Festo DRRD-...-PS1 User Manual

Drrd-...-ps1

DRRD-...-PS1

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

Enclosure for operating instructions

8003697

1308NH

[8028343]

Original: de

Intermediate-position module DRRD-...-PS1

English

. . . . . . . . . . . . . . . . . . . . . . . .

Note

• Observe the warnings and notes in the operating instructions for the DRRD

semi-rotary drive.

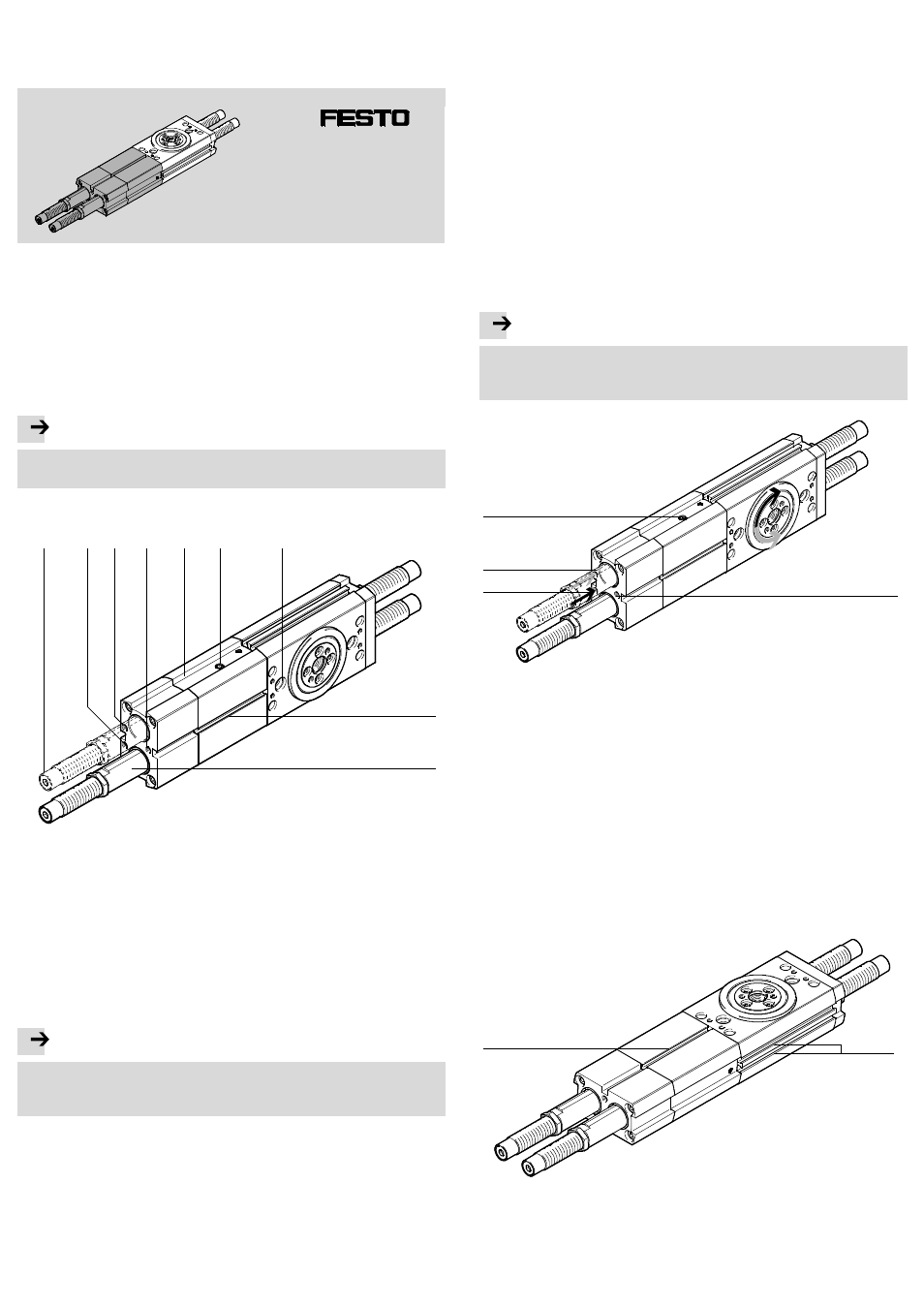

1

Control sections and connections

1

2

4

5

3

6

7

8

9

1 Shock absorbers or P-absorbers

secured with lock nut (2x)

2 Supply port for semi-rotary drive

(swivel clockwise)

3 Supply port for semi-rotary drive

(swivel anti-clockwise)

4 Compressed air supply port for

intermediate-position module

5 Intermediate-position module

DRRD-...-PS1

6 Venting hole with filter

7 Fastening interface at semi-rotary

drive DRRD (2x)

8 Slot for cylinder switch (2x)

9 Sleeve for reception of the shock

absorber (2x)

Fig. 1

2

Function and application

Note

The semi-rotary drive with intermediate-position module DRRD-...-PS1 can be

destroyed through incorrect use.

• Make sure that the intermediate-position module is throttled.

The intermediate-position module DRRD-...-PS1 is intended to permit positioning

of the flanged shaft in half of the nominal rotation angle of the semi-rotary drive

DRRD. This intermediate position can be travelled through.

3

Transport and storage

• Take into account the weight of the semi-rotary drive with intermediate-position

module.

Depending on the design, the DRRD-...-PS1 weights up to 20 kg.

• Transport the DRRD-...-PS1 by grasping the housing. Transporting it by grabbing

the dampeners

1 is not recommended, since the dampeners of the intermedi-

ate position can move axially (no safe stop).

4

Installation

4.1 Installation, mechanical

• Secure the semi-rotary drive at the intended position and the effective load to

the drive flange (

Operating instructions DRRD).

4.2 Installation, pneumatic

• Connect tubes to the supply ports (

Fig. 2):

– intermediate position

4

– semi-rotary drive

2 (swivel clockwise)

– semi-rotary drive

3 (swivel anti-clockwise).

Note

Sucked-in contamination and fluids disturb the function.

– Keep venting hole

6 clean and dry.

– Do not cover venting hole

6.

2

3

4

6

Fig. 2

To set the swivel speed at the semi-rotary drive:

• Use one-way flow control valves in all supply ports:

– for DRRD-16/20 as close as possible to the supply ports

– for DRRD-25 … 50 screwed directly into the supply ports.

For vertical installation and eccentric loads:

• Use the controlled throttle check valves HGL or an air reservoir VZS.

In this way you can prevent the effective load from sliding down suddenly if

there is a sudden pressure drop.

4.3 Installation, electric

• Place the cylinder switches in the slots

aJ to interrogate the intermediate posi-

tion directly at the semi-rotary drive. Slot

8 can be used to interrogate the

intermediate position piston.

aJ

8

Fig. 3