AEM 30-71XX Infinity Stand-Alone Programmable Engine Mangement System Full Manual User Manual

Page 282

276

© 2014 AEM Performance Electronics

Infinity User Manual

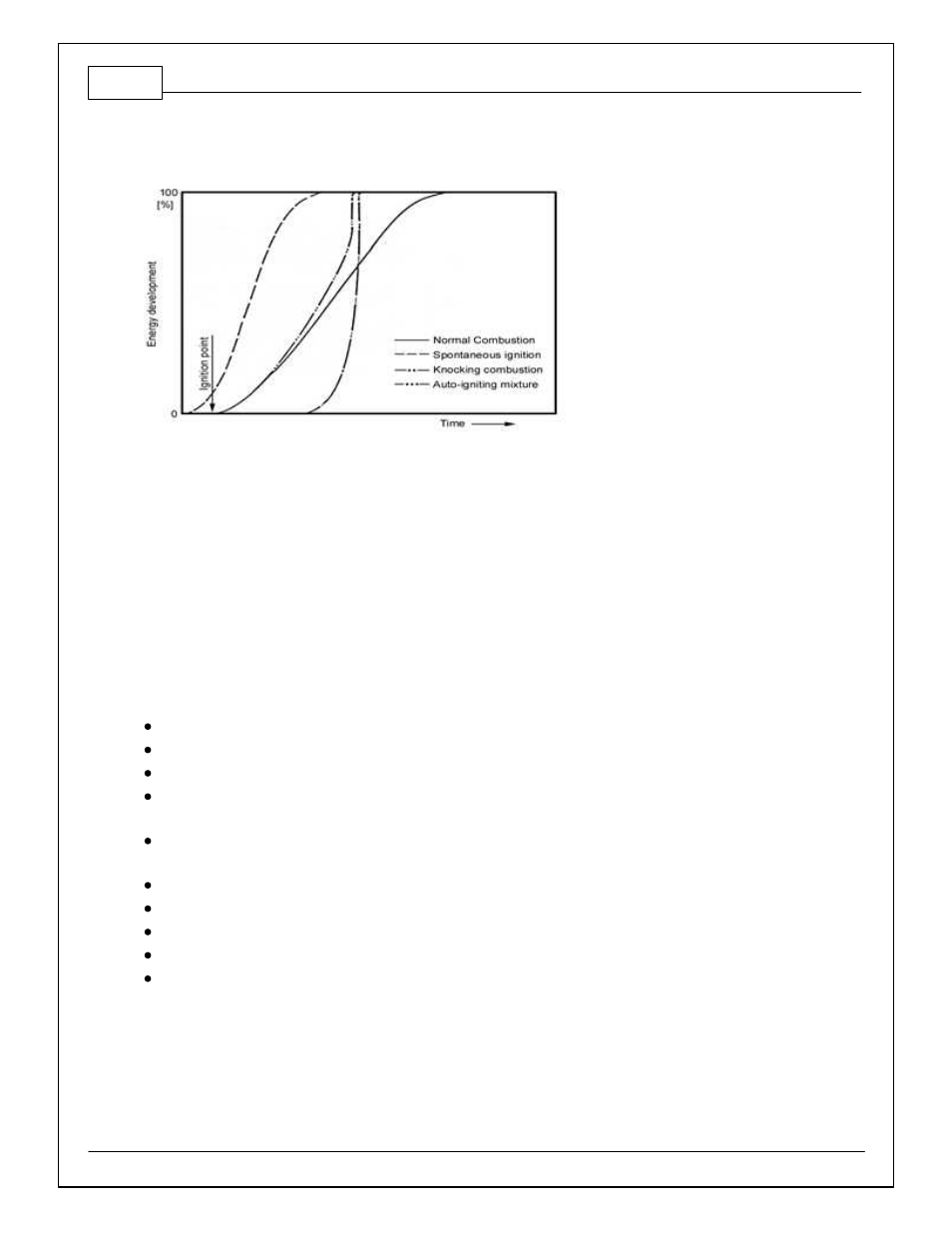

If the gasoline-air mixture auto-ignites somewhere in the cylinder (other than at the spark plug)

just after spark ignition, the auto-ignition combustion wave can collide with the spark-initiated

combustion wave, causing the vibration we hear as a knock or ping. Depending on its intensity,

knocking combustion may range from barely audible “pinging” to a rather violent thumping. The

point at which the knocking becomes damaging to the engine is dependent on the components

used in the engine. If sustained knocking occurs, then the pistons may be damaged. When

knocking reaches a violent thump, engine operation should be ceased or at minimum the load

and temperature reduced to prevent engine damage. Light knocking that happens during

acceleration is less harmful and may not damage the engine. Knocking tendency is increased by

the following design or operational characteristics:

High Engine loads encountered while towing a vehicle.

Using low octane gasoline in a high-compression engine.

Too much timing advance for the type of fuel being used.

Higher air density, (this can be caused by starting a calibration at high altitude and

then traveling to a lower one, or the addition of forced induction).

Increased temperatures and pressure in the combustion chamber due to inadequate

engine cooling.

Excessive inlet air temperature.

Spark plugs with an improperly high heat range.

A non-central spark plug location in the combustion chamber.

An elongated combustion chamber design.

Too lean of an air/fuel mixture.