3ć28, 6 i/o assignments – Rockwell Automation 1772-LP3 PLC - 2/30 Programmable Controller Programming and Operations Manual User Manual

Page 55

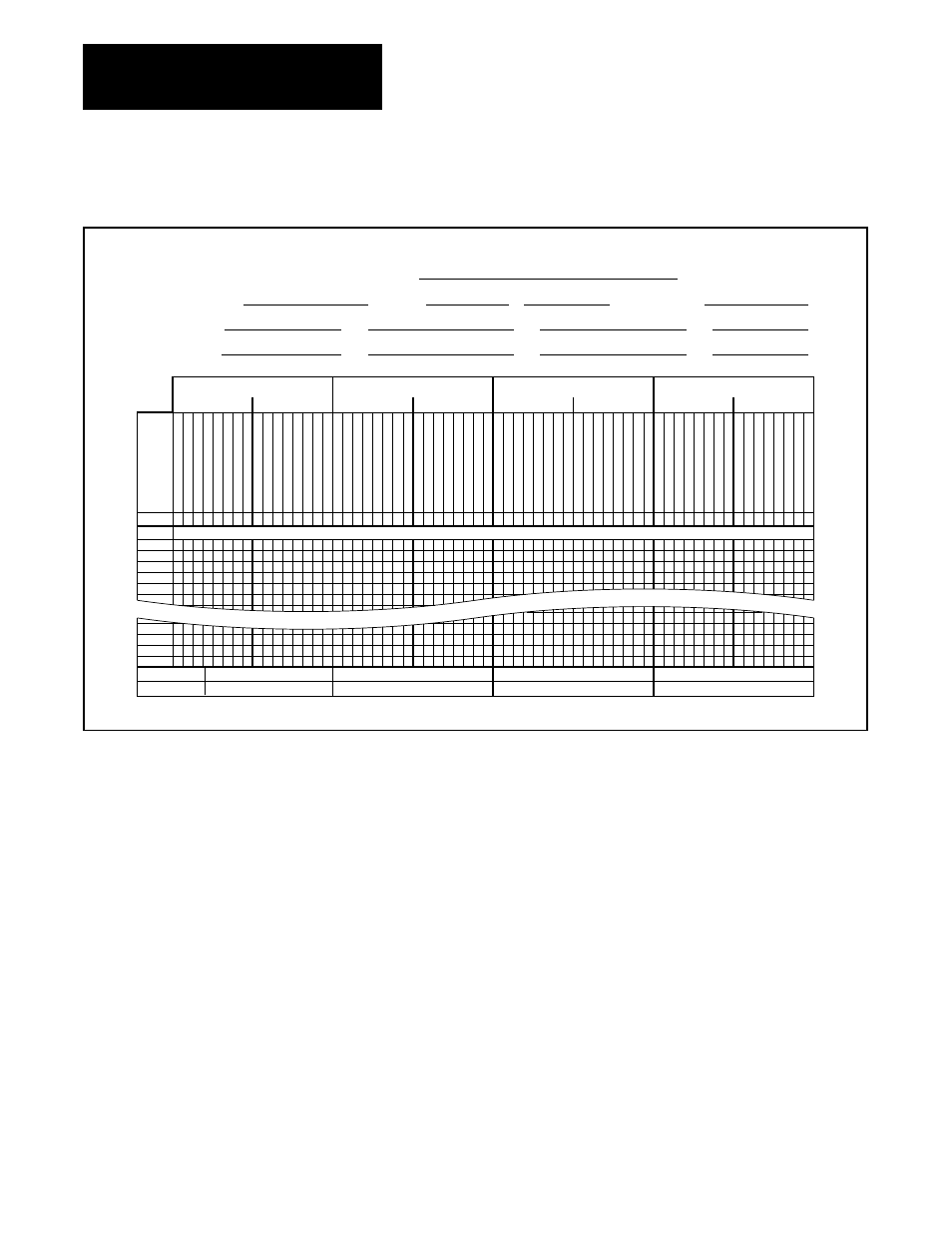

Data Table

Chapter 3

3Ć28

Figure 3.12

Example of Sequencer Table Bit Assignments

SEQUENCERą

COUNTER ADDR:ą FILE to

SEQ LENGTH

WORD ADDR:ą

MASK ADDR:ą

MASK

STEP

17 10 07 00

FROM ADDR

TO ADDR

17 10 07 00 17 10 07 00 17 10 07 00

WORD #1 WORD #2 WORD #3 WORD #4

D

E

V

I

C

E

N

A

M

E

1 0 1 0 0 1

1 0 1 0 1 0 1 0 1 0 1 0 1 0 0 1

1 0 1 0 1 0 1 0 1 0 1 0 1 0 0 1

1 0 1 0 1 0 1 0 1 0

0 0 1 0 1 0

0 0 1 0 0 1 0 0 1 0 1 0 1 0 0 1

1 0 1 0 1 0 1 0 1 0 1 0 1 0 0 1

1 0 1 0 1 0 1 0 1 0

A

B

F

8

E

A

4

C

A

3

D

9

3

C

4

D

2

8

1

2

B

5

F

4

1

D

C

1

3

4

D

2

C

FF

2

6

5

E

C

H

1

2

7

F

C

D

4

6

1

4

7

D

2

3

9

B

1

A

B

C

6

B

3

F

8

2

3

F

E

1

C

2

A

400 410 420

407 417 427

1

2

3

4

6

7

A

/ / / / / /

/ / / / / / / / / / / / / / / /

/ / / / / / / / / / / / / / / /

/ / / / / / 0 0 0 0

Input

204 400 427

112 113 114

403 431 432

1

Once the rough sketch of the application is complete, the programmer can

assign data table bit addresses to the input and output devices wired to the

controller. The 5-digit bit address directly corresponds to the location of

each I/O device with respect to the rack number, I/O group and terminal

number. Because the bit address is hardware-related, the programmer

cannot arbitrarily assign bit addresses to I/O devices. Refer to Section

3.2 on memory organization. Analog modules and other intelligent I/O

modules use word addresses rather than 5-digit bit addresses. Refer to the

user’s manual for each module for more information on addressing and

wiring.

The installer and programmer of the PLC-2/30 Programmable Controller

should work together to determine the best placement of the I/O modules

within the I/O chassis. To simplify installation and troubleshooting

procedures, it may be desirable to group like modules together. It is also

helpful to document I/O assignments on a form such as the form presented

at the end of this section. Recommendations for I/O wiring and module

3.4.6

I/O Assignments