7 service and maintenance, 7service and maintenance – Festo DGC-HD User Manual

Page 26

DGC-HD

26

Festo – DGC-HD – 1304NH English

For precision adjustment of the stroke:

Warning

The DGC-HD will be damaged if the DGC is operated without the stop sleeve (H) and the

lock nut (K).

•

Assemble the cushioning components together only with the stop sleeve (H) and the

lock nut (K).

1. Loosen the lock nut (K).

2. Screw the cushioning element in or out.

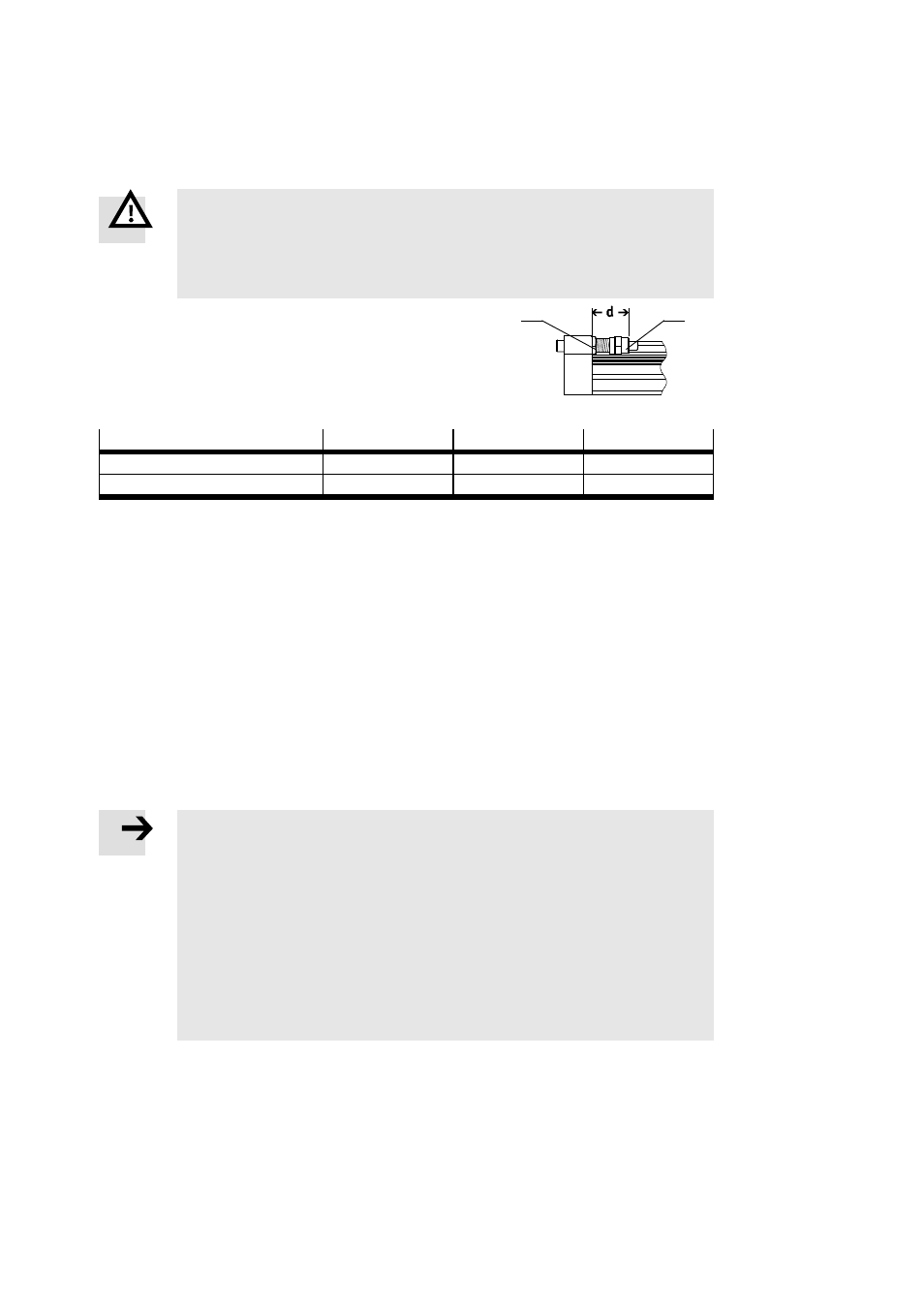

For reasons of stability, distance d (

Fig. 12) must not exceed

the values in the following table.

3. Tighten the lock nuts (K) with the following tightening torque.

Fig. 12

H

K

Size

18

25

40

Distance d

[mm]

27.3 … 52.3

31 … 56

41 … 76

Tightening torque

[Nm]

20

35

60

Tab. 5

If the effective load or dynamic response is modified:

•

Check whether other cushioning components are required.

7

Service and maintenance

For cleaning and maintenance:

•

Clean the band system and guide rail as required with a soft cloth.

Any media which will not damage the material may be used as cleaning agents.

•

Avoid cleaning agents which will damage the belt system, which is made of PU.

Excessive rubbing or the use of grease-solvent cleaning agents (e.g. soap suds) will damage the

grease layer.

Note

The lubrication interval S

int

is dependent on the load acting on the product.

•

Halve the lubrication interval S

int

(

Fig. 13) if any of the following situations apply:

–

dusty and dirty environment

–

nominal strokes

> 2000 mm

–

speeds

> 2 m/s

–

positioning profile:

Z delta operation (frequent acceleration and braking)

–

ambient temperatures

> 40 °C

–

product has been in operation for

> 3 years.

If more than one of the above criteria are simultaneously met, the normal lubrication

interval must be divided by four.