6 commissioning, 6commissioning – Festo DGC-HD User Manual

Page 25

DGC-HD

Festo – DGC-HD – 1304NH English

25

6

Commissioning

Before each commissioning and in operation:

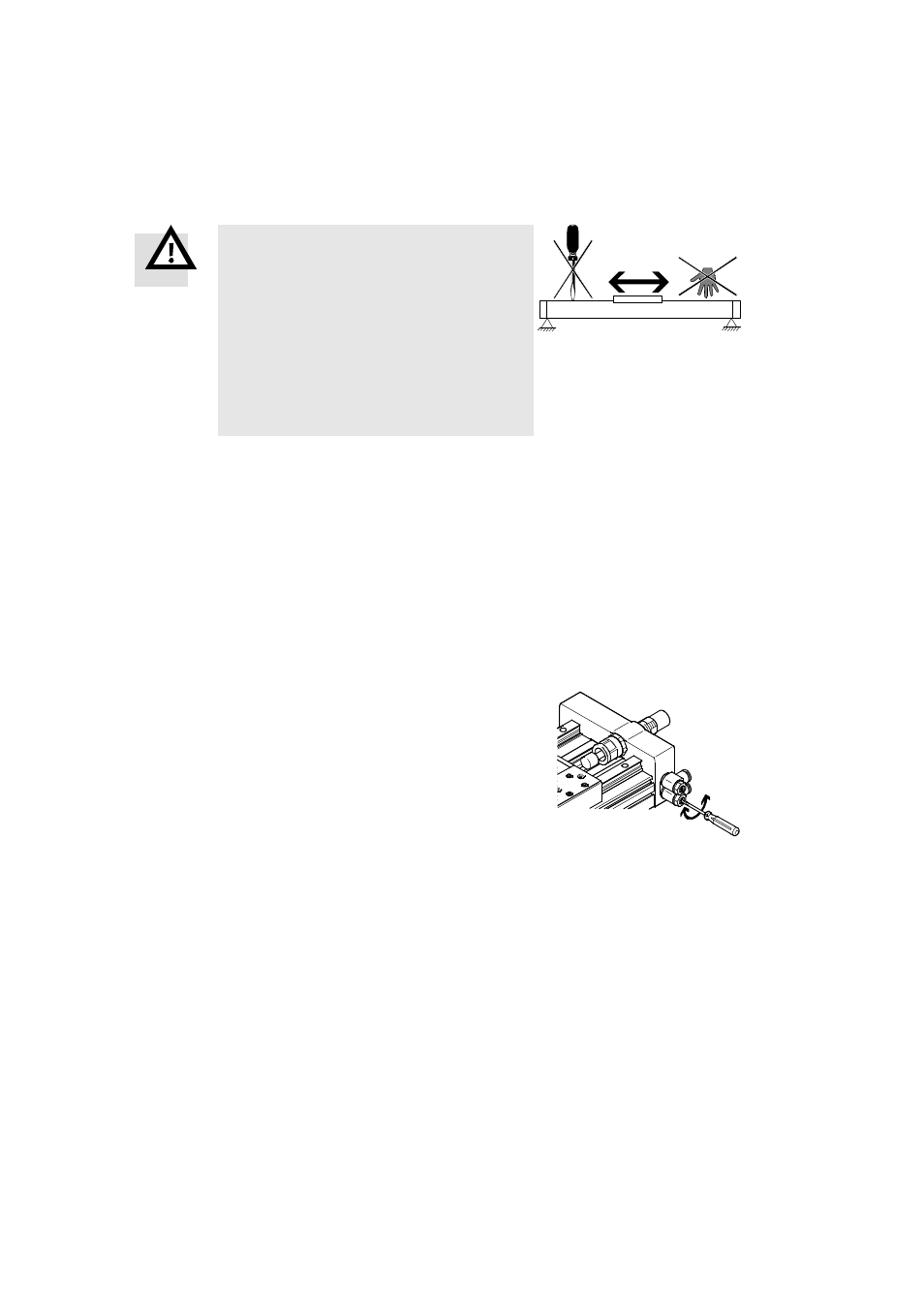

Warning

Moving masses can cause personal injury and

material damage (risk of crushing).

•

Make sure that, in the path of the moving

components

–

nobody can place his/her hand

(e.g. through a protective guard),

–

there are no foreign objects.

It should not be possible to touch the DGC-HD

until the load has come to complete rest.

Fig. 10

At medium or large useful loads or high speeds:

•

Use the sizing software “DGC-QuickCalc” for pneumatic drives in the support portal

(

www.festo.com/sp).

•

Make sure that cushioning devices are of sufficient size.

Without external cushioning devices the DGC-HD will withstand maximum speeds and useful loads

in accordance with catalogue specifications or table (

11 Technical data).

Even in the event of malfunctions, the limit values must not be exceeded.

Carrying out commissioning

•

Slowly pressurise the system as a whole.

In this way you will prevent sudden uncontrolled movements.

For slow start-up pressurisation, use start-up valve type HEL.

1. Close the one-way flow control valves

–

for both sides at first completely

–

then one turn open again.

2. Pressurize the DGC-HD as follows:

–

At first on both sides simultaneously. The slide will then

move slightly to a centre of equilibrium.

–

Then exhaust the DGC-HD on one side. In this way you can

avoid peak loadings on the DGC-HD and in the compressed

air network.

Fig. 11

3. Start a test run.

4. Check whether the speed of the slide has to be modified.

5. Open up the one-way flow control valves slowly until the desired slide speed is reached.

As intended, the slide should reach the end position without striking hard against it or bouncing

back.