Installation – KROHNE ALTOSONIC V12 EN User Manual

Page 20

3

INSTALLATION

20

ALTOSONIC V12

www.krohne.com

04/2013 - 4002643502 - MA ALTOSONIC V12 R02 en

In order to install the gas flowmeter, the pipeline must have a slot of such length that the meter

including the gaskets fits nicely in the slot. It should not be necessary to use excessive force to

tighten the bolts in order to close the gaps on either side of the meter.

Nor should the slot be too small, implying the slot has to be widened by applying brute force to fit

the meter and gaskets in the slot.

For tightening the bolts of the flanges, apply a lubricant as required, in accordance with the

materials as used and applicable standards.

Tighten the bolts of the flanges with a torque according to the standards applicable to the

flanges and materials used.

3.5.2 Pipe diameters and lengths

Make sure that the inner diameter of upstream and downstream pipes matches the specified

connection diameter of the ultrasonic flowmeter within 1%. Contact KROHNE if the iner diameter

deviates more than 1%.

3.5.3 Flow conditioners

Although the flowmeter is a highly accurate device, an additional flow conditioner can be

installed upstream of the flowmeter in order to minimize measuring uncertainty, in particular

when a strongly distorted flow velocity profile has to be expected, or when the available space for

a metering run is critical. If a flow conditioner is used the total inlet length may be reduced to

only 5 DN: having 2 DN upstream of the flow conditioner and 3 DN in between the flow

conditioner and the flowmeter.

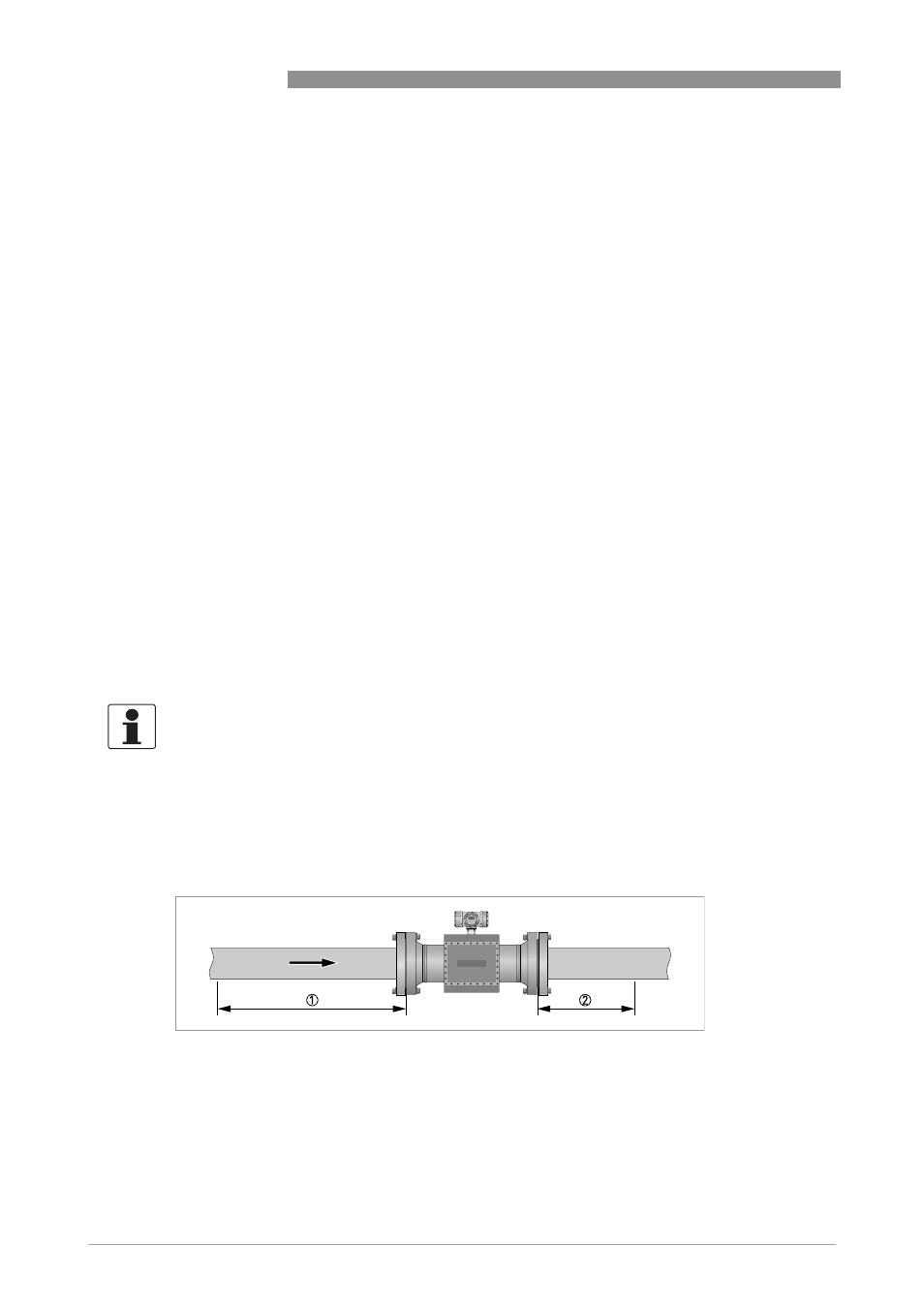

3.5.4 Inlet and outlet for uni-directional use

INFORMATION!

•

Preferred model is the

“

perforated plate

”

type. A

“

pipe bundle

”

type of flow conditioner is not

recommended.

•

When a flow conditioner is included in the metering run, it is strongly advised to use the same

flow conditioner and inlet pipe configuration during a flow (wet) calibration (see e.g. ISO17089

or AGA-9 for detailed requirements).

Without flow conditioner (OIML R137 class 0.5)

Figure 3-2: Reguired straight lengths for inlet and outlet

1 Inlet section: 10 DN

2 Outlet section: 3 DN