Inertia compensation, Configuration – Rockwell Automation 20D PowerFlex 700S AC Drives with Phase II Control Reference Manual User Manual

Page 62

62

Rockwell Automation Publication PFLEX-RM003E-EN-E - January 2011

Chapter 1 Detailed Drive Operation

Configuration

See

Advanced Tuning for the Speed Regulator with

for details on using inertia adaption.

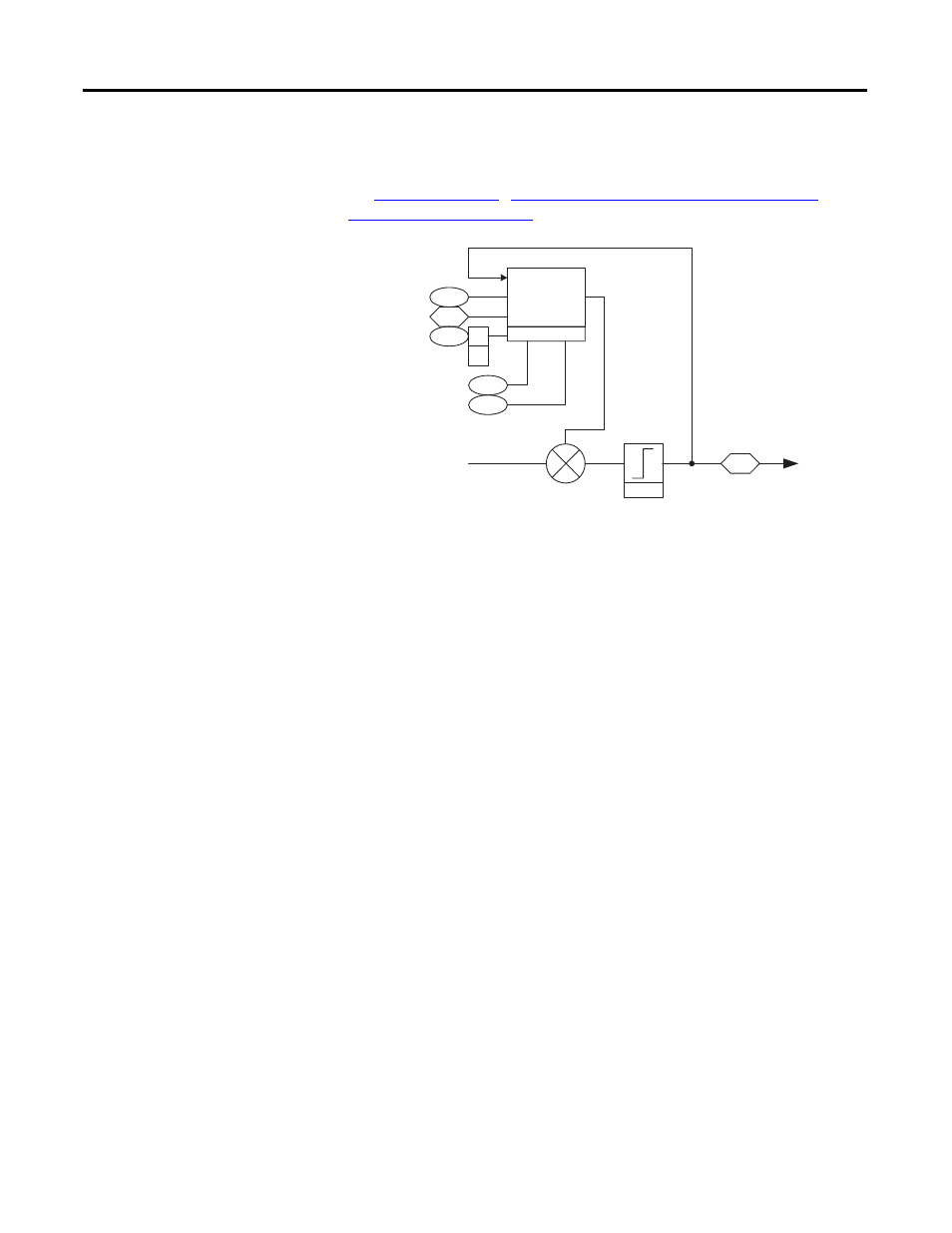

Inertia Compensation

During speed changes, a certain level of torque is required due to load inertia.

That level of torque is above the torque used to run at constant speed. Inertia

compensation calculates that torque based on the acceleration or deceleration

rate. Then that acceleration or deceleration torque can be fed forward into the

torque control, making for smoother accels and decels, especially with high

inertia loads.

Parameter 56 [Inertia SpeedRef ] is linked to parameter 43 [Ramped Spd Ref ].

This becomes the speed reference that the inertia compensation block uses to

calculate the acceleration or deceleration rate, also known as the derivative of

speed with respect to time.

Inertia compensation is enabled by turning on parameter 151 [Logic Command],

bit 10 “Inertia Comp”.

Parameter 9 [Total Inertia] is calculated during the autotune and is used along

with the calculated acceleration or deceleration rate to calculate the torque adder.

Parameter 57 [InertiaAccelGain] determines the gain for the inertia

compensation during acceleration. A gain of 1 results in 100% compensation.

Parameter 58 [InertiaDecelGain] determines the gain for the inertia

compensation during deceleration.

Parameter 60 [DeltaSpeedScale] is a multiplier for the torque output of the

inertia compensation block. It is used in center wind and center unwind

applications to compensate for diameter build-up.

Limit

303

Motor Torque Ref

Inertia

Adaptation

9

300

Total Inertia

Motor Spd Fdbk

132

00

01

Inert Adapt Sel

(Inrtia Adapt )

(Load Est )

133

134

Inert Adapt BW

Inert Adapt Gain

-

+

From Spd /Torque

Mode Selection

To Current

Control

Torque Limits