Festo DAPS..R..-F.. User Manual

Quarter turn actuator daps..r..-f

Quarter turn actuator

DAPS..R..-F..

Festo AG & Co. KG

Postfach

D-73726 Esslingen

+49 711 347-0

www.festo.com

(en) Operating instructions

8030408

1309g

[8030416]

Original: de

Quarter turn actuator DAPS..R..-F..

English

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

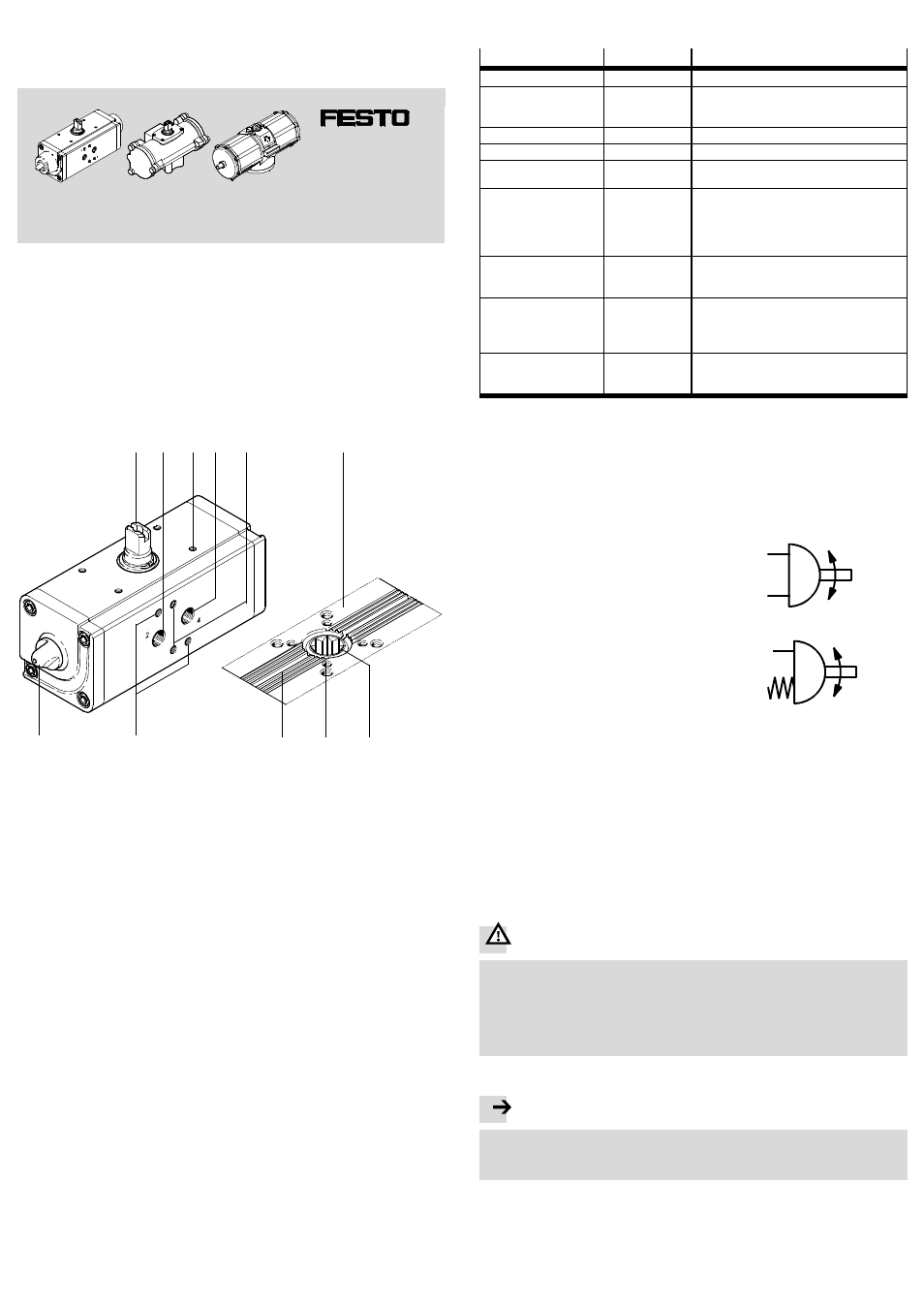

Control sections and connections

9

1 2

3

4

5

6

7

8

aJ

aA

1 Transmission shaft (shaft groove

shows the process valve position –

here closed)

2 Compressed air supply port 2 (A)

3 Four mounting threads – such as

for mounting the limit switch or

sensor box

4 Compressed air supply port 4 (B)

5 Mounting thread for threaded pin

for aligning the NAMUR valve

6 View from below – flange to

ISO 5211

7 Star-shaped coupling for seating

of the square of a process valve

8 Mounting thread

9 Some product designs:

leakage groove

aJ Mounting thread for pneumatic

NAMUR switching valve

aA Only for product variants with the

ability to adjust the end position:

lock nut for securing the set end

position.

Fig. 1

Operating elements and connections – example of standard design,

double-acting

2

Design

Quarter turn actuators of the DAPS series are compact in design and have simple

and robust mechanics with little wear and tear. The design of the product is de-

pendent on the product design and may differ from the representation shown in

Fig. 1 (

Fig. 1).

Through the housing, a shaft is guided outward on both sides. Through this, the

reaction torque is transmitted to a process valve (

Fig. 1,

6 ) and, if applicable,

a limit switch or sensor box (

Fig. 1,

1 ).

The flange to the process valve is normally designed in accordance with ISO 5211

(

section 12). Four mounting threads on the top are used for mechanical attach-

ment of a limit switch or sensor box (

Fig. 1,

3 ). The housing side has a hole

pattern for valve attachment in accordance with VDI/VDE 3845 (NAMUR).

The housing of some quarter turn actuators has, on the process valve port side, a

leakage groove (

Fig. 1,

9 ) through which the leakage of an untight process

valve can escape.

The product is available in various designs. Depending on the version, the DAPS is

designed as a single-acting or double-acting quarter turn actuator. The single-act-

ing design with spring return is available with different spring strengths for various

supply pressures.

These operating instructions describe the following product variants:

Features

Type codes

Description

Series

DAPS-

Quarter turn actuator

Size or nominal torque in

Nm

0008-

…

8000-

Nominal torque 8 Nm

…

Nominal torque 8000 Nm

Swivel angle in degrees

090-

90°

Closing direction

R

Closes to right

Mode of operation

- (without)

S

Double-acting

Single-acting

Spring strength (with

mode of operation S)

(without)

1-

2-

3-

4-

(Omitted for double-acting)

Spring strength for connection pressure 2.8 bar

Spring strength for connection pressure 3.5 bar

Spring strength for connection pressure 4.2 bar

Spring strength for connection pressure 5.6 bar

1st flange hole pattern

F03

…

F25

Flange hole pattern F03

…

Flange hole pattern F25

2nd flange hole pattern

(without)

05

…

16

No second flange hole pattern

Flange hole pattern F05

…

Flange hole pattern F16

Design

(without)

-T6

-CR

Standard design (-20 °C to + 80 °C)

Low temperature (-50 °C to +60 °C)

Stainless steel (-20 °C to + 80 °C)

Fig. 2

Type code (e.g. DAPS-0120-090-R-F0507-CR)

Select suitable accessories (e.g. adapter kits) from the catalogue

(www.festo.com/catalogue).

3

Function

The piston movement of the DAPS is converted to a rotary movement by means of

yoke kinematics (Scotch yoke). These kinematics are only effective within an angle

of approx. 90°.

For double-acting quarter turn actuators:

Pressurising and venting of the cylinder chambers

cause the piston in the DAPS to move back and forth.

The

linear motion of the piston is transformed into a swiv-

el motion of the transmission shaft.

Fig. 3

For single-acting quarter turn actuators:

Return is through spring force.

Product designs with different spring strengths are

available (

Fig. 2).

Fig. 4

The screwed-on processing valve absorbs the reaction torque of the quarter turn

actuator. The torques permitted in accordance with the technical data

(

catalogue www.festo.com/catalogue) apply here.

4

Application

The DAPS quarter turn actuator is intended to activate right-closing process

valves, such as ball valves and butterfly valves with a rotation angle from 0° (valve

closed) to 90° (valve open).

It is completely tailored to the requirements of the processing industry and is suit-

able for control of media-flow process valves in fluid engineering systems.

5

Transport and storage

Ensure the following storage conditions: short storage times in cool, dry, shaded

and corrosion-resistant locations.

Warning

Danger of crushing! Danger of shearing!

The DAPS weighs up to about 183 kg, depending on the product version.

Body parts can be crushed or cut off if the product falls.

• For product versions weighing more than 12 kg, always use appropriate load-

carrying equipment in order to handle the product safely during transport and

assembly.

6

Requirements for product use

Note

Incorrect handling can result in malfunctions.

• Make sure that all the instructions in this section are always observed. The

product will then function correctly and safely.

• Compare the limit values specified in these operating instructions with your

actual application (e.g. pressures, forces, torques, masses, speeds, temperat-

ures). The product can be operated in compliance with the relevant safety

guidelines only if the load limits are observed.

• Ensure that all applicable regulations for your location are adhered to, e.g. of

the trade association or national institutions.

Document Outline

- Quarter turn actuator DAPS..R..-F.. English

- 1 Control sections and connections

- 2 Design

- 3 Function

- 4 Application

- 5 Transport and storage

- 6 Requirements for product use

- 7 Installation

- 8 Commissioning

- 9 Maintenance and care

- 10 Disassembly

- 11 Troubleshooting

- 12 Technical data