IAI America PCON-SE User Manual

Page 114

102

6. T

roubleshooting

n

o

i

t

c

A

/

e

s

u

a

C

e

m

a

n

r

o

r

r

E

e

d

o

C

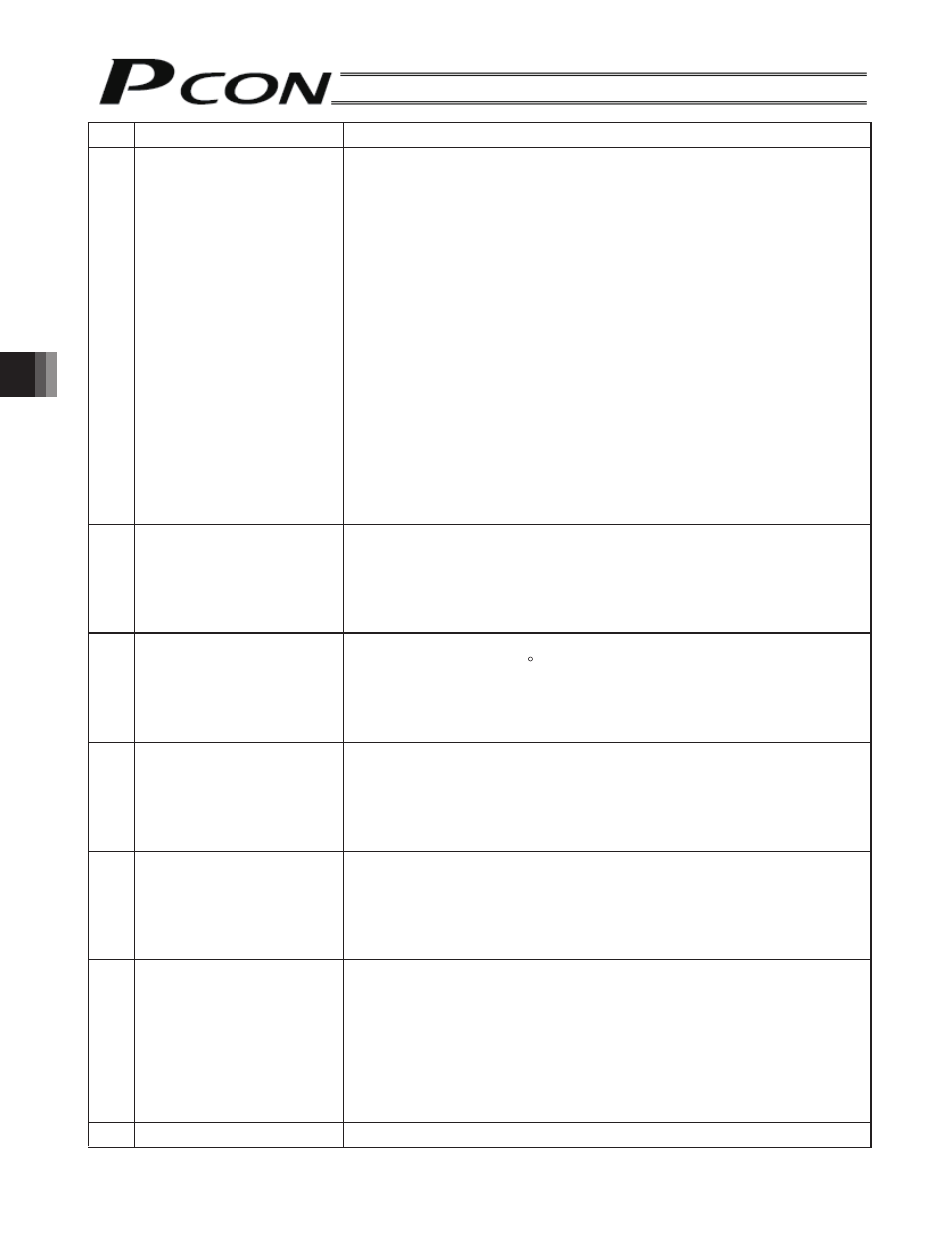

0C1 Servo error

When this error generates, it means that the motor could not operate for at

least 2 seconds after the move command was received and before the

target position was reached.

Cause: [1] The connector on the motor relay cable is loose or the cable is

broken.

[2] If the actuator has a brake, the brake cannot be released.

[3] The actuator is receiving a large load due to an external force.

[2] Check the wiring condition of the brake cable and turn on/off the

brake release switch repeatedly to see if the brake makes “click”

[3] Check the assembled conditions of mechanical parts for

abnormality.

[4] If the load weight is normal, turn off the power and try moving

0C9 Excessive motor supply

voltage

This alarm indicates that the motor supply voltage is excessive (24 V+20%,

28.8 V or more).

Cause: [1] High voltage of 24 V input power supply

[2] Faulty part inside the controller

Action: Check the voltage of the input power supply.

If the voltage is normal, please contact IAI.

0CA Overheating

This alarm indicates that the temperature around the power transistor in the

controller is excessive (95 C or more).

Cause: [1] High temperature around the controller

[2] Faulty internal controller part

Action: [1] Lower the surrounding air temperature of the controller.

If action [1] does not improves the situation, contact IAI.

0CC Abnormal control supply

voltage

This alarm indicates that the voltage of the 24 V input power supply is

excessive (24 V+20%: 28.8 V or more).

Cause: [1] High voltage of 24 V input power supply

[2] Faulty part inside the controller

Action: Check the voltage of the input power supply.

If the voltage is normal, please contact IAI.

0CE Drop in control supply

voltage

This alarm indicates that the voltage of the 24 V input power supply has

dropped (24 V-20%: 19.2V or less).

Cause: [1] Low voltage of the 24V input power supply

[2] Faulty part inside the controller

Action: Check the voltage of the input power supply.

If the voltage is normal, please contact IAI.

0D8 Deviation overflow

The position deviation counter has overflowed.

Cause: [1] The speed dropped during movement due to the effect of an

external force, etc.

[2] The acceleration setting is too high for the transferring mass.

Action: [1] Check the load conditions, such as whether the load is

contacting a surrounding object or the brake is released, and

then remove the cause.

[2] An overload condition is suspected, so review the load weight.

Reconnect the power and then perform home return.

0D9 Soft limit over error

This alarm indicates that a soft limit has been reached.

[4] The slide resistance of the actuator itself is high.

[5] The positioning band setting is smaller than the encoder resolution.

sounds.

Action [1] Check the wiring condition of the motor relay cable.

[5] Set the positioning band value greater than that of the encoder

resolution.

the actuator by hand to check the slide resistance.

If the actuator itself is suspected to be the cause, please

contact IAI.