10 troubleshooting – Festo DGC-HD User Manual

Page 28

DGC-HD

28

Festo – DGC-HD – 1304NH English

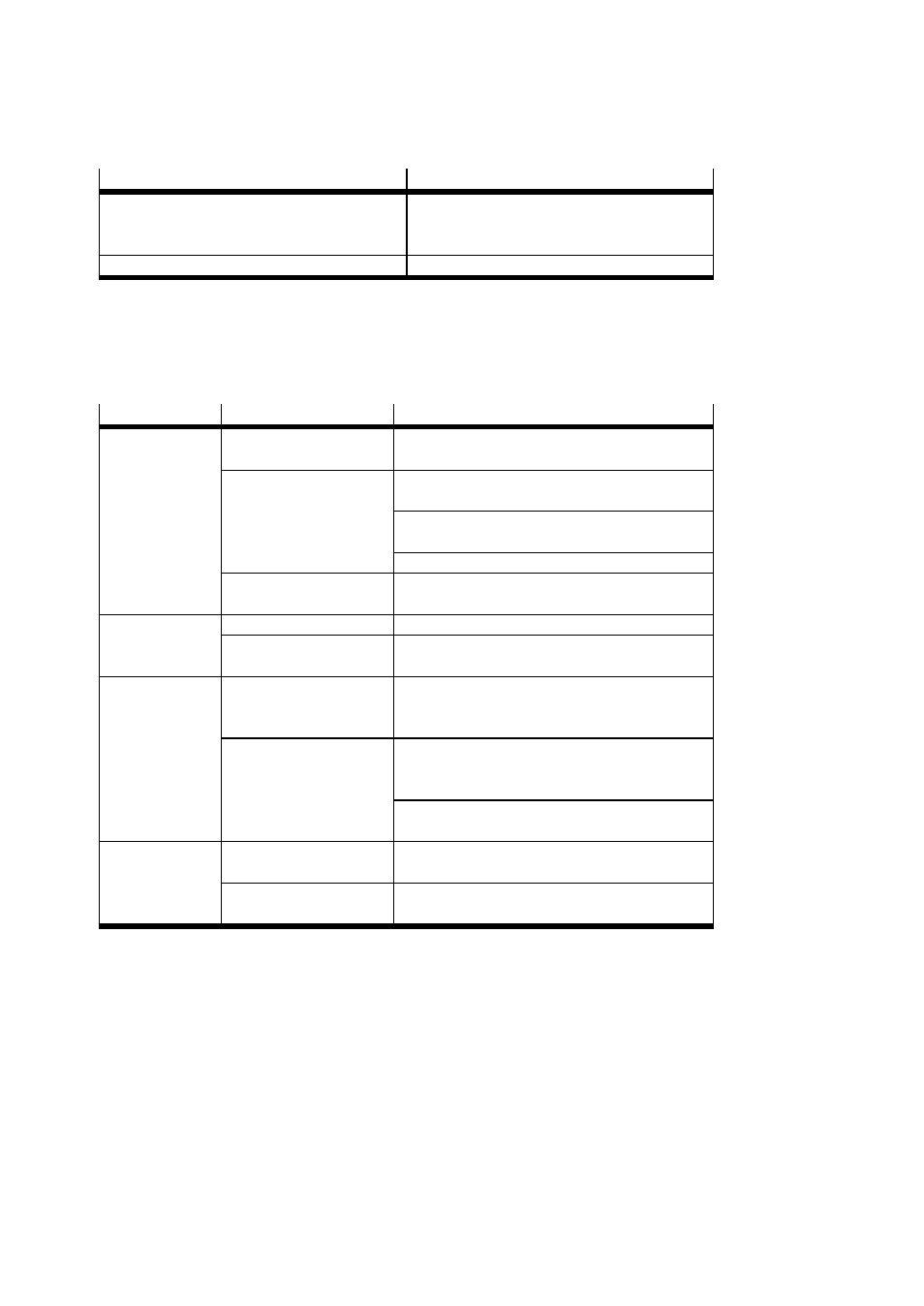

Designation

Part number/type

Grease gun with needle-pointed nozzle

Nozzle pipe, axial outlet port

Nozzle pipe, radial outlet port

647958/LUB-1

1)

647959/LUB-1-TR-I

1)

647960/LUB-1-TR-L

1)

Roller bearing grease

LUB-KC1 from Festo

1)

1)

(

Spare parts catalogue at www.festo.com/spareparts)

Tab. 7

10

Troubleshooting

Malfunction

Possible cause

Remedy

Uneven movement

of the slide

One-way flow control valve

not installed correctly

If possible reduce the exhaust (not the supply air)

Tension

Install the DGC-HD free of tension (evenness of the

bearing surface:

5.1 Mechanical installation)

Align the DGC-HD so that it is exactly parallel to the

second axis

Grease the DGC-HD (

8 Service and maintenance)

Roller bearing/bearing

guide defective

Return DGC-HD to Festo for repairs

Slide does not

move

Loads too high

Reduce mass of the effective load/travel speed

Mounting screws for

effective load too long

Observe max. screw-in depth

(

5.1.2 Installation of the effective load)

Heavy leakage

Seal worn

Replace worn parts:

–

yourself with set of wearing parts

–

send product to Festo for repairs

Sealing band pressed/

sucked in

When the linear drive is unpressurized, move the

slide twice manually through the entire stroke

(if necessary, move fixed stops into the end position)

Avoid low pressure in the piston chamber

(e.g. only move the unpressurized slide slowly)

Cylinder does not

reach the desired

speed

Air volume lacking

–

Increase connection cross-sections

–

Connect volumes in series

High friction or

counteracting force

Observe limits

Tab. 8