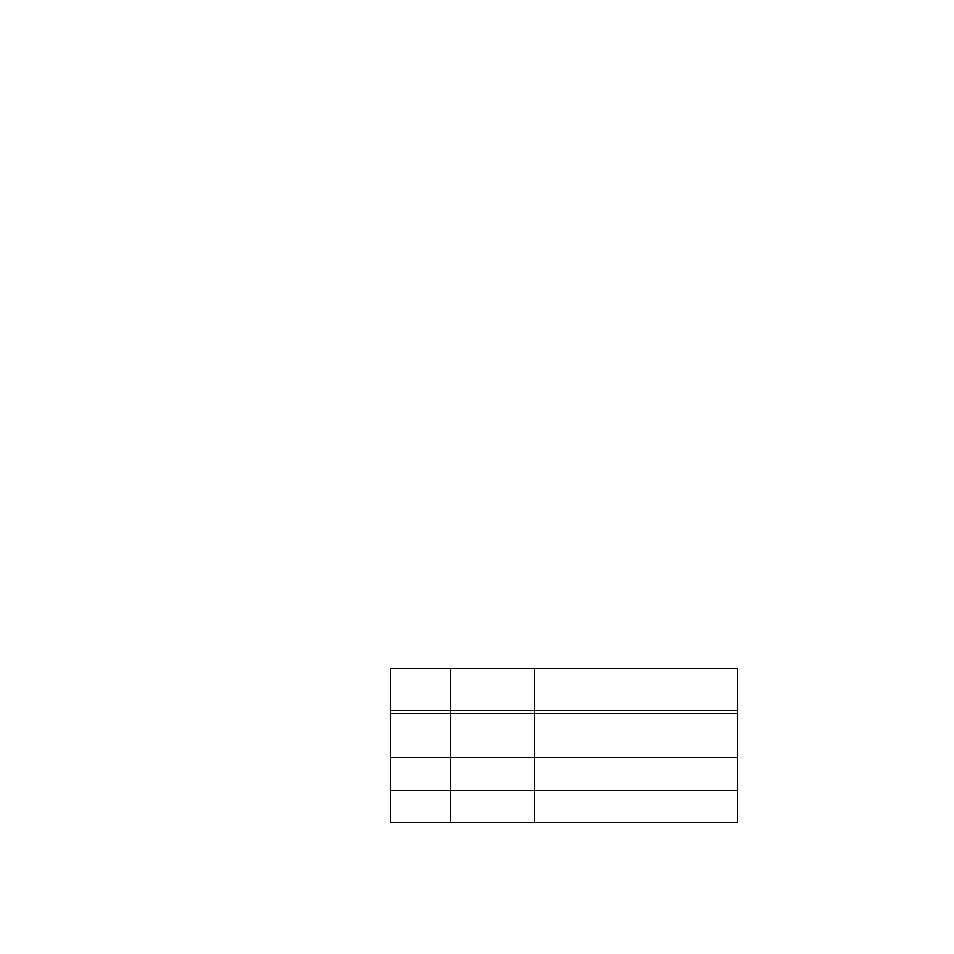

Table 5.21—heat/cool curve 184 – Watlow PPC-2000 User Manual

Page 210

Chapter 5: LogicPro and Modbus Reference

PPC-2000 User’s Guide

184

Watlow Anafaze

Doc.# 30002-00 Rev 2.3

Heat/Cool Cycle Time

Specify the time base in seconds for time proportional outputs.

The output percentage is proportioned over this time period.

For example, a 50% output with a 10-second cycle time is on for

5 seconds and off for 5 seconds. Output cycle time only affects

control when the corresponding output type is set to Digital Time

Proportioning (Time Prop).

Heat/Cool Scale Lo

A control output may be linearly scaled by setting this

parameter. Set the percent of the output range of the selected

Heat/Cool Output Type that should correspond to a calculated Heat/

Cool Output% of 0%.

This parameter is set in tenths of a percent. The valid range is

0 to 1000 and corresponds to 0.0% to 100.0%: for example, a

setting of 500 corresponds to 50.0%.

Heat/Cool Scale Hi

A control output may be linearly scaled by setting this

parameter. Set the percent of the output range of the selected

Heat/Cool Output Type that should correspond to a calculated Heat/

Cool Output% of 100%.

This parameter is set in tenths of a percent. The valid range is

0 to 1000 and corresponds to 0.0% to 100.0%: for example, a

setting of 500 corresponds to 50.0%.

Heat/Cool Curve

Use this register to choose which output scaling method is

used. Straight linear is used for most applications. Lag curves

are usually used in plastic extruder applications. Table 5.21 on

page 184 lists and describes the values to which this parameter

may be set. Figure 5.2 on page 185 illustrates the effects of the

options.

Table 5.21

Heat/Cool Curve

Value

AnaWin3

Name

Description

0

Straight lin-

ear

Output is unaffected and is set as

calculated by the closed-loop PID

calculation.

1

Lag curve A

Output is reduced somewhat from

calculated value.

2

Lag curve B

Output is further reduced from

calculated value.