IAI America PCON-SE User Manual

Page 115

103

6. T

roubleshooting

(2)

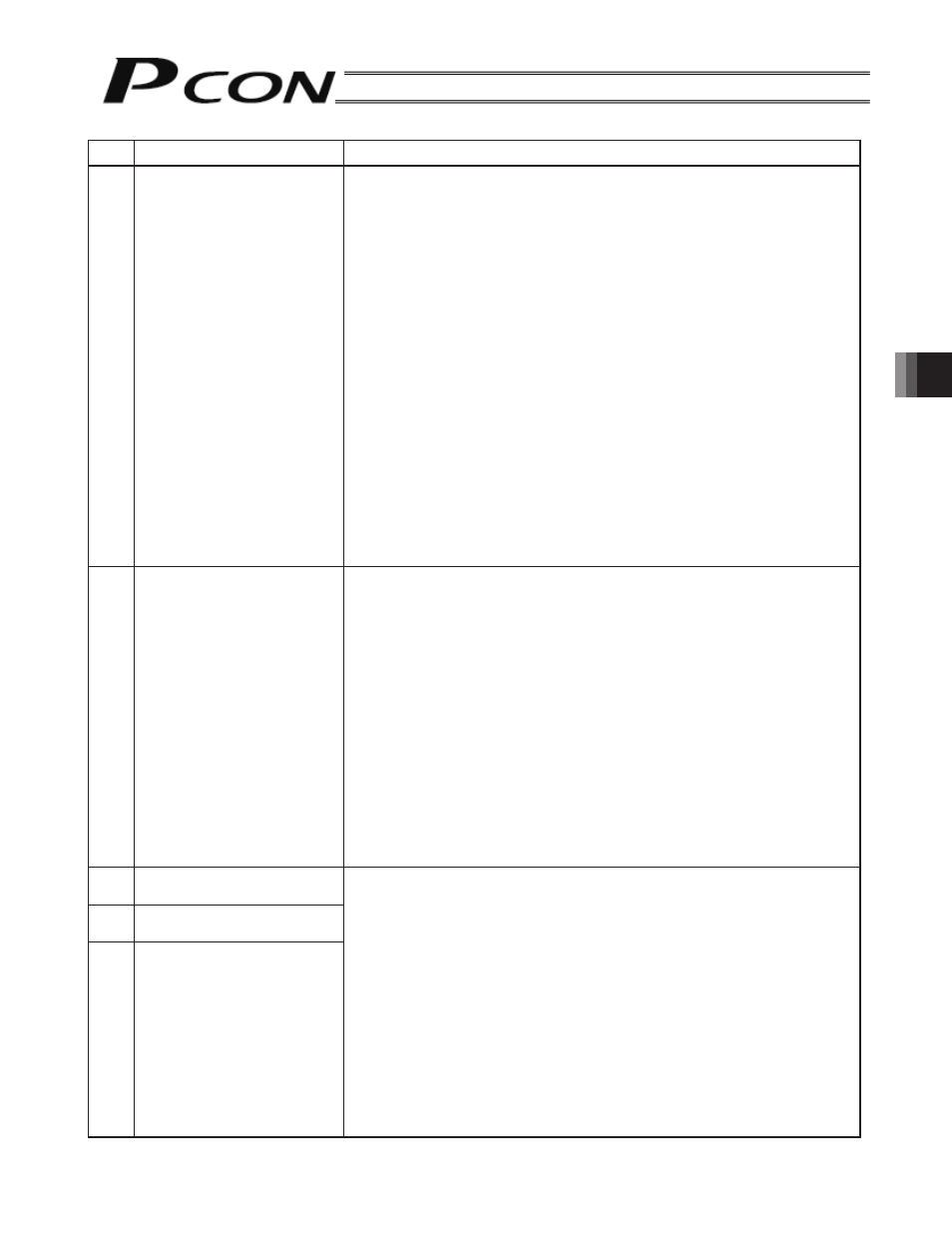

Cold-start level alarms

Code Error

name

Cause/Action

0B8

Excitation detection error

This control performs excited phase detection when the servo is turned

ON for the first time after the power has been input. When this error

generates, it means that the specified encoder signal level could not be

detected after 100 ms of excitation.

[1]

The connector of the motor relay cable is loose or its circuit is

open.

[2] If the actuator is equipped with a brake, the brake cannot be

released.

[3] Large motor load due to application of external force

[4] The power was input when the actuator was contacting the

mechanical end.

[5] Large slide resistance of the actuator itself

Action: [1] Check the wiring condition of the motor relay cable.

[2] Check the wiring condition of the brake cable, and also turn on/off

the brake release switch to see if the brake makes a “clicking”

sound.

[3] Check the assembly condition of mechanical parts for

abnormality.

[4] Move the actuator away from the mechanical end and then

reconnect the power.

[5] If the load weight is normal, cut off the power and move the

actuator by hand to check the slide resistance.

If the actuator is suspected to be the cause, please contact IAI.

0E5 Encoder receive error

Cause: [1] When the 24-V power supply is turned on, the controller power

turns on before the power to the simple absolute unit.

[2] When the

detailed code is H’0001:

The controller cannot communicate with the simple absolute unit

properly due to noise, etc.

[3] When the detailed code is H’0002:

The controller cannot

communicate with the simple absolute

unit properly due to a broken communication wire in the

encoder cable, etc.

Action: [1] Make sure the power to the simple absolute unit turns on

before (or at the same time as) the controller power.

[2]

Change the installation location of the controller. Install a FG,

noise filter, clamp filter or implement other noise elimination

measure.

[3] Check the connectors on the encoder relay cable between the

controller and simple

absolute unit for looseness. Or, replace

the cable.

0E8 Phase-A/B

disconnection

detection

0E9 Phase-A

disconnection

detection

0EA Phase-B

disconnection

detection

Encoder signals cannot be detected correctly.

Cause: [1] Loose or disconnected encoder-relay cable connector

[2] Loose or disconnected actuator-end connector of the supplied

cable

[3] When a high-thrust rod-type actuator or actuator is used in

combination with other types of actuators, the encoder relay

cables are combined wrongly.

Action: Check the connection condition of the encoder relay cable and

conduct a continuity check. If the results are normal, please

contact IAI.

If [3] is the case, check the model of each encoder relay cable and

connect the correct cable to each actuator without making wrong

combinations.

Cable model for high-thrust rod-type actuator: CB-RFA-PA***

Cable model for other types of actuators: CB-RCP2-PA***