4 pump solenoid valve, Pump solenoid valve – JLG G12-55A AccuPlace Service Manual User Manual

Page 146

Electrical System

9.28

G10-55A & G12-55A AccuPlace

place the transmission control lever in

(N) NEUTRAL, engage the park brake and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Disconnect the battery negative (-) cable from the

battery negative (-) terminal.

5. Disconnect the two wiring connectors at the sway

solenoid leads.

6. Remove the nut on the end of the sway coil (3).

7. Remove the sway coil.

8. Remove the sway solenoid (4). (Remove only if the

electrical coil is found to not be faulty; cold

resistance approximately 6 ohm.)

b. Disassembly

DO NOT disassemble the solenoid. The solenoid is not

serviceable. Replace solenoid if found to be defective.

c. Sway Solenoid Valve Installation

Note: ALWAYS replace seals, o-rings, gaskets, etc.,

with new parts to help ensure proper sealing and

operation. Lubricate seals and o-rings with clean

hydraulic oil.

1. If necessary, install the sway solenoid in its original

orientation.

2. Slide the sway coil over the solenoid. Tighten the nut

to secure the solenoid. DO NOT overtighten.

3. Connect the two wiring connectors to the sway coil

leads.

4. Connect the battery negative (-) cable at the battery

negative (-) terminal.

5. Close and secure the engine cover.

9.11.4

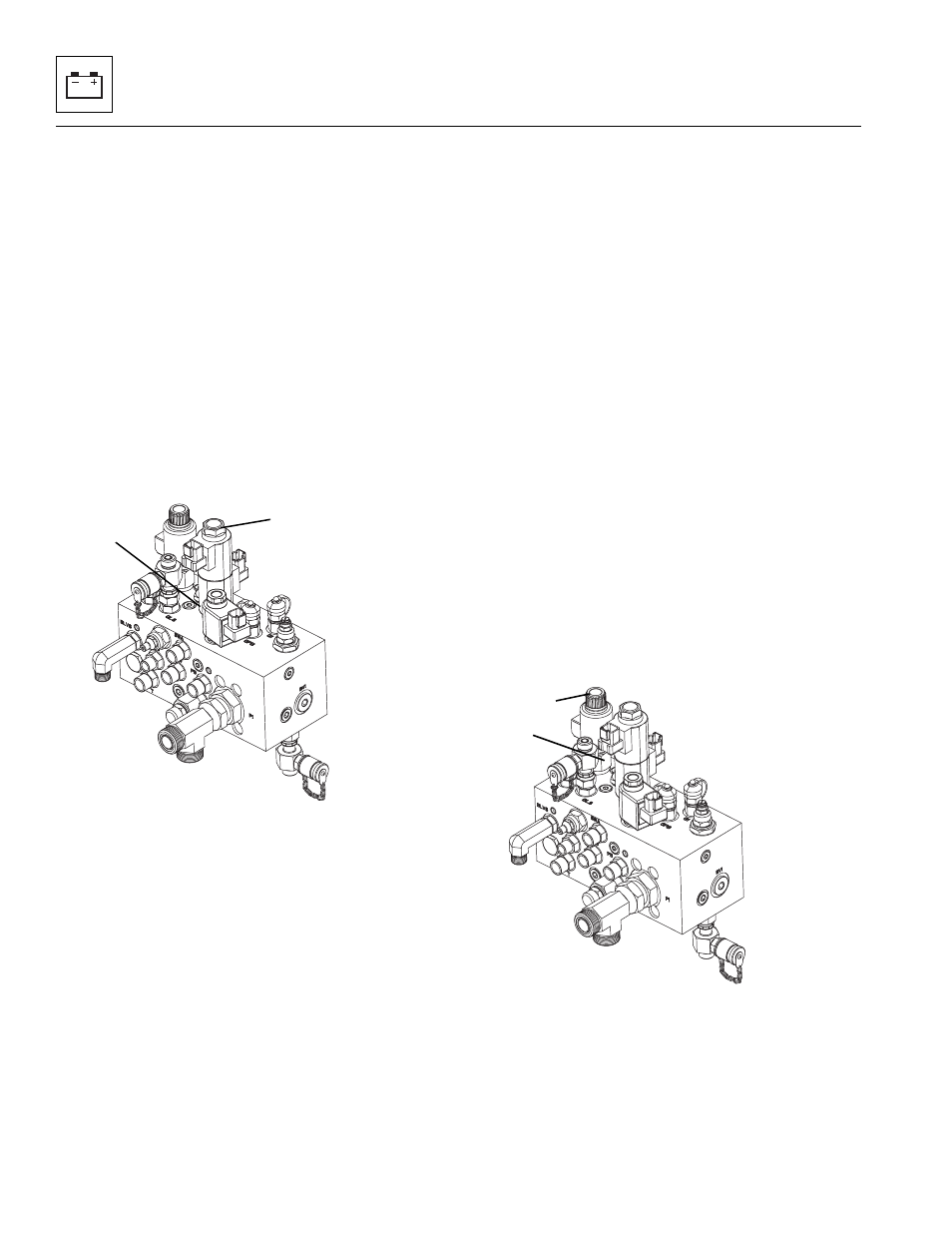

Pump Solenoid Valve

a. Pump Solenoid Valve Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the transmission control lever in

(N) NEUTRAL, engage the park brake and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Disconnect the battery negative (-) cable from the

battery negative (-) terminal.

5. Disconnect the wiring connector at the pump

solenoid lead.

6. Remove the nut on the end of the pump coil (5).

7. Remove the pump coil.

8. Remove the pump solenoid (6). (Remove only if the

electrical coil is found to not be faulty; cold

resistance approximately 3.7 ohm.)

b. Disassembly

DO NOT disassemble the solenoid. The solenoid is not

serviceable. Replace solenoid if found to be defective.

MAP04101

3

4

MAP04101

5

6