Analog outputs, Analog output specifications, Analog output configuration – Rockwell Automation 20D PowerFlex 700S AC Drives with Phase II Control Reference Manual User Manual

Page 17

Rockwell Automation Publication PFLEX-RM003E-EN-E - January 2011

17

Detailed Drive Operation Chapter 1

Analog Outputs

Analog Output Specifications

There are two analog outputs, differential, configurable for +/-10V or 0…20 mA.

The D/A (digital to analog) converter is 11 bits plus the sign bit.

Analog Output Configuration

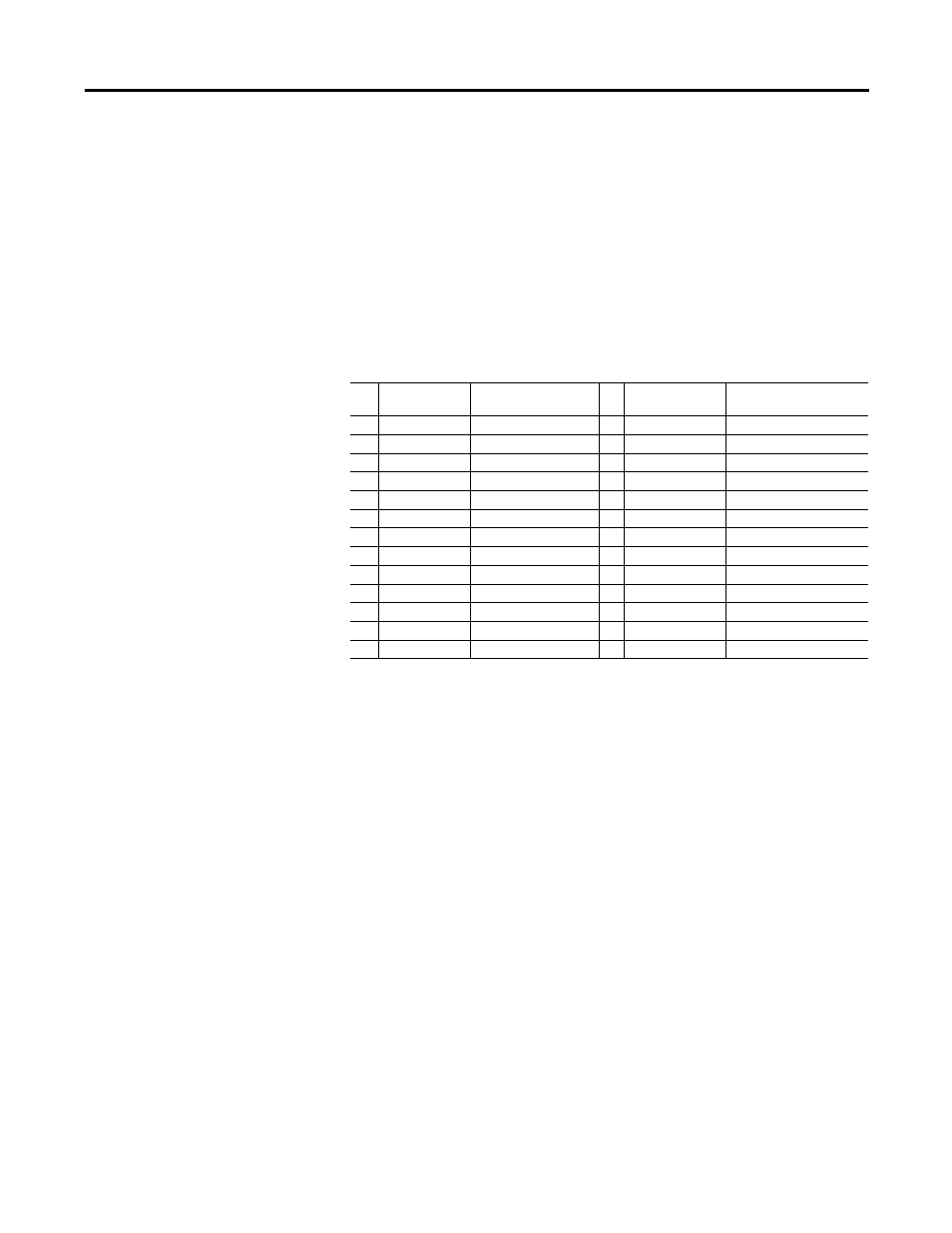

Parameters 831 and 838 [Anlg Out

x Sel] are use to specify the signal used on

Analog Outputs 1 and 2, respectively. These parameters can be programmed to

the following selections:

*Additionally, the analog output can be user configured for some other value by

setting [Anlg Out

x Sel] to 0 “User Select” and linking either parameter 832 or

839 [Anlg Out

x DInt] to a DInt (double integer) parameter or linking parameter

833 or 840 [Anlg Out

x Real] to a floating point (real) parameter.

Parameter 834 or 841 [Anlg Out

x Offset] is added to [Anlg Outx Real] or [Anlg

Out

x DInt] before the scaling and limiting blocks.

The result of [Anlg Out

x Offset] plus [Anlg Outx Real] or [Anlg Outx DInt] is

limited by 10 times the value of parameter 835 or 842 [Anlg Out

x Scale]. Then

that limited value is divided by the value of [Anlg Out

x Scale].

Parameter 836 or 843 [Anlg Out

x Zero] is added after the scaling and limiting of

the analog output value. [Anlg Out

x Zero] can be used to null out any offset from

the D/A converter.

Parameter 837 or 844 [Anlg Out

x Value] displays the voltage or current value for

the analog output.

Bit Selection

Corresponding

Parameter

Bit Selection

Corresponding

Parameter

0

“User Select”

(*see below)

15 “Motor TrqRef”

303 [Motor Torque Ref]

1

“Output Freq”

310 [Output Freq]

16 “MtrTrqCurRef”

305 [Mtr Trq Curr Ref]

2

“Sel Spd Ref”

40 [Selected Spd Ref]

17 “Speed Ref”

301 [Motor Speed Ref]

3

“Output Curr”

308 [Output Current]

18 “Speed Fdbk”

71 [Filtered SpdFdbk]

4

“Trq Cur (Iq)”

499 [Trq Cur Fdbk (Iq)]

19 “Torque Est”

471 [Estimated Torque]

5

“% Motor Flux” 309 [% Motor Flux]

20 “Scl Spd Fdbk”

72 [Scaled Spd Fdbk]

6

“Output Power” 311 [Output Power]

21 “RampedSpdRef” 43 [Ramped Spd Ref]

7

“Output Volts”

307 [Output Voltage]

22 “Spd Reg Out”

101 [SpdReg Integ Out]

8

“DC Bus Volts”

306 [DC Bus Voltage]

23 “MOP Level”

1090 [MOP Level Real]

9

“PI Reference”

181 [PI Reference]

24 “Trend 1 DInt”

572 [Trend Out1 DInt]

10

“PI Feedback”

182 [PI Feedback]

25 “Trend 1 Real”

573 [Trend Out1 Real]

11

“PI Error”

183 [PI Error]

26 “Trend 2 DInt”

576 [Trend Out2 DInt]

12

“PI Output”

180 [PI Output]

27 “Trend 2 Real”

577 [Trend Out2 Real]