Friction compensation virtual encoder, Friction compensation, Virtual encoder – Rockwell Automation 20D PowerFlex 700S AC Drives with Phase II Control Reference Manual User Manual

Page 150

150

Rockwell Automation Publication PFLEX-RM003E-EN-E - January 2011

Chapter 1 Detailed Drive Operation

Friction Compensation

The friction compensation block is used to calculate breakaway torque and the

torque required to keep the motor running at a constant speed due to friction.

For more information on friction compensation, see

.

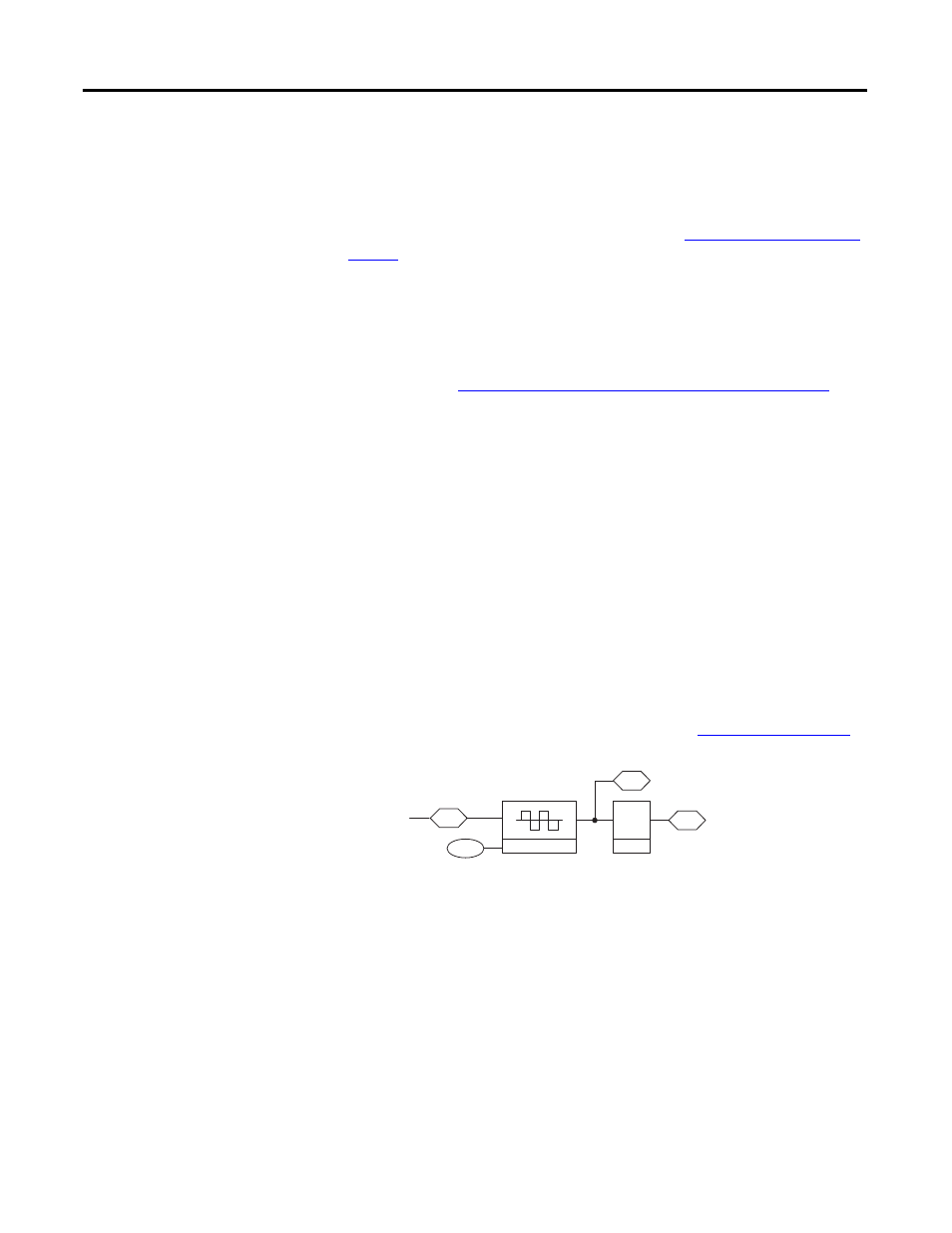

Virtual Encoder

The virtual encoder can be used as a position master for position follower

applications (see

Position Loop - Follower (Electronic Gearing) on page 90

for

details on position control). The advantage of following a virtual encoder instead

of actual encoder feedback is that the virtual encoder reference is much smoother

and is not subject to noise.

The virtual encoder block generates a position counter based on the speed

reference in parameter 43 [Ramped Spd Ref ]. Parameter 61 [Virt Encoder EPR]

is used to specify the desired edges per revolution for the virtual encoder. For

example if parameter 61 is 4096 EPR, this would be equivalent to a 1024 PPR

quadrature encoder.

Parameter 62 [Virt Encdr Posit] is a 32-bit integer that contains the pulse count

output of the virtual encoder block.

Parameter 63 [Virt Encdr Dlyed] is a 32-bit integer that contains the pulse count

output of the virtual encoder block delayed by one scan of the speed reference

loop. This parameter can be used to send a virtual position reference over

SynchLink for position follower applications. Refer to

for more details.

61

62

63

Virtual Encoder

Virt Encoder EPR

Delay

One

Scan

43

Ramped Spd Ref

from Ramp

Virt Encdr Posit

Virt Encdr Dlyed