Table 3.9—primary channel parameter settings 107 – Watlow PPC-2000 User Manual

Page 131

PPC-2000 User’s Guide

Chapter 3: Operating with AnaWin 3

Doc.# 30002-00 Rev 2.3

Watlow Anafaze

107

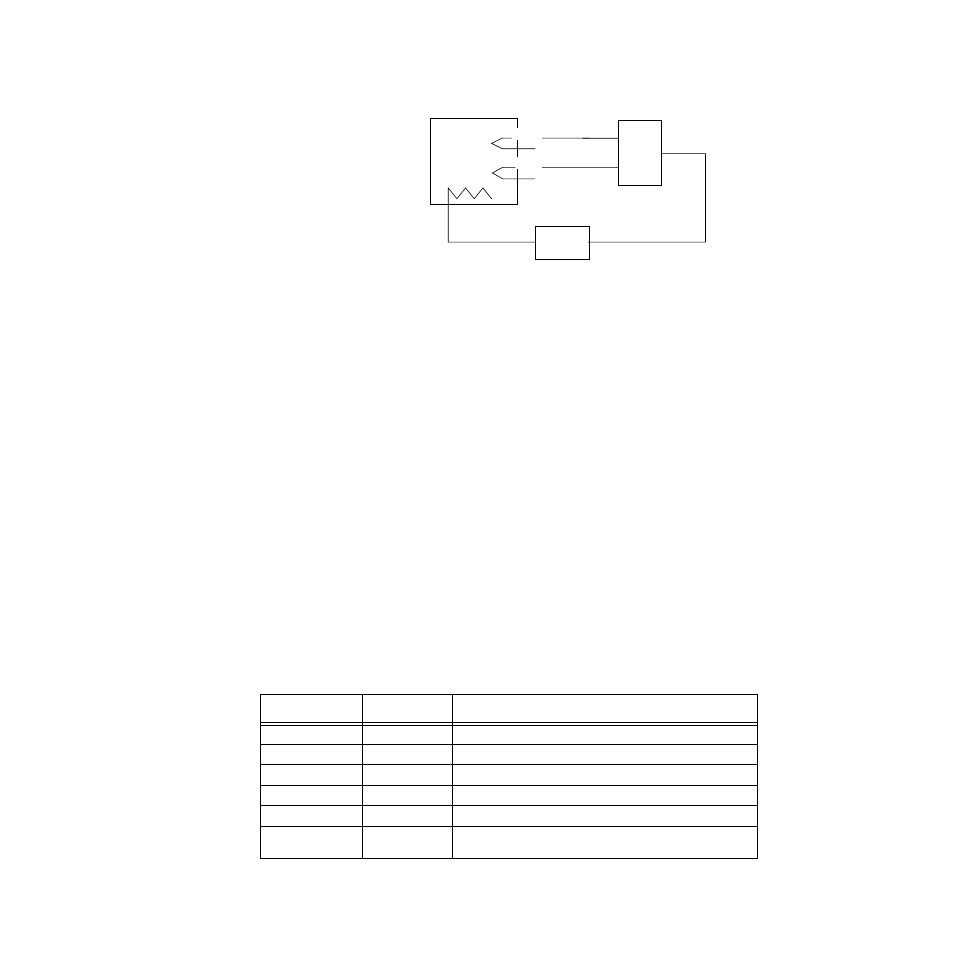

Figure 3.8

Sample Application Using

Cascade Control

For cascade control the inner TC is selected as the PV Source for

the primary channel, and the outer TC is selected as the PV

Source for the secondary channel. The secondary channel’s

output is used to control the heater.

An engineer familiar with the process has determined that as

the temperature of the inner (primary) TC drops from 150°F to

140°F, the set point of the secondary channel should rise from

150°F to 190°F. Table 3.9 and Table 3.10 on page 108 list the

parameter settings for the primary and secondary channels.

The PID parameters of the primary channel must be tuned to

produce the desired effect on the secondary channel’s set point.

The primary channel typically uses proportional only control.

Disabling the integral and derivative components of PID

makes the secondary set point a predictable function of the

primary channel’s process variable.

The proportional band is selected so the set point of the

secondary channel has the desired relationship to the process

variable of the primary channel. In this application, the

proportional band of the primary channel is set to 10°F.

Table 3.9

Primary Channel Parameter

Settings

Parameter

Setting

Description

PV Source

PPC1:AI 1.1

The inner TC is selected for the primary channel.

Set Point

150°F

The desired temperature at the inner TC.

Heat Prop Band

10

As the input drops 10°F, the output increases to 100%.

Heat Integral

0

Only proportional control is used.

Heat Derivative

0

Only proportional control is used.

Heat Output Dest

PPC1:Soft Bool

The primary output must be enabled, but is not used to drive

a load.

Power

Control

Tank

Heater

PPC

Channel 2 Heat Output

Inner TC Channel 1 Input

Outer TC Channel 2 Input

Outer

Inner

inner

outer

outer

outer