3 how to drain transmission, 4 how to back flush oil cooler, 5 transmission removal – SkyTrak 6036 Service Manual User Manual

Page 89: 6 transmission replacement, 7 internal servicing, 8 installation

Section 7

Transmission

Model 6036/6036T S/N 9B0500 thru 14833

7-3

1

2

5

3

6

4

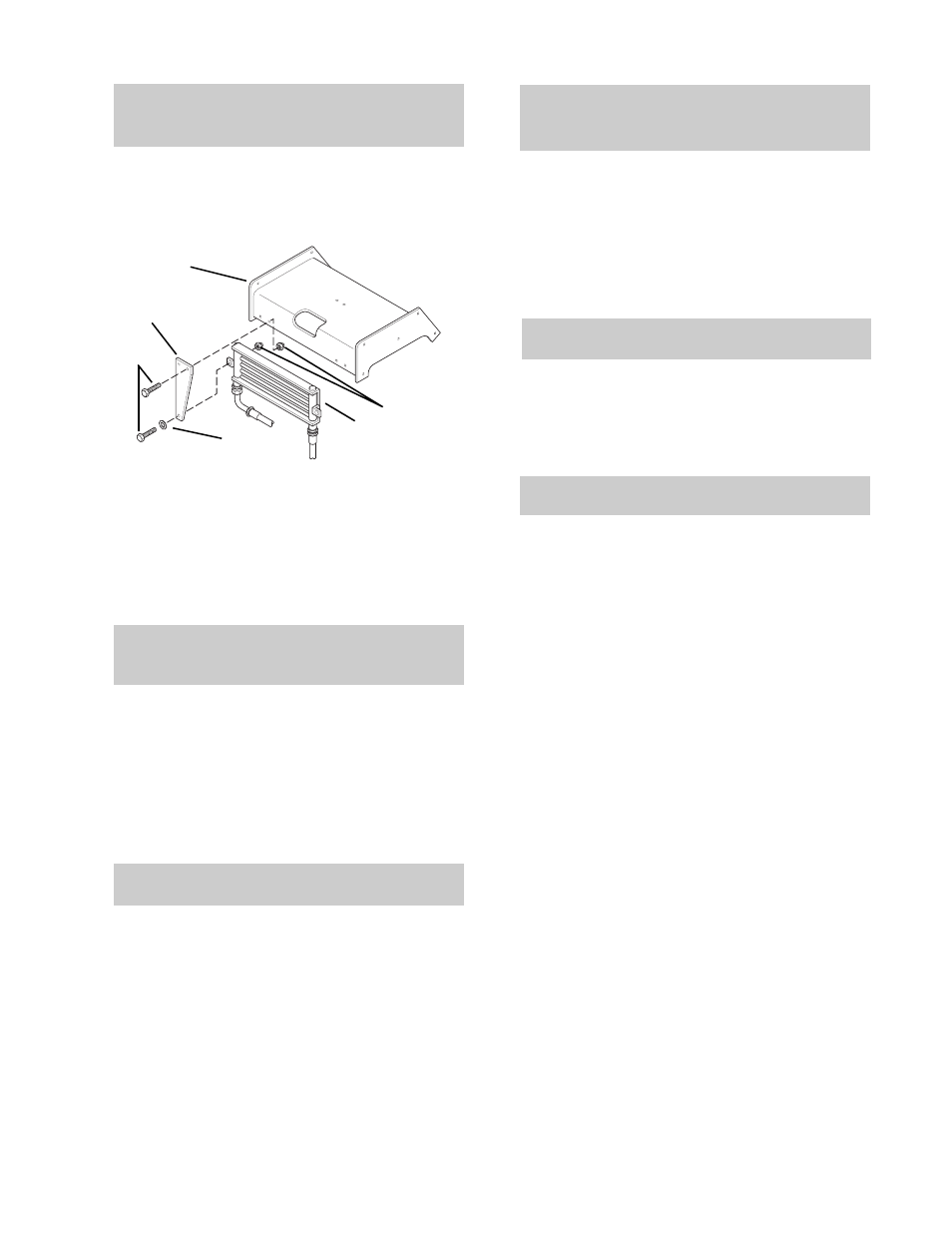

4.

Flat Washer

5.

Oil Cooler Support

6.

Rear Support

Fig. 7.4 Transmission Oil Cooler

1.

Lock Nut

2.

Transmission Oil Cooler

3.

Capscrew, hex hd

MA0321

7.3

HOW TO DRAIN

TRANSMISSION

The procedure for draining the transmission is de-

scribed in paragraph 7.1.3.

7.4

HOW TO BACK FLUSH

OIL COOLER

The transmission oil cooler, Fig. 7.4, is mounted

behind the radiator. Periodically disconnect and

back flush the oil cooler with oil and compressed

air until all foreign material has been removed. If

necessary, remove oil cooler from forklift and

clean it using oil, compressed air and steam.

IMPORTANT: DO NOT use flushing compounds

for cleaning purposes.

7.5

TRANSMISSION REMOVAL

Please refer to paragraph 8.6 for engine and

transmission removal instructions (they are re-

moved as a single unit).

7.6

TRANSMISSION

REPLACEMENT

If the transmission is to be replaced as a complete

assembly, detach and transfer the following:

• Tandem Pump

• Transmission Temperature Switch

• Transmission Connector Kit (from valve)

• Two Side Mount Brackets

(Neutral Start Switch comes with new

transmission)

7.7

INTERNAL SERVICING

If servicing the transmission internally, the tandem

pump may require removal for disassembly.

Refer to the enclosed "Clark 18000 Powershift

Transmission Maintenance and Service Manual"

when servicing the transmission internally.

7.8

INSTALLATION

Please refer to paragraph 8.8 for engine and

transmission installation instructions (they are in-

stalled as a single unit).