Alarm delay, Alarm delay 96, Figure 3.2—process variable alarms 96 – Watlow PPC-2000 User Manual

Page 120

Chapter 3: Operating with AnaWin 3

PPC-2000 User’s Guide

96

Watlow Anafaze

Doc.# 30002-00 Rev 2.3

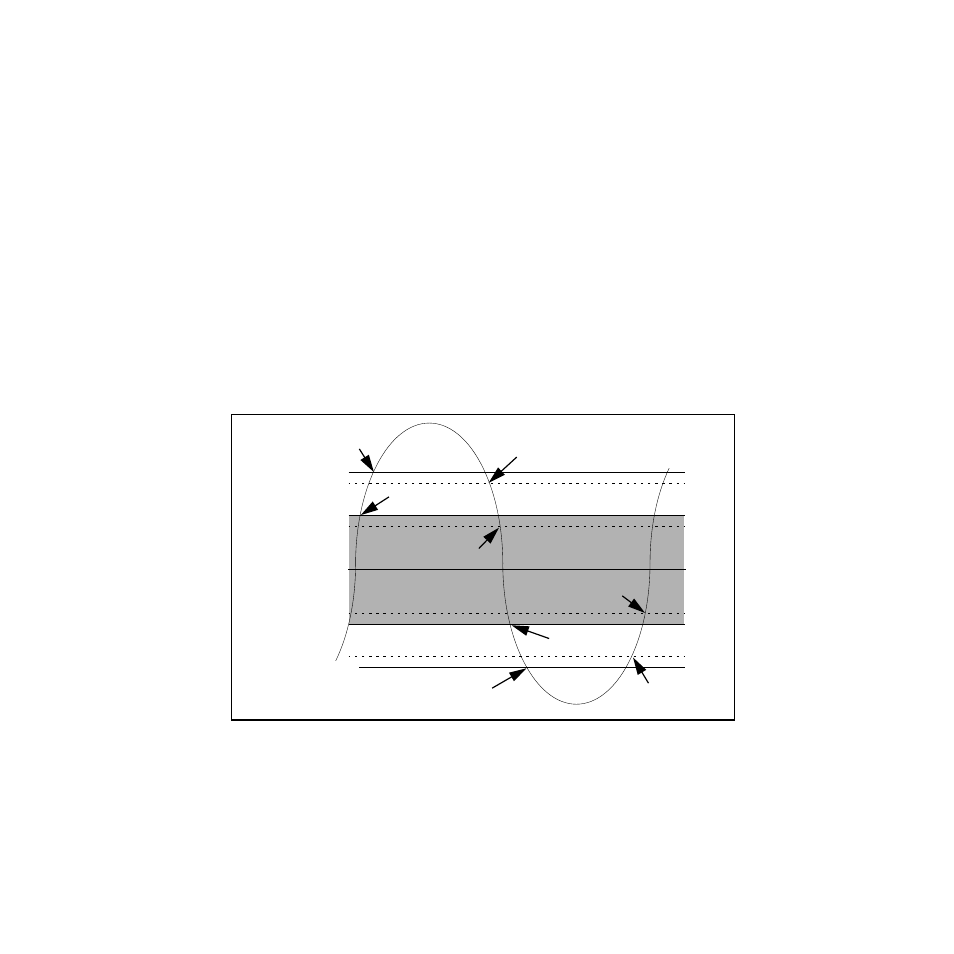

High and low process and deviation alarms activate when the

process variable goes outside the limits set by the user. The

alarm remains active until both the process variable comes

within the limit and the deadband, and the alarm is

acknowledged.

Any digital output not used as a control output can be assigned

to a process alarm. The output activates when the alarm is

active. Set the Logic of outputs used with alarms to determine

whether the alarm output turns on or off when an alarm occurs.

An alarm output remains active only as long as the process

variable remains outside the alarm limit and deadband. Once

the process variable is within the limit and deadband, the

output reverts to the inactive state. No alarm acknowledgment

is required.

When the controller powers up or the set point changes,

deviation alarms set to alarm type do not activate until the

process variable comes within the deviation alarm band,

preventing deviation alarms during a cold start. Deviation

alarms set to control type activate whenever the process

variable is outside the deviation band.

Figure 3.2

Process Variable Alarms

Alarm Delay

The controller may be configured to delay alarm reporting.

Alarm Delay delays failed sensor alarms and process alarms for

the channel. Only alarms that are continuously present for

longer than the alarm delay time are reported.

High Process alarm limit

SP + HD Offset

Set Point

SP - LD Offset

High Process alarm on

High Process alarm off

High Deviation

alarm on

High Deviation

alarm off

Low Deviation

alarm off

Low Deviation

alarm on

}

Deadband

}

Deadband

}

Deadband

}

Deadband

Low Process alarm on

Low Process alarm off

Low Process alarm limit