AEM 30-71XX Infinity Stand-Alone Programmable Engine Mangement System Full Manual User Manual

Page 260

254

© 2014 AEM Performance Electronics

Infinity User Manual

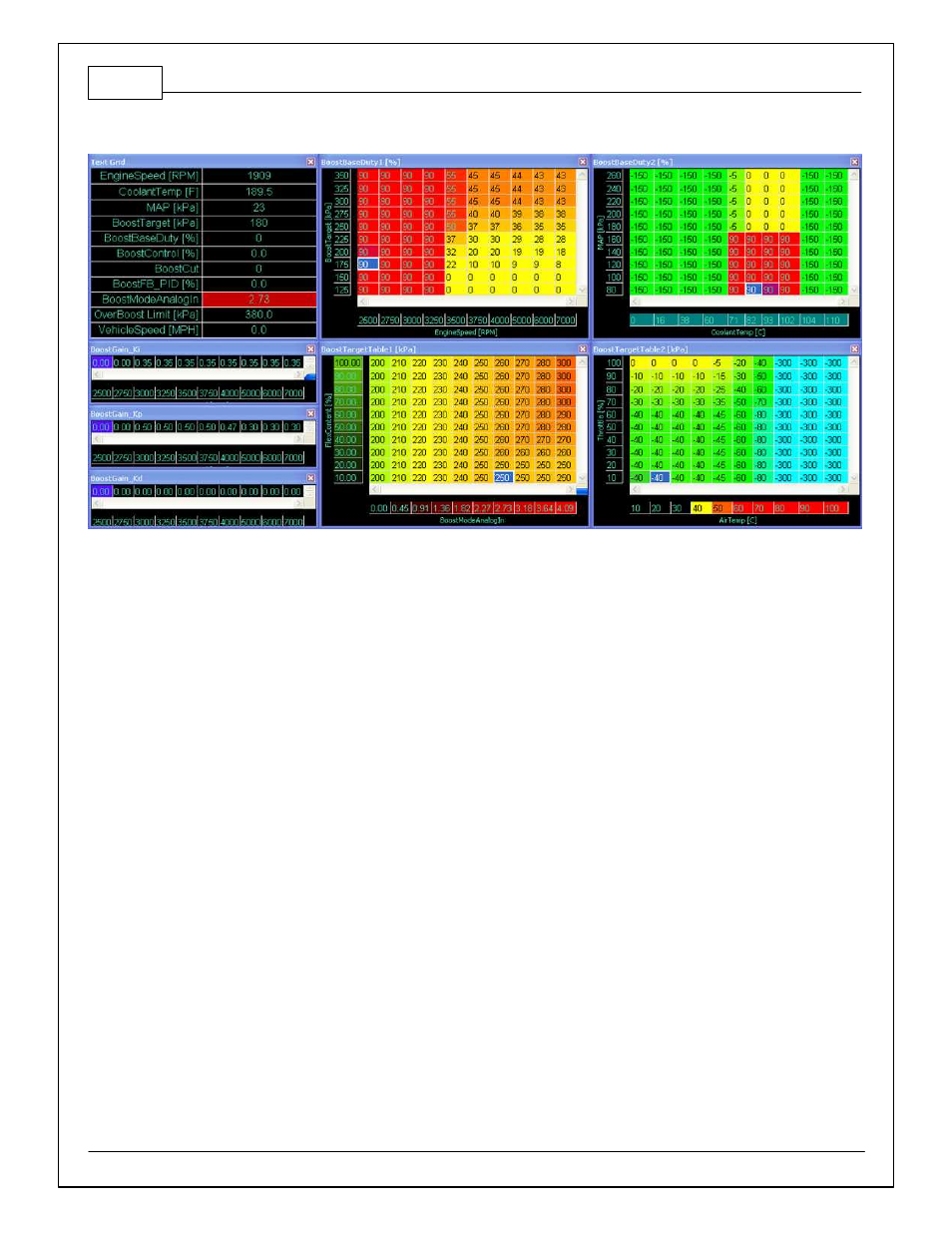

The example below is a boost strategy for a high horsepower, severely traction limited drag car

that runs on varying mixes of Ethanol. Boost compensated for changes in baro pressure

(weather, altitude, etc) and changes in exhaust backpressure. Typically, higher duty cycle is

needed to retain boost level as baro pressure is reduced and EBP is increased. However, due

to the Infinity's advanced PID system, you could theoretically get away without having these

sensors and still have consistent boost control by relying on boost feedback.

Failsafe strategies include injected pressure (this is the pressure delta between the fuel pressure

and manifold pressure). On a manifold-pressure-referenced fuel pressure regulator, injected

pressure should theoretically remain constant at all times, as the pressure regulator directly

combats changes to manifold pressure by changing fuel pressure in a 1:1 ratio. However, if there

is a pressure regulator failure, or a fuel flow issue (weak pump, restricted lines, etc) injected

pressure can drop. The boost control is set up to automatically reduce boost in this condition.

Side note: Due to the Infinity's model-based fuel calculations, any variation in injected pressure

will also be compensated for in fueling.

You'll notice that the boost target increases with each gear, as it should. Also, with higher Ethanol

contents, more boost can be run safely, but of course we only want this in the higher gears as

we're traction limited. However, it was found on this car that higher ethanol contents (at the same

boost level) caused an increase in torque due to the fuel/tuning, and this caused additional wheel

spin. Therefore, boost target is actually reduced slightly in lower gears and higher ethanol

contents to combat this tendency.