SkyTrak 6036 Service Manual User Manual

Page 135

Section 8B

Cummins Engine

Model 6036/6036T S/N 9B0500 thru 14833

8B-15

• U.S.A.—Engineering Standard

GM6038-M.

• U.K.—BS 3151: 1959: Ethanediol Anti-

freeze Type B with Sodium Benzoate and

Sodium Nitrite Inhibitors

• Australia—AS 2108-1977: Antifreeze

Compounds and Corrosion Inhibitors for

Engine Cooling Systems

2.

There is an advantage to using antifreeze

even when frost protection is not necessary.

Antifreeze protects against corrosion and also

raises the boiling point of the coolant. A 50

percent concentration of antifreeze is pre-

ferred, but if this much protection is not

required, a 33 percent concentration can be

used. NEVER USE MORE THAN A 65

PERCENT CONCENTRATION UNDER ANY

CONDITION. Where frost protection will

never be required, add an approved corrosion

inhibitor to clean soft water. Change the

water/corrosion inhibitor every six months or

according to the inhibitor manufacturer’s

recommendations.

• DO NOT USE HARD WATER in the

cooling system. Hard water, or water with

high levels of calcium and magnesium

ions, encourages the formation of silica

gel formations, especially after a number

of heating and cooling cycles. These gel

formations can result in loss of cooling or

heating in radiators and cab heater cores

by coating and plugging the tubes. The

formations usually deposit in the cooler

section of the cooling system, such as the

radiator bottom tank.

• USE SOFT, DISTILLED OR DEIONIZED

WATER to reduce the potential and the

severity of silicate dropouts.

IMPORTANT: If you use water without a corro-

sion inhibitor, rust will form and plug the small

holes in the head gasket. These holes are orifices

and their size is critical. Do not enlarge the size of

the orifices. To do so will disturb the coolant flow

and will not solve an overheating problem. If you

use water without a corrosion inhibitor for even a

relatively short period, the cup plugs will rust

through, allowing coolant to leak. An incorrect or

malfunctioning radiator cap can result in the loss

of coolant and the engine running hot. Any

sudden loss of coolant from a heavily loaded

engine can result in severe damage to the pistons

and cylinder bore.

NOTE: Some corrosion inhibitor mixtures contain

soluble oil which can have an adverse effect on

some types of water hose.

8B.9.2 Radiator Pressure Cap

The system is designed to use a radiator pressure

cap to prevent the boiling of the lubricant. For a

210 °F (99 °C) system use a 7 psi (48 kPa)

radiator cap. An incorrect or malfunctioning cap

can result in the loss of coolant and the engine

running hot.

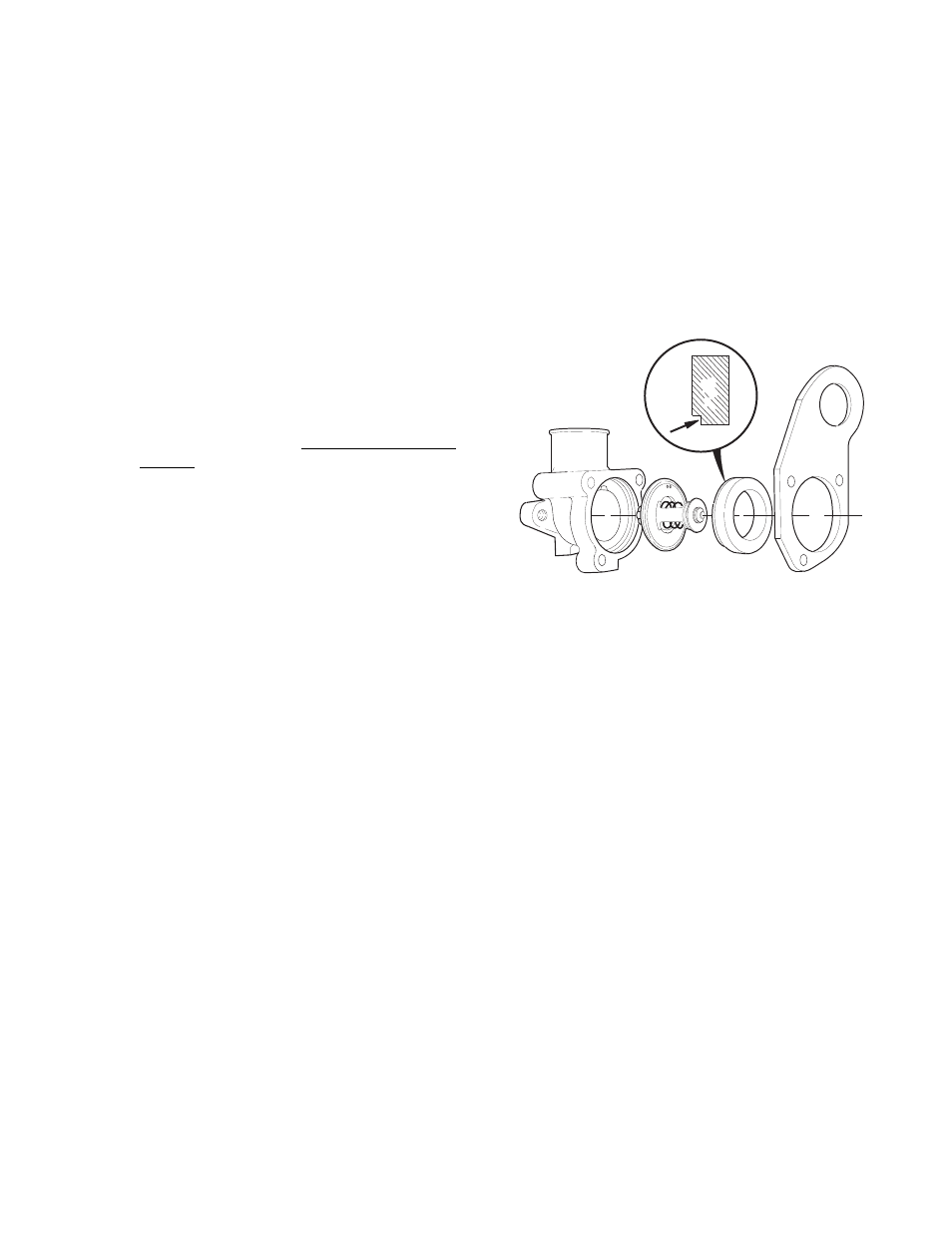

8B.9.3 How to Replace Thermostat

If it becomes necessary to replace the thermostat,

Fig. 8B.38, follow these steps.

1.

Preparatory steps:

• Drain 2.1 quarts (2 liters) of coolant.

• Remove the radiator hose from the outlet

connection.

• Remove the drive belt.

• Disconnect the negative battery cable.

2.

Loosen the alternator link capscrew on the

bottom of the alternator. Remove the alterna-

tor mounting capscrew and lower the alterna-

tor.

3.

Remove the thermostat housing, gasket, lifting

bracket and thermostat.

4.

Remove the thermostat and clean the gasket

surfaces. DO NOT let any debris fall into the

thermostat cavity when cleaning gasket

surfaces.

IMPORTANT: Always use the correct thermostat

and never operate the engine without a thermo-

stat.

MA1500

Fig. 8B.38 Thermostat Housing