4 auxiliary valve, 5 telescope valve, Auxiliary valve – JLG G12-55A AccuPlace Service Manual User Manual

Page 107: Telescope valve

8.17

G10-55A & G12-55A AccuPlace

Hydraulic System

Note: This will ensure that there is approximately a 325

psi (22 bar) margin between the valve LS and pump

output.

8.8.4

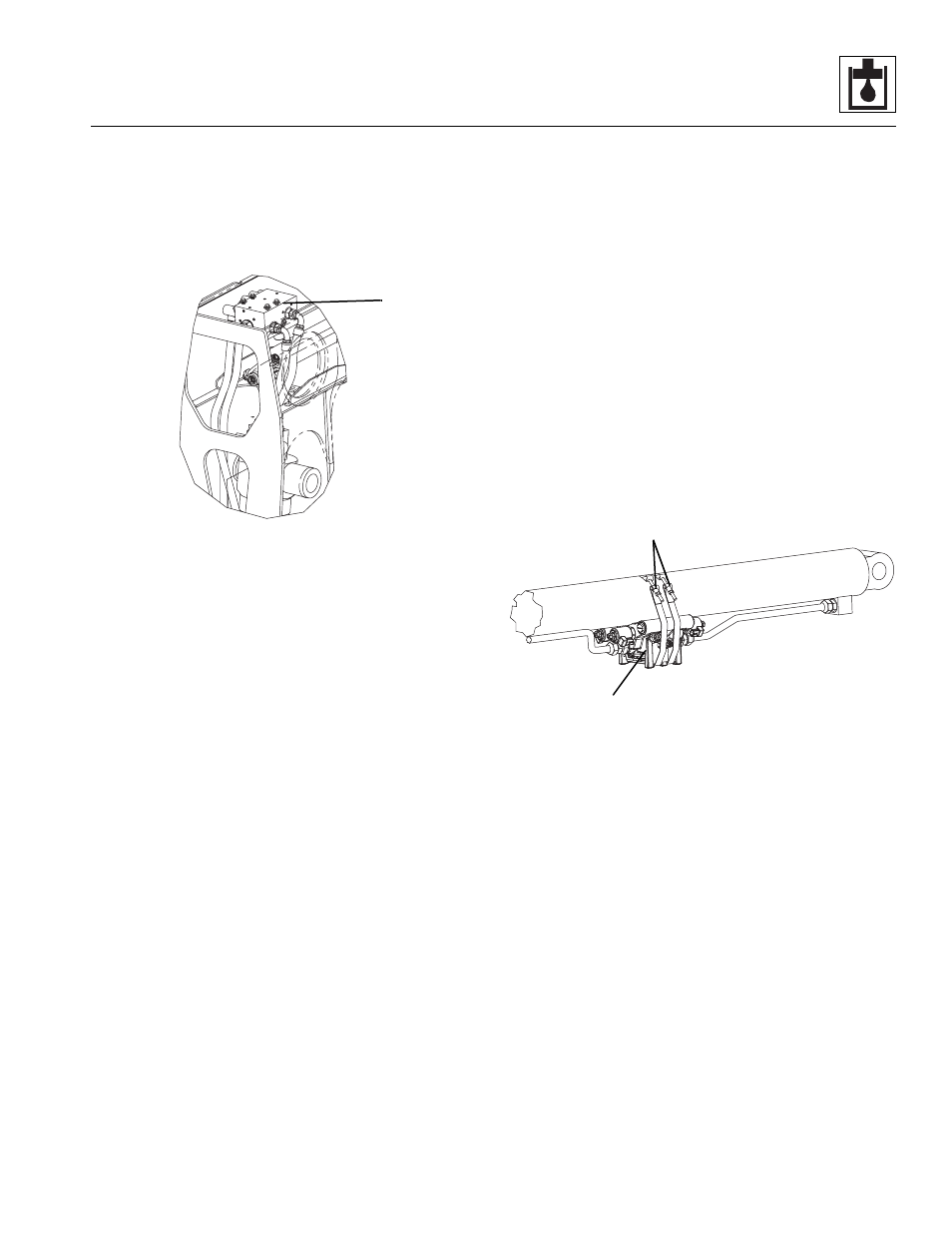

Auxiliary Valve

a. Auxiliary Valve Removal

1. Remove any attachment from the boom. Park the

machine on a firm, level surface, level the machine,

fully retract the boom, lower the boom, place the

transmission control lever in (N) NEUTRAL, engage

the park brake and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Disconnect the battery negative (-) cable from the

battery negative (-) terminal.

5. Remove the protective cover from the boomhead.

6. Thoroughly clean the valve and surrounding area,

including all hoses and fittings before proceeding.

7. Label, disconnect and cap the hydraulic hoses

attached to the auxiliary valve (8). Cap all fittings to

prevent dirt & debris from entering the hydraulic

system.

8. Label and disconnect the electrical connectors from

the auxiliary valve.

9. Remove the hardware securing the auxiliary valve to

the boomhead.

b. Auxiliary Valve Installation

1. Install the auxiliary valve to the boomhead with the

previously used hardware.

2. Connect the previously labeled electrical connectors

to the auxiliary valve.

3. Uncap and connect the previously labeled hydraulic

hoses to their appropriate locations.

4. Connect the battery negative (-) cable to the battery

negative (-) terminal.

5. Before starting the machine, check fluid level of the

hydraulic fluid reservoir and if necessary fill to full

mark with Mobilfluid 424

®

(ISO 46).

6. Start the machine and run at low idle for about one

minute. Test the functions of the auxiliary valve.

7. Inspect for leaks and check level of hydraulic fluid in

reservoir. Add hydraulic fluid if needed. Shut the

engine OFF.

8. Install the protective cover on the boomhead.

9. Close and secure the engine cover.

8.8.5

Telescope Valve

a. Telescope Valve Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the transmission control lever in (N) NEUTRAL,

engage the park brake and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Disconnect the battery negative (-) cable from the

battery negative (-) terminal.

5. Label, disconnect and cap the hydraulic hoses

attached to the telescope valve (9). Cap all fittings to

prevent dirt & debris from entering the hydraulic

system.

6. Label and disconnect the electrical connectors from

the telescope valve.

7. Support the telescope valve and remove the bolts on

the clamps (10) securing the telescope valve to the

extend cylinder.

MAP0250

8

MAP0710

10

9