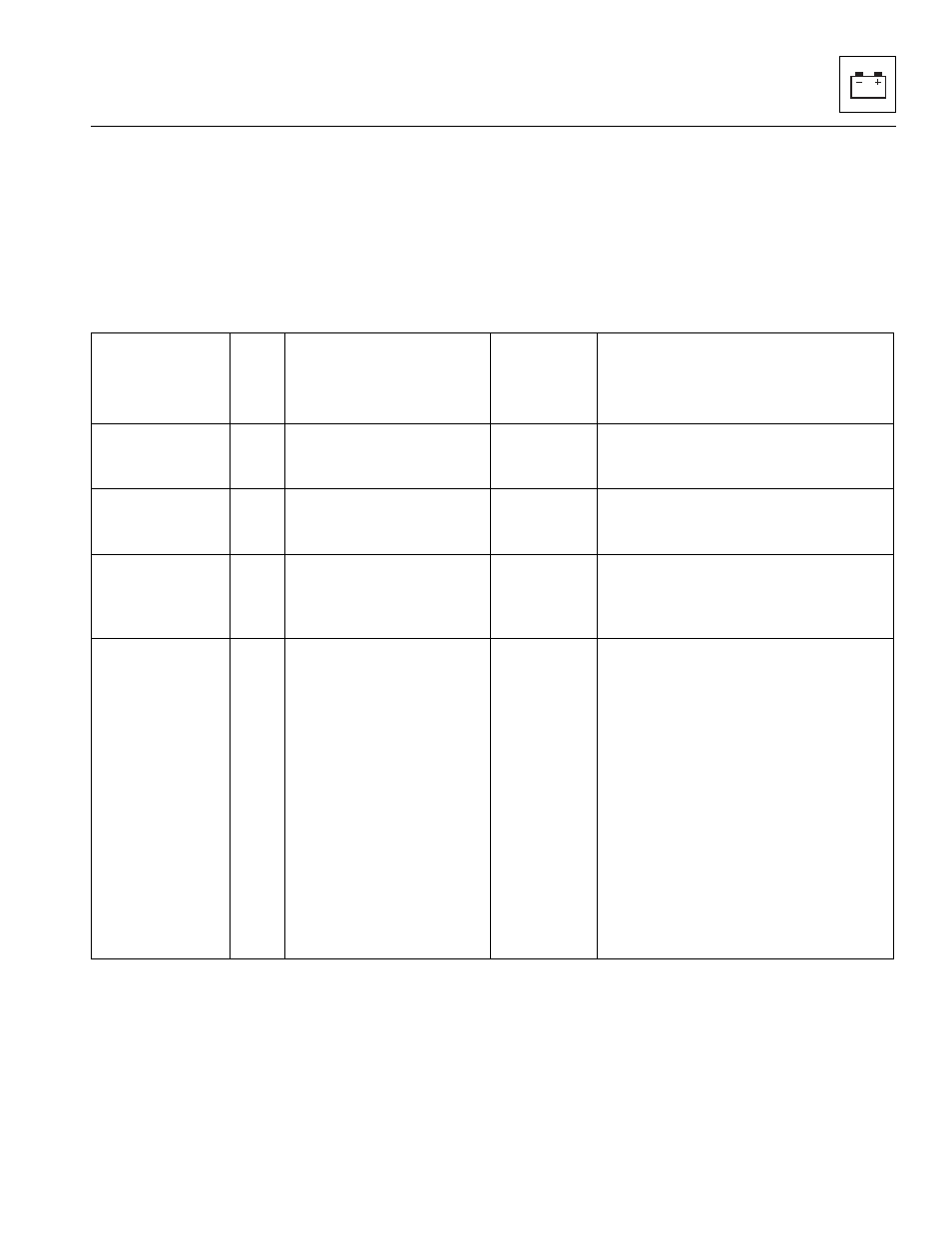

Diagnostic Trouble Code (DTC) Table

Note: The column labeled “Fault Requires AccuPlace

Reset” indicates whether the AccuPlace Mode Fault

Reset button is required to be pushed if a fault occurs

while operating in AccuPlace mode (Y = Yes, N = No). In

addition to pressing the Reset button if in AccuPlace

mode even if not explicitly stated, the conditions under

the “Action” description are required. Motion is permitted

after AccuPlace Fault Reset button is pushed. If

operating in Standard mode and a fault occurs, pushing

AccuPlace Mode Fault Reset button is never required.

Note:

1

All faults disregarded during engine crank except

those annotated.

2

Fault/Check applies during Power Up/System

Initialization period.

Help Message

1

DTC

Fault Condition

(for configurable items,

fault applies only if

configured)

Fault

Requires

AccuPlace

Reset?

Action(s)

EVERYTHING OK

001

None

N

For information only; system fully

functional. Not stored in Fault Log or sent

to 3-N-1 gauge.

ENVELOPE LIMIT

REACHED

0026

AccuPlace function limit has

been reached.

N

Normal condition; for information only.

Not stored in Fault Log or sent to 3-N-1

gauge.

POWER CYCLE

2

211

None

N

Normal operation. Used as a marker to

denote the end of the Fault Log for the

faults logged during the current power

cycle.

JOYSTICK AXES

NOT IN NEUTRAL

AT POWER UP

2

215

Main Joystick X and Y axes

not in neutral during system

startup.

N

Center joystick and normal operation

should resume. If not, check that the X and

Y axis commands = 0% and In-Neutral

under Diagnostics/Main Joystick on the

Analyzer when the joystick is centered.

If the readings display ???, this indicates

that the CAN Bus is not communicating or

Main joystick power is lost.

Check joystick signal and continuity of its

wiring connections. The joystick should

read 120 ohms across CAN2H and

CAN2L when disconnected from the

machine harness. When disconnected

from the joystick, the machine harness

should also have 120ohms between

CAN2H and CAN2L.