8 repair, 9 accessories, 8repair – Festo DGC-HD User Manual

Page 27: 9accessories

DGC-HD

Festo – DGC-HD – 1304NH English

27

•

Grease the following components:

Bearing guide

Guide rail

Lubricating point (

Fig. 1)

Lubrication hole

3

Surface

2

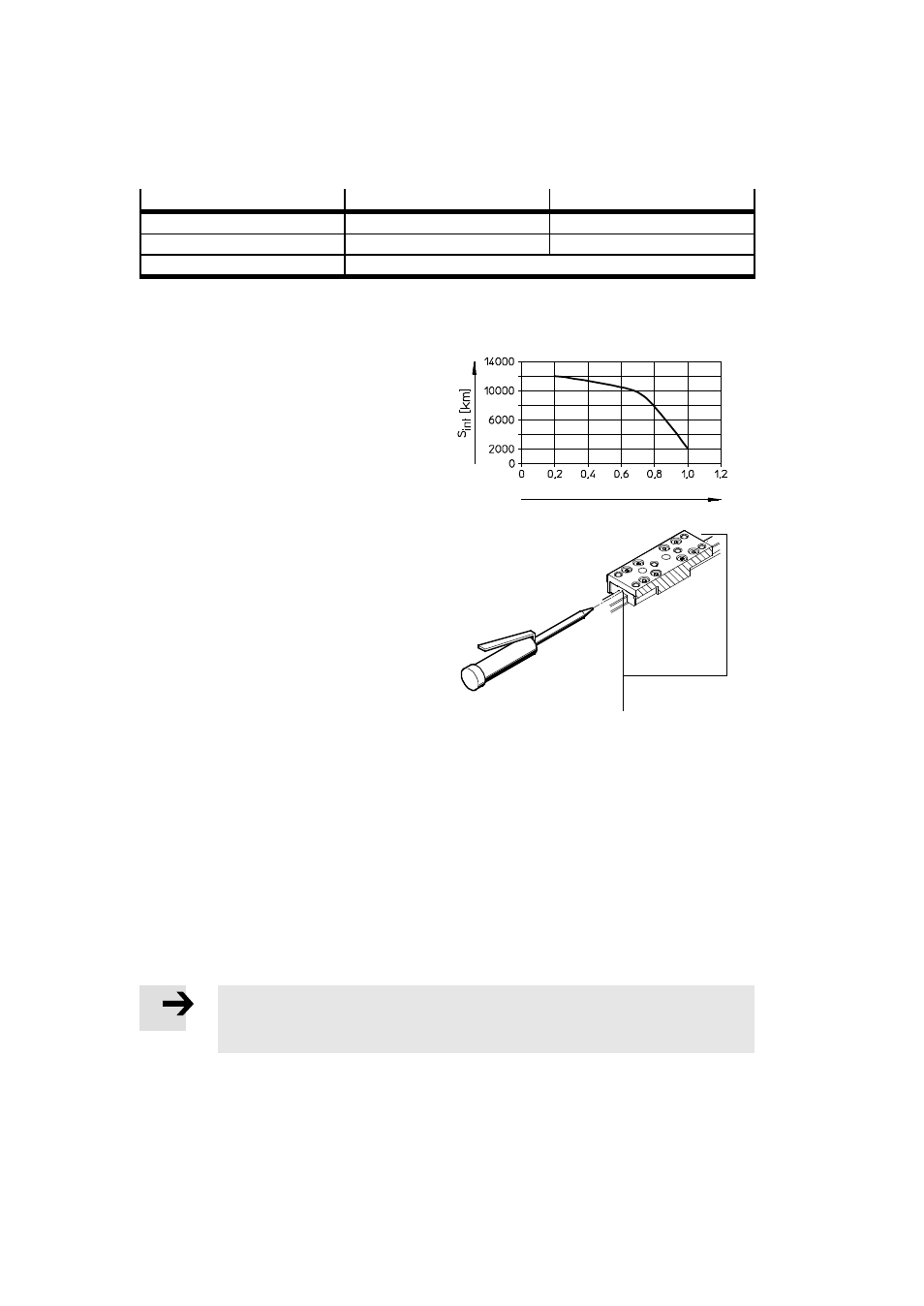

Lubrication interval

(

Fig. 13)

As required

1)

Grease

2)

Roller bearing grease

1)

Or if there is no longer a layer of grease on the component

2)

Grease gun, blast pipes and grease (

9 Accessories)

Tab. 6

To grease the

bearing guide:

1. Calculate the load comparison factor fv with

the aid of the formula for combined loads

(

11 Technical data) and determine the lub-

ricating interval S

int

from it (

Fig. 13).

Fig. 13

fv

2. Grease the bearing guide on both sides at all

lubrication holes

3.

3. Move the slide the complete travel distance

during lubrication in order to distribute the

grease evenly inside.

Alternatively, Festo offers a service inspection

which includes lubrication.

Otherwise, the DGC-HD is maintenance-free.

Fig. 14

3

8

Repair

•

Recommendation: Send the DGC-HD to our repair service.

This way the required fine tuning and tests will be taken into special consideration.

•

Information about spare parts and accessories can be found at: (

www.festo.com/spareparts).

To replace cushioning elements:

•

Observe the section “For precision adjustment of the stroke” (

6 Commissioning).

9

Accessories

Note

•

Please select the corresponding accessories from our catalogue

(

www.festo.com/catalogue).